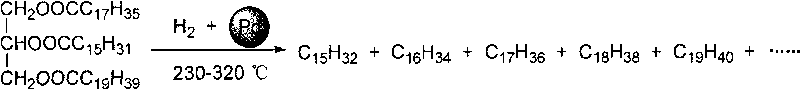

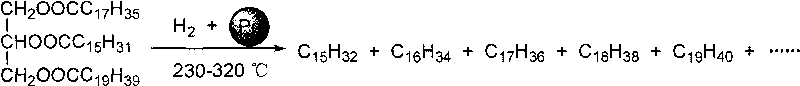

Method for preparing diesel components by catalytic hydrodeoxygenation of vegetable oil

A technology for vegetable oil and catalytic hydrogenation, which is used in the preparation of liquid hydrocarbon mixtures, petroleum industry, biological raw materials, etc., can solve the problems of less catalyst preparation process, harsh reaction conditions, and low calorific value of products, and achieves easy recycling, The effect of less solvent consumption and high combustion calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1.5g sunflower oil, 0.5g 2%Pd / BaSO 4 Catalyst and 30mL of n-hexane were added to a 100mL reaction kettle, filled with hydrogen, the initial hydrogen pressure was 3.0MPa, stirring and heating were started, and the reaction was stopped after 7 hours of reaction at 270°C. After cooling to room temperature, the liquid product and the catalyst were automatically separated to obtain a clear Diesel components. Quantitative detection of the product by high-performance liquid chromatography and gas chromatography shows that the conversion rate of the raw material sunflower oil can reach 100%, and the total output of normal alkanes is 1.01g. The product composition is shown in the table below:

[0023]

Embodiment 2

[0025] 1.0g sunflower oil, 0.4g 5%Pd / BaSO 4 Add the catalyst and 15mL of n-octane into a 100mL reactor, fill it with hydrogen, start the stirring and heating at an initial hydrogen pressure of 5.0MPa, and stop the reaction after reacting at 320°C for 5 hours. diesel components. Quantitative detection of the product by high-performance liquid chromatography and gas chromatography shows that the conversion rate of the raw material sunflower oil can reach 98%, and the total output of normal alkanes is 0.63g. The product composition is shown in the table below:

[0026]

Embodiment 3

[0028] 1.5g peanut oil, 0.3g 5%Pd / BaSO 4 Add the catalyst and 25mL of n-heptane into a 100mL reactor, fill it with hydrogen, start the stirring and heating at an initial hydrogen pressure of 6.0MPa, and stop the reaction after reacting at 240°C for 12 hours. After cooling to room temperature, the liquid product and the catalyst are automatically separated to obtain clarification diesel components. Quantitatively detect the product by high performance liquid chromatography and gas chromatography respectively, it can be seen that the conversion rate of the raw material peanut oil can reach 99%, and the total output of normal alkanes is 1.00g. The product composition is shown in the table below:

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com