System and method for respectively recovering fermented industrial waste water according to quality

A technology for separation and reuse of industrial wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, electrochemical water/sewage treatment, etc., can solve the problems of long start-up time and short residence time, and achieve biochemical performance improvement, good nitrogen and phosphorus removal ability, and good mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

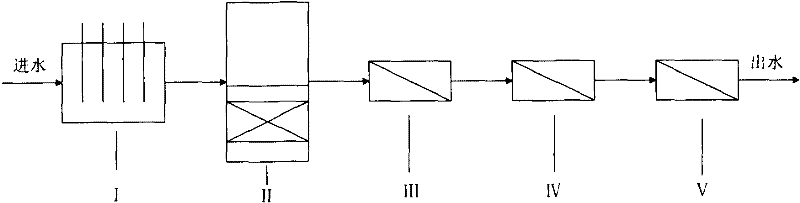

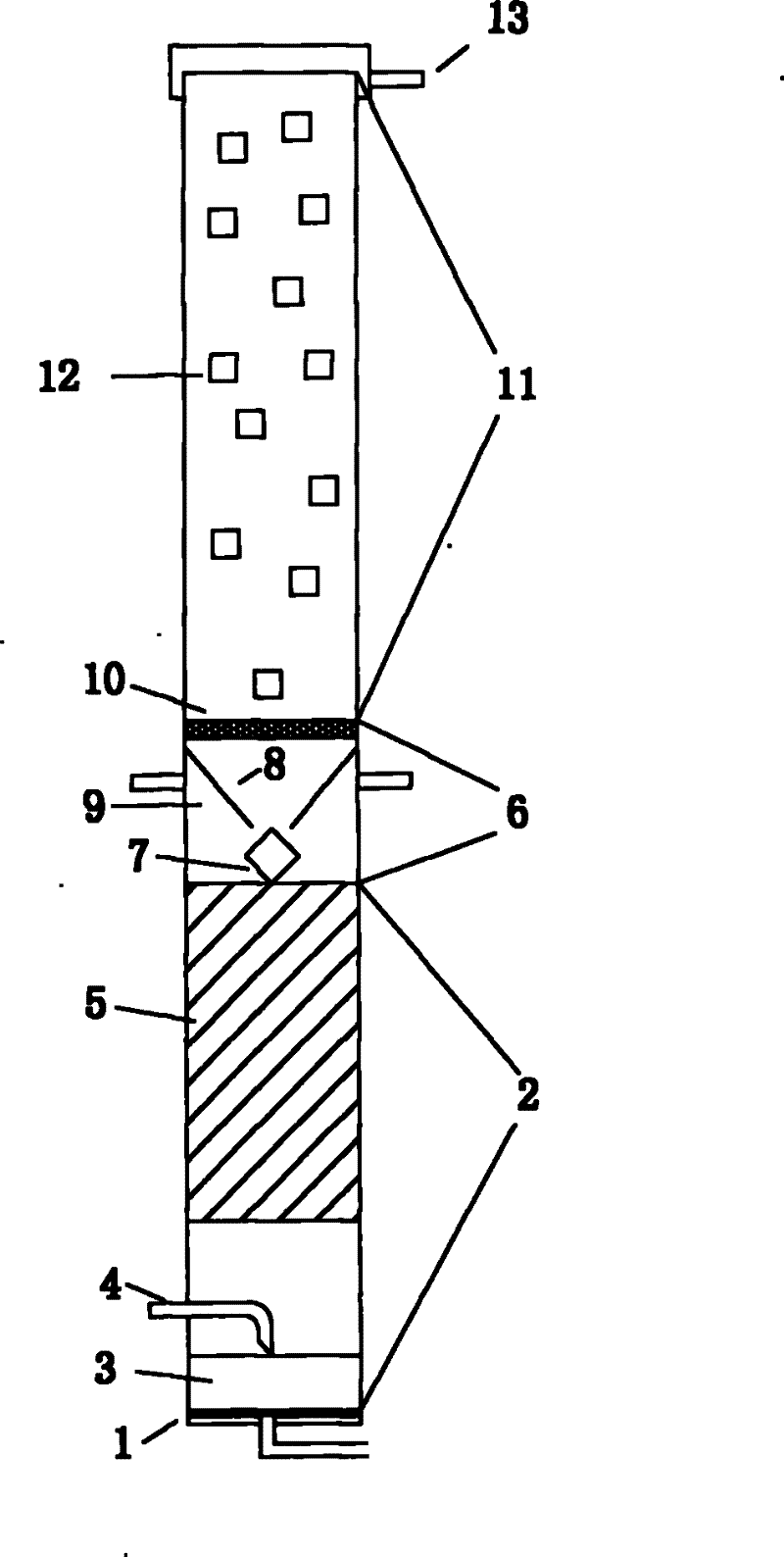

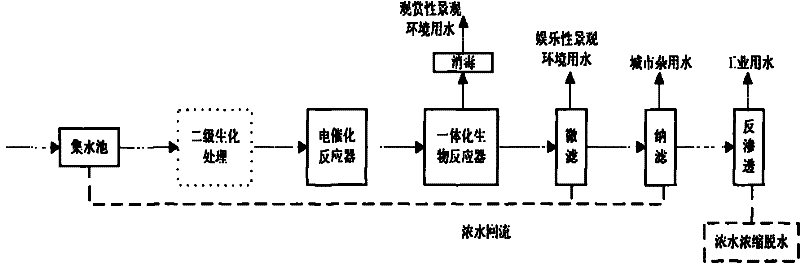

Method used

Image

Examples

Embodiment 1

[0050] Example 1: The biochemical treatment effluent of a vitamin C pharmaceutical factory was regenerated and reused with the present invention. The water quality status is shown in Table 1:

[0051] Table 1 Water quality indicators of biochemical treatment effluent from vitamin C pharmaceutical factory

[0052] COD Cr

mg / L

BOD

mg / L

NH 3 -N

mg / L

TN

mg / L

TP

mg / L

SS

mg / L

NTU

Chroma

Degree

mg / L

pH

380

75

1.78

79.39

0.15

22

9

110

5600

7.2

[0053] The process parameters and effluent quality of each process section are as follows:

[0054] (1) Electrocatalytic oxidation plus integrated bioreactor

[0055] The electrocatalytic oxidation process parameters are as follows: the anode material used in the electrocatalytic oxidation reactor is graphite, the cathode material is stainless steel, the pole plate is set perpendicular to the ground, and the current density is 50A / m 2 , The distance between the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com