Method for biofiltration processing of soot exhaust gas on basis of roofing greening nutritive soil

A technology of roof greening and biological filtration, which is applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of land occupation, unstable initial operation, single strain of bioreactor, etc. Market development prospects, the effect of high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

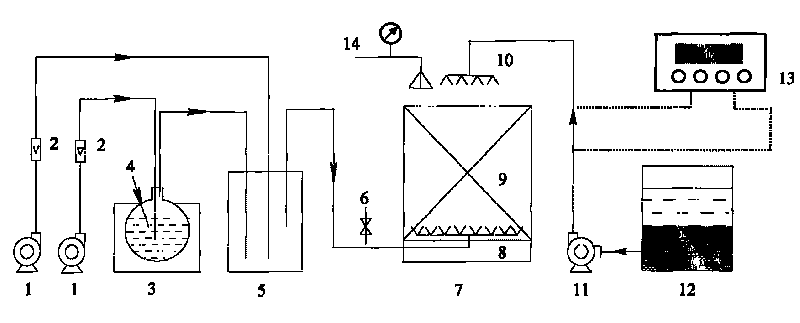

[0033] The embodiment and working principle of the present invention are as follows: oil fume exhaust gas containing VOC concentrations of 15.0mg / L, 20.0mg / L, 25.0mg / L, 30.0mg / L, 35.0mg / L and 40.0mg / L, based on the roof The biofiltration treatment experiment is carried out on the nutrient soil layer of the greening project. The main reactor of the treatment device is divided into a support layer, an air distribution partition layer, a nutrient soil layer and a turf layer. The nutrient soil layer is composed of various substances (cinder, loess, peat, and perlite are mixed in a volume ratio of 1:1:1:0.2, and the diameter of the mixed particles is 2-50mm). Exhaust gas enters from the bottom, disperses through the inverted air distribution plate to form tiny bubbles, and fully contacts with the biofilm on the nutrient soil layer. After completing the gas-liquid mass transfer process, the pollutants are decomposed into CO under the action of microbial oxidation and decomposition. ...

Embodiment 2

[0038] The embodiment and working principle of the present invention are as follows: other conditions are the same as in Example 1, and at a VOC concentration of 30.0 mg / L, see Table 2 for the effects of different residence times (EBRT) on the fume exhaust gas treatment results.

[0039] Table 2: Results of oil fume exhaust gas treatment at different residence times (EBRT)

[0040]

[0041]The results in Table 2 show that, when the residence time (EBRT) is 10s, 15s, 20s, 25s, 30s and 35s, the removal rate of VOC in oil fume by this process is 76.5%, 84.5%, 90.5%, 92.7%, 94.2% respectively and 96.3%.

Embodiment 3

[0043] The embodiment and working principle of the present invention are: other conditions are the same as in Example 1, the residence time (EBRT) is 20s, and the VOC concentration is 30.0mg / L.

[0044] Table 3: Results of oil fume exhaust gas treatment at different temperatures

[0045]

[0046]

[0047] The results in Table 3 show that at temperatures of 10°C, 15°C, 20°C, 25°C, 30°C, 35°C, 40°C, 45°C, and 50°C, the removal rates of oil fume by this process are 64.5%, 72.5%, and 80.5%, 88.4%, 92.5%, 93.6%, 70.3%, 62.6% and 52.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com