Cu-Cr-S ternary thermoelectric material and preparation method thereof

A thermoelectric material, cu-cr-s technology, applied in the direction of thermoelectric device junction lead-out material, etc., can solve the problems of unreported thermoelectric materials, harsh reaction conditions, high energy consumption, etc., and achieves low requirements for equipment and preparation environment , the preparation process is simple and the raw materials are cheap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

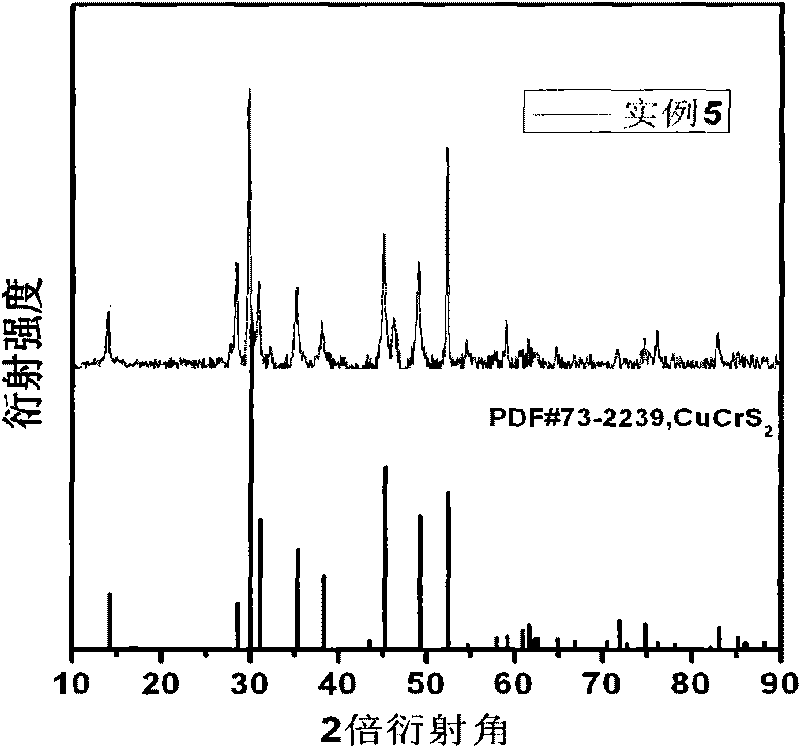

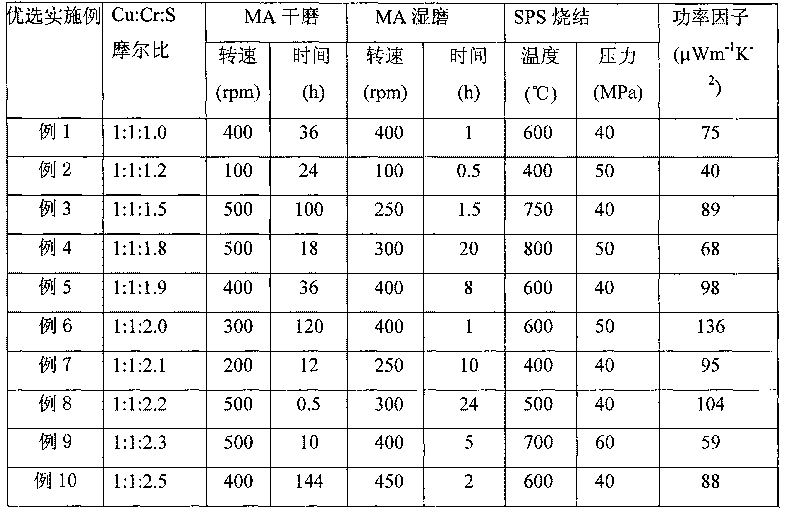

[0012] First prepare Cu-Cr-S ternary nanopowder with mechanical alloying method, this method is to mix Cu powder (mass percentage ≥ 99.9%), Cr powder (mass percentage ≥ 99.9%) and S powder (mass percentage ≥ 99.5%) According to the general chemical formula CuCrS x (1.0≤x≤2.5) ratio, mixed into a planetary high-energy ball mill, mechanically alloyed under the protection of inert gas argon, dry-milled to synthesize the compound, then wet-milled, and dried to obtain CuCrS x powder, the dried powder is subjected to spark plasma sintering to obtain a bulk material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com