Novel environment-friendly heat insulating coating and preparation method thereof

A thermal insulation coating and environmental protection technology, applied in epoxy resin coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of high cost and development limitations of vacuum ceramic microspheres, and reduce the poor thermal insulation effect, Inexpensive and resource-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

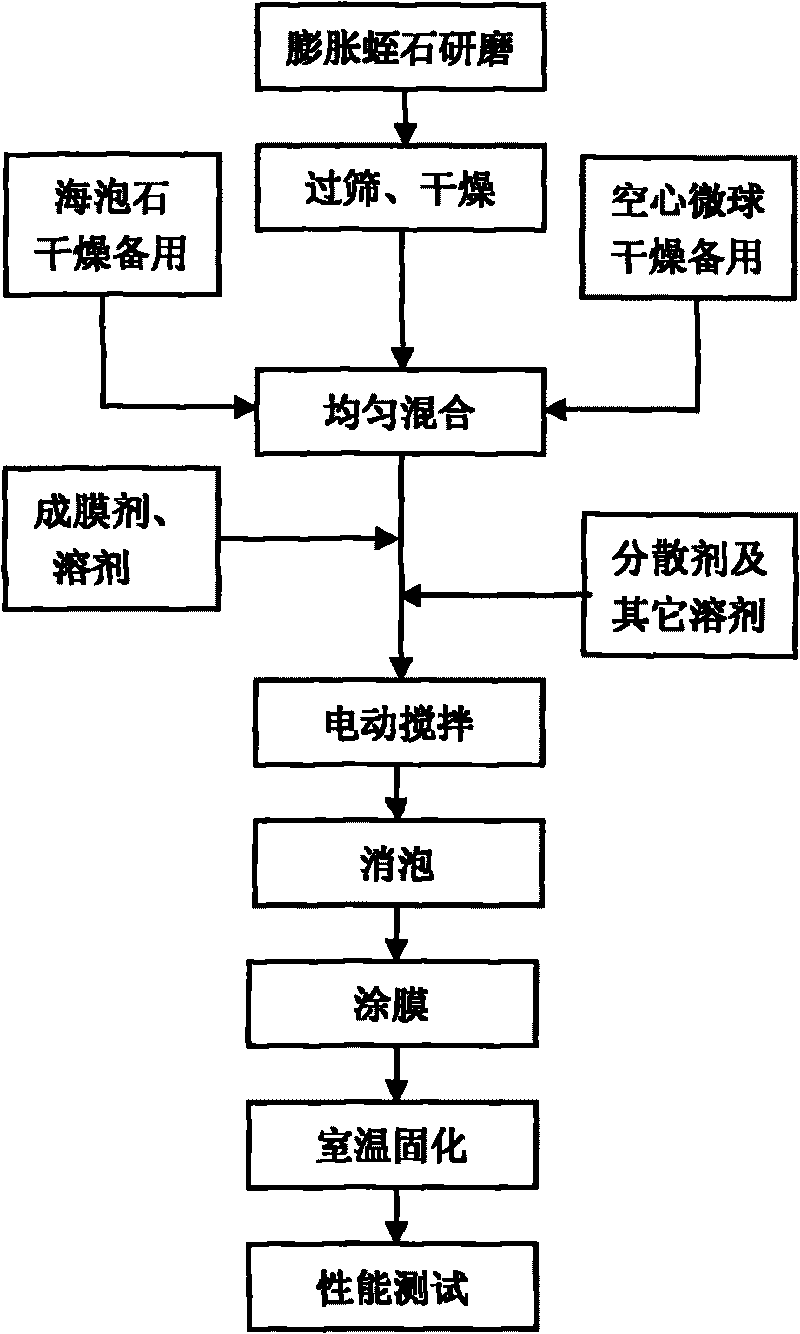

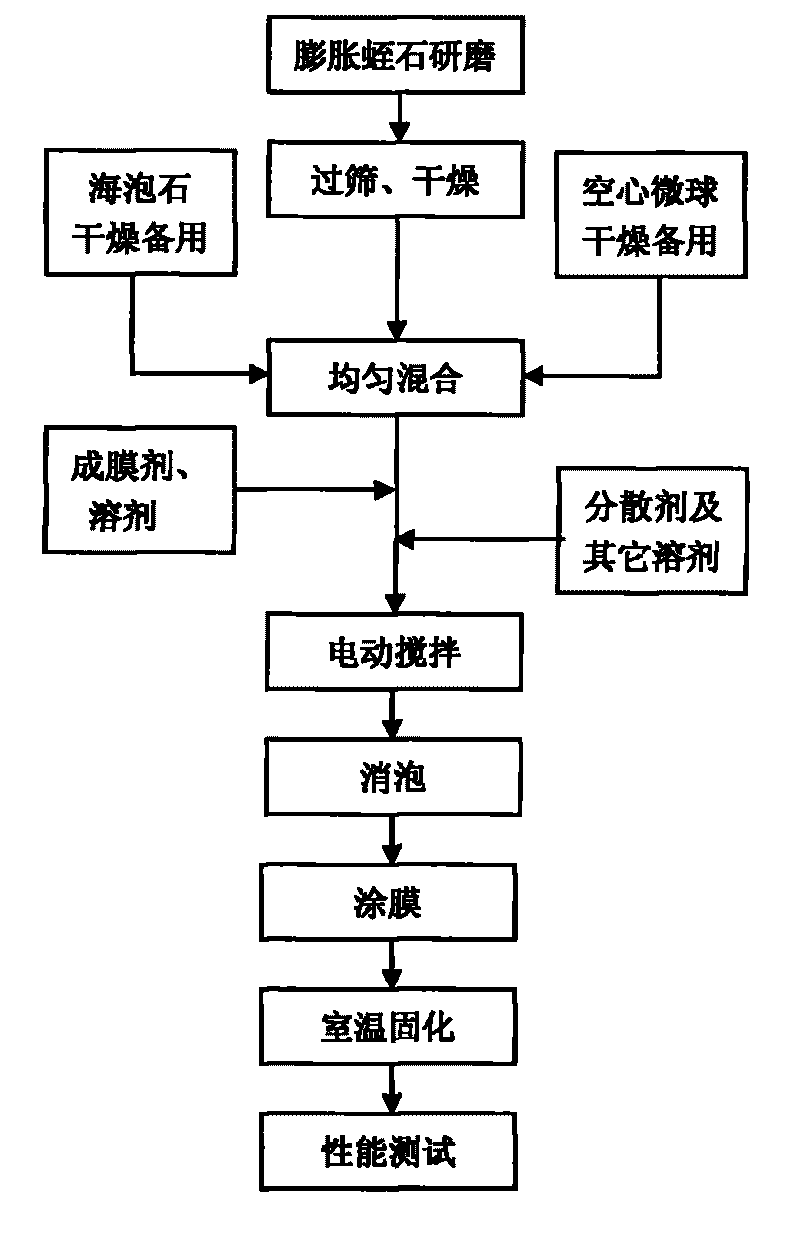

Method used

Image

Examples

Embodiment 1

[0028] (1): Grind the expanded vermiculite with a sand mill for 1 hour, vacuum filter it, and grind it with a mortar after drying. Pass the ground expanded vermiculite through a 200-mesh sieve, and then place it in a blast oven at 100°C for 4 hours. Desiccator preservation, spare;

[0029] (2): Dry the sepiolite at 100°C for 4 hours, store in a desiccator, and set aside;

[0030] (3): Dry the hollow microspheres at 100°C for 4 hours, store in a desiccator, and set aside;

[0031] (4): Weigh 44g of expanded vermiculite, 20g of sepiolite, and 20g of hollow microspheres prepared in step (1), step (2), and step (3) respectively, and mix them well to obtain Group A Minute;

[0032] (5): Add 200g of silicone-modified acrylic resin, 100g of water, 2g of wetting agent, 5g of dispersant, 2g of defoaming agent, 2g of silane coupling agent, and 5g of other additives in order, and mix well to obtain B component;

[0033] (6): Fully mix components A and B, stir at room temperature for ...

Embodiment 2

[0037] (1): Grind the expanded vermiculite with a sand mill for 2 hours, vacuum filter, dry and grind in a mortar, pass the ground expanded vermiculite through a 400-mesh sieve, and then dry it in a blast oven at 105°C for 4.5 hours , stored in a desiccator, for use;

[0038] (2): Dry the sepiolite at 105°C for 4.5 hours, store in a desiccator, and set aside;

[0039] (3): Dry the hollow microspheres at 105°C for 4.5 hours, store in a desiccator, and set aside;

[0040] (4): Weigh 40g of expanded vermiculite, 30g of sepiolite, and 30g of hollow microspheres prepared in step (1), step (2), and step (3) respectively, and mix them well to obtain Group A Minute;

[0041] (5): Add 200g of silicone-modified acrylic resin, 100g of water, 3g of wetting agent, 6g of dispersant, 3g of defoaming agent, 3g of silane coupling agent, and 5g of other additives in order, and mix well to obtain B component;

[0042] (6): Fully mix components A and B, stir at room temperature for 1 hour, an...

Embodiment 3

[0046] (1): Grind the expanded vermiculite with a sand mill for 1 hour, vacuum filter it, and grind it in a mortar after drying. Pass the ground expanded vermiculite through a 400-mesh sieve, and then dry it in a blast oven at 105°C for 4.5 hours. , stored in a desiccator, for use;

[0047] (2): Dry the sepiolite at 105°C for 4.5 hours, store in a desiccator, and set aside;

[0048] (3): Dry the hollow microspheres at 105°C for 4.5 hours, store in a desiccator, and set aside;

[0049] (4): Weigh 40g of expanded vermiculite, 20g of sepiolite, and 30g of hollow microspheres prepared in step (1), step (2), and step (3) respectively, and mix them well to obtain Group A Minute;

[0050] (5): Add 120g of styrene-acrylic emulsion, 100g of water, 2g of wetting agent, 5g of dispersant, 4g of defoaming agent, 2g of silane coupling agent, and 5g of other additives in order, and mix evenly to obtain component B;

[0051] (6): Fully mix components A and B, stir at room temperature for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com