Large-power dye-sensitized solar cell

A technology for solar cells and dye sensitization, applied in the field of solar cells, can solve the problems of increasing the internal resistance of the battery, reducing the battery performance, and volatile organic solvents, and achieving the effects of improving performance, improving reliability and reducing transmission distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

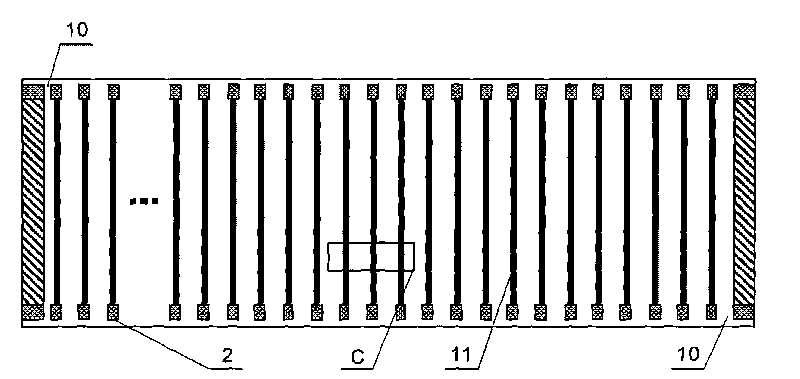

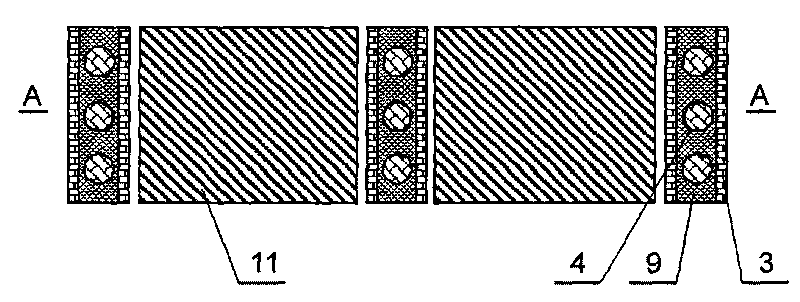

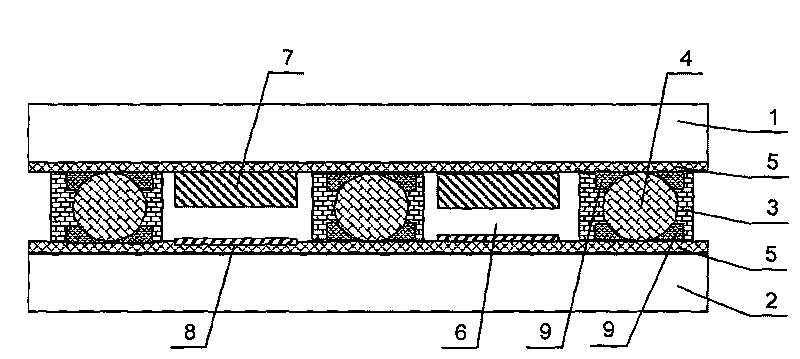

[0037] Glass Substrate Solar Cells

[0038] Preparation of TiO according to the process of making dye-sensitized monolithic solar cells 2 Colloidal solution and made into slurry, and prepare platinum counter electrode, silver glue and other screen printing paste, evenly mix the isolation material balls into low melting point glass powder to prepare the sealing paste, prepare to prepare TiO 2 Nanoporous film, platinum counter electrode, silver glue wire, glass powder wire. The positions of the thin film layers and electrodes are as follows: image 3 shown. Preparation process and steps: (1) The upper and lower substrates are made of transparent conductive TCO glass and cleaned, followed by ultrasonic cleaning with acetone, alcohol, and deionized water for 15 minutes, and then dried with pure nitrogen; (2) Silk screen Printing of various functional layers: including nano-TiO 2Thin film, platinum counter electrode layer, silver glue electrode, mixed glass powder line for isol...

Embodiment 2

[0040] Stainless Steel Substrate Solar Cell

[0041] Preparation of TiO according to the process of making dye-sensitized monolithic solar cells 2 Colloidal solution and paste, and prepare screen printing paste such as silver glue, ready to prepare TiO 2 nanoporous films. The positions of the thin film layers and electrodes are as follows: Figure 5 shown. Preparation process and steps: (1) The upper substrate is made of a transparent polymer plate (ITO-PET, ITO-PEN), the lower substrate is made of a stainless steel plate, and they are cleaned, followed by ultrasonic cleaning with acetone, alcohol, and deionized water for 15 minutes. (2) Sputter a layer of Pt counter electrode and Ag electrode on the transparent polymer substrate; (3) Spray glass spheres on the stainless steel substrate, and the glass spheres are evenly and sparsely distributed on the whole surface. (4) screen printing each functional layer, including nano-TiO 2 Thin film and silver glue electrodes are on...

Embodiment 3

[0043] Polymer Substrate Solar Cells

[0044] Preparation of TiO according to the process of making dye-sensitized monolithic solar cells 2 Colloidal solution and made into slurry, ready to prepare TiO 2 Nanoporous film; the positions of each film layer and electrodes are as follows Figure 5 shown. Preparation process and steps: (1) The upper and lower substrates are made of transparent polymer plates (ITO-PET, ITO-PEN) and cleaned, followed by ultrasonic cleaning with acetone, alcohol, and deionized water for 15 minutes, and then with pure (2) Sputter a layer of Pt counter electrode and Ag electrode on the transparent polymer substrate; (3) Spray glass balls on another transparent polymer substrate, and the glass balls are evenly and sparsely distributed on the whole (4) Deposit a layer of TiO on the substrate by embossing, screen printing, etc. 2 Thin film, sputtering Ag electrode; (5) drying or hydrothermal treatment, the sample is placed in a convection oven or a hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com