Preparation method of copper nanoparticles with different particle diameters

A technology of copper nanoparticles and particles, which is applied in the field of copper nanoparticles and its preparation, achieves the effects of low preparation requirements, controllable shape and particle size, and enhanced simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

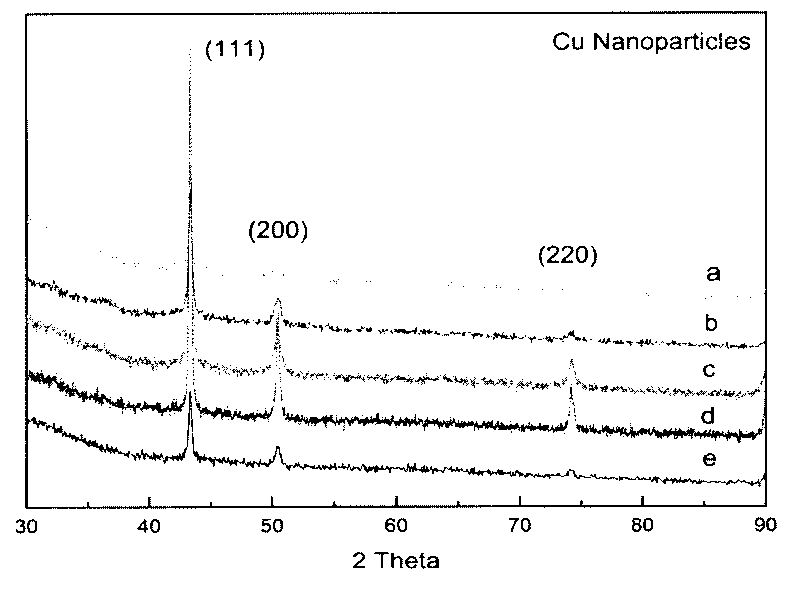

[0030] Example 1: Take 0.0025 mol of copper acetate and add it to 10 mL of ethylene glycol, take 1 mL of oleylamine and dissolve it in 10 mL of acetone, mix the two solutions, and stir vigorously. Disperse 0.25g of PVP in 8g of ethylene glycol (saturated sodium hydroxide), pour it into the mixture of the first two solutions, and heat to boiling. Disperse 1.00g of ascorbic acid in 12g of ethylene glycol (saturated with sodium hydroxide), then pour the ascorbic acid solution into the previous mixing system, the solution changes from blue to colorless quickly, then yellow, then red. Keep at the boiling point, continue to stir for 10min, and drop to room temperature. Extract the oil-soluble nanoparticles with cyclohexane, centrifuge them, take the precipitate, add acetone and alcohol mixture, ultrasonically disperse, and centrifuge at low speed for 5 minutes. The precipitate is copper nanoparticles with a particle size of 30-50nm, and take the upper cloudy liquid. The powder is s...

Embodiment 2

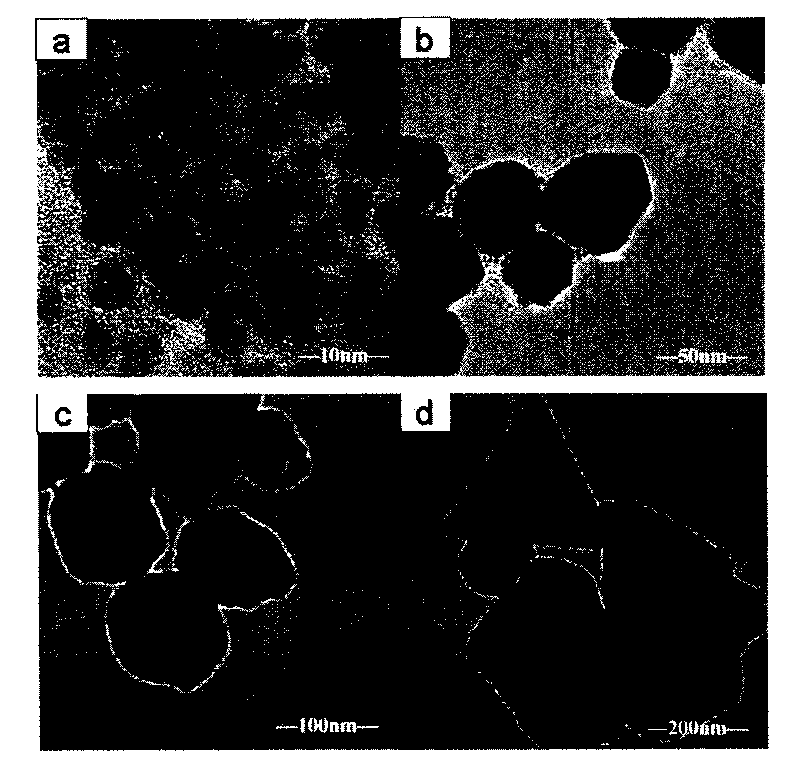

[0031] Example 2: 0.0025 mol of copper acetate was added to 10 mL of ethylene glycol, 1 mL of oleylamine was dissolved in 10 mL of acetone, and the two solutions were mixed and stirred vigorously. Disperse 0.2g of PVP in 8g of ethylene glycol (saturated with sodium hydroxide), pour it into the mixture of the first two solutions, and heat to boiling. Disperse 1.00g of ascorbic acid in 12g of ethylene glycol (saturated with sodium hydroxide), then pour the ascorbic acid solution into the previous mixing system, the solution changes from blue to colorless quickly, then yellow, then red. Keep at the boiling point, continue to stir for 10min, and drop to room temperature. Oil-soluble nanoparticles are extracted with cyclohexane, centrifuged, and the precipitate is taken, washed 3 to 5 times with acetone and alcohol, ultrasonically dispersed, and centrifuged at 6000 rpm for 5 minutes. The precipitate is copper nanoparticles with a particle size of 50nm (such as figure 2 shown in b...

Embodiment 3

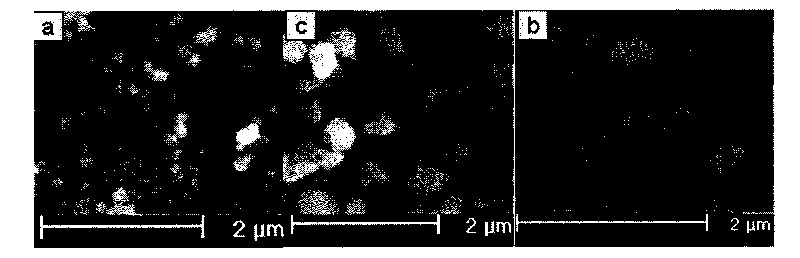

[0032]Example 3: Add 0.0025 mol of copper chloride and 6 mL of glycerin to 10 mL of ethylene glycol at the same time, dissolve 2 g of oleic acid in 10 mL of acetone, mix the two solutions, and stir vigorously. Disperse 1.5g of PVP in 8g of ethylene glycol, mix the two liquids, and heat to boiling. Disperse 1.00 g of ascorbic acid in 12 mL of ethylene glycol (saturated with sodium hydroxide), pour the ascorbic acid solution into the aforementioned system, and keep boiling for 40 min to obtain a red-yellow solution. Washing, centrifugation, obtains yellow powder, the spherical copper nanoparticle (such as the diameter 200nm) figure 2 c. figure 2 d. image 3 a and image 3 shown in b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com