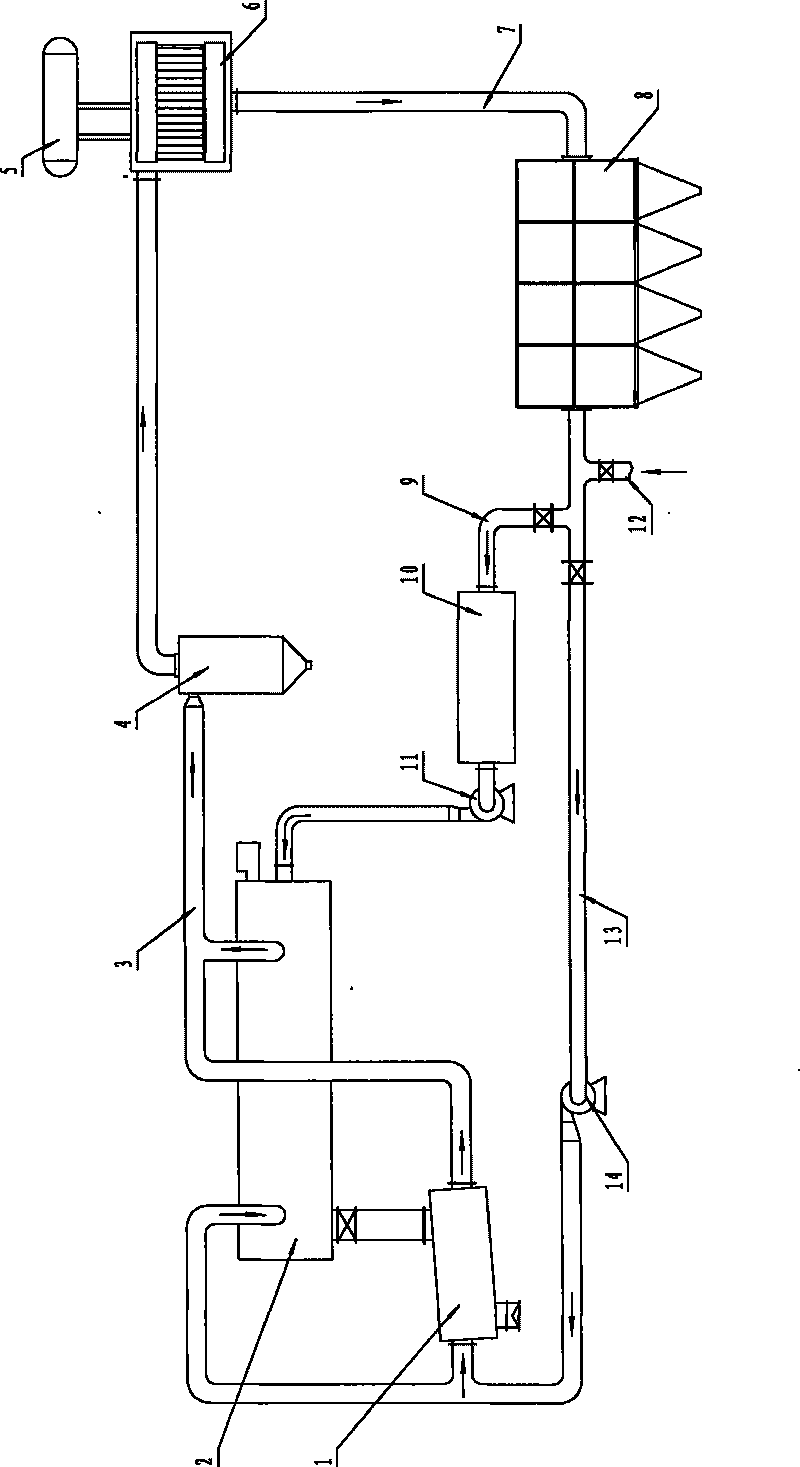

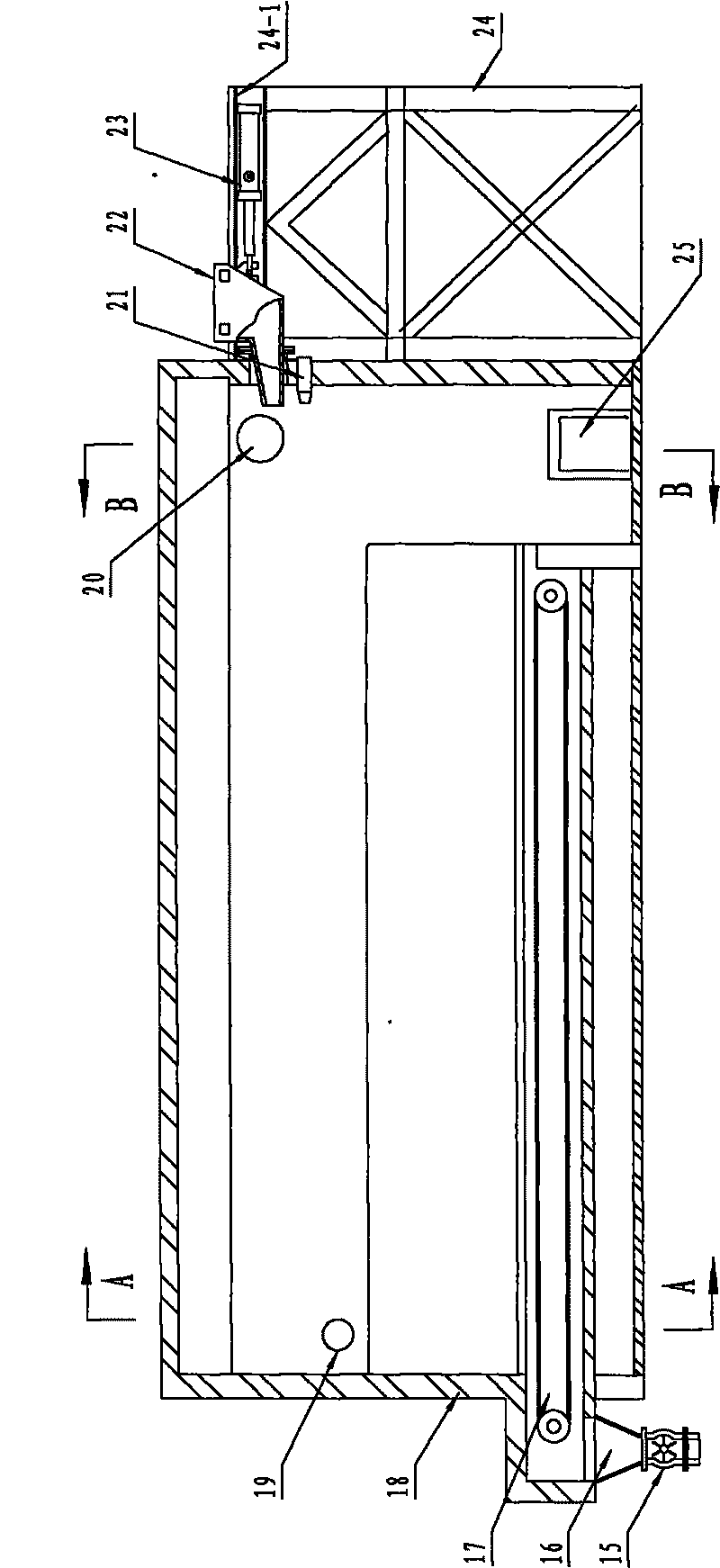

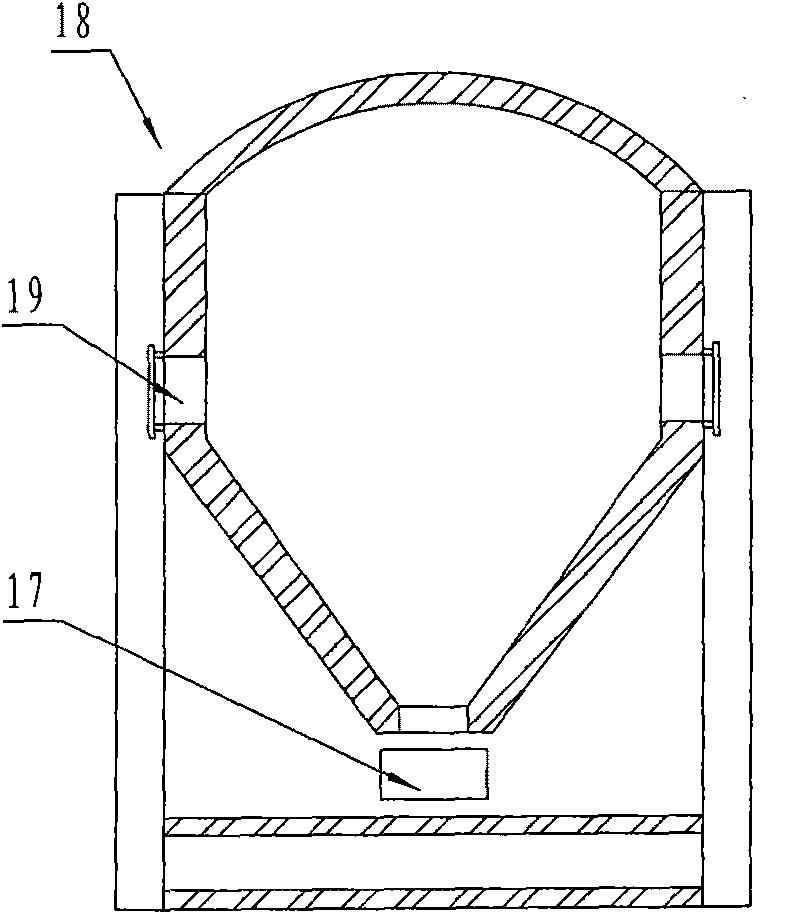

Process and device for processing liquid steel slag

A technology of liquid steel slag and processing technology, which is applied in the field of metallurgical production, can solve the problems of lack of industrial application technology, low sensible heat recovery rate of liquid slag, and failure to recycle, so as to achieve fine slag particles, reduce dust pollution, and facilitate the separation of slag and iron Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: The liquid steel slag treatment is carried out in the device of the present invention, the average flow rate of the liquid steel slag entering the granulation tank is 1t / min, the nitrogen pressure entering the gas quenching gas nozzle is 0.3Mpa, and the flow rate is 20Nm 3 / min, the cooling nitrogen pressure at the inlet of the granulation tank and the cooling tank is 6000Kpa, and the cooling nitrogen flow at the inlet of the granulation tank is 1200Nm 3 / min, cooling tank cooling nitrogen flow 1200Nm 3 / min. The temperature of the high-temperature cooling gas entering the waste heat boiler is 450°C.

Embodiment 2

[0041] Example 2: Liquid steel slag treatment is carried out in the device of the present invention, the average flow rate of liquid steel slag entering the granulation tank is 1t / min, the nitrogen pressure entering the gas quenching gas nozzle is 0.4Mpa, and the flow rate is 30Nm 3 / min, the cooling nitrogen pressure at the inlet of the granulation tank and the cooling tank is 5000Kpa, and the cooling nitrogen flow at the inlet of the granulation tank is 1100Nm 3 / min, cooling tank cooling nitrogen flow 1100Nm 3 / min. The temperature of the high temperature cooling gas entering the waste heat boiler is 500°C.

Embodiment 3

[0042] Example 3: The liquid steel slag treatment is carried out in the device of the present invention, the average flow rate of the liquid steel slag entering the granulation tank is 1t / min, the nitrogen pressure entering the gas quenching gas nozzle is 0.6Mpa, and the flow rate is 40Nm 3 / min, the cooling nitrogen pressure at the inlet of the granulation tank and the cooling tank is 4000Kpa, and the cooling nitrogen flow at the inlet of the granulation tank is 1000Nm 3 / min, cooling tank cooling nitrogen flow 1000Nm 3 / min. The temperature of the high temperature cooling gas entering the waste heat boiler is 550°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com