Synthetic bamboo and wood vinegar, and production method and applications thereof

A technology of bamboo and wood vinegar and edible water, applied in botany equipment and methods, medical preparations containing active ingredients, applications, etc., can solve problems such as unstable content, harmful to human body and environment, and difficult to remove

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

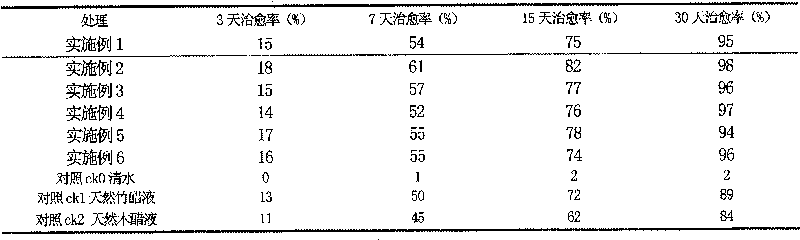

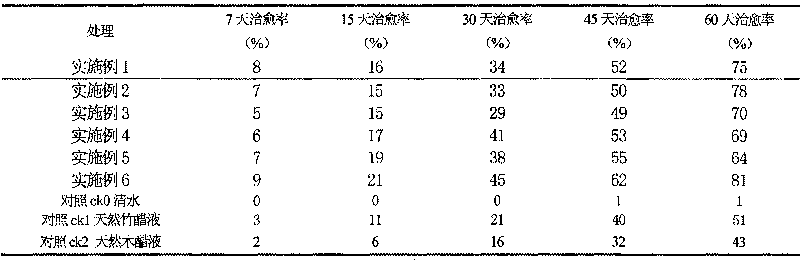

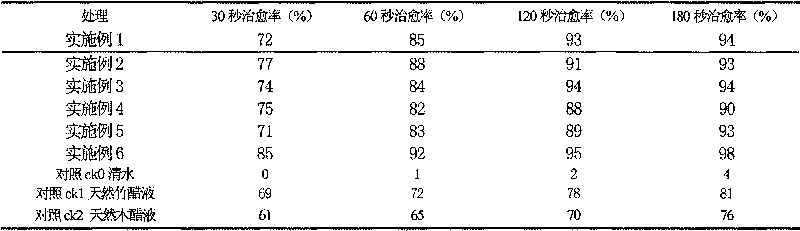

Examples

Embodiment 1

[0020] Put 901kg of pure water into the 1000L reactor, gradually add 80kg of acetic acid, slowly add 8kg of ethanol and 8kg of ethylene glycol under constant stirring, then add 2kg of isoorientin, stir and dissolve until evenly mixed, then slowly add 2kg of spice FE9071307 , after stirring and dissolving, it becomes the final product.

Embodiment 2

[0022] Put 965kg of tap water into the 1000L reactor, slowly add 30kg of propionic acid under constant stirring, slowly add 1kg of ethanol and 1kg of ethylene glycol under constant stirring, then add 2kg of orientin, stir and dissolve until evenly mixed, then slowly add 1kg of spice HY540805, stirred and dissolved to become the final product.

Embodiment 3

[0024] Put 930kg of mineral water into the 1000L reaction kettle, slowly add 60kg of acetic acid, 7.4kg of glycerol, and then add 1.7kg of vitexin, stir and dissolve until uniformly mixed, heat to 80°C, and then slowly add 7.4kg The polyvinyl alcohol 124, stirred and dissolved, cooled naturally to room temperature, then added 0.3kg HY540102, 0.3kg HY541303 and 0.3kg HY540307, stirred and dissolved to form the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com