Submerged-entry nozzle centring device

一种注入口、浸入式的技术,应用在金属加工设备、铸造设备、铸造熔融物容器等方向,能够解决损毁设备、增大工人安全事故、钢坯爆裂等问题,达到确保操作安全性、提高制造效率、提高质量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

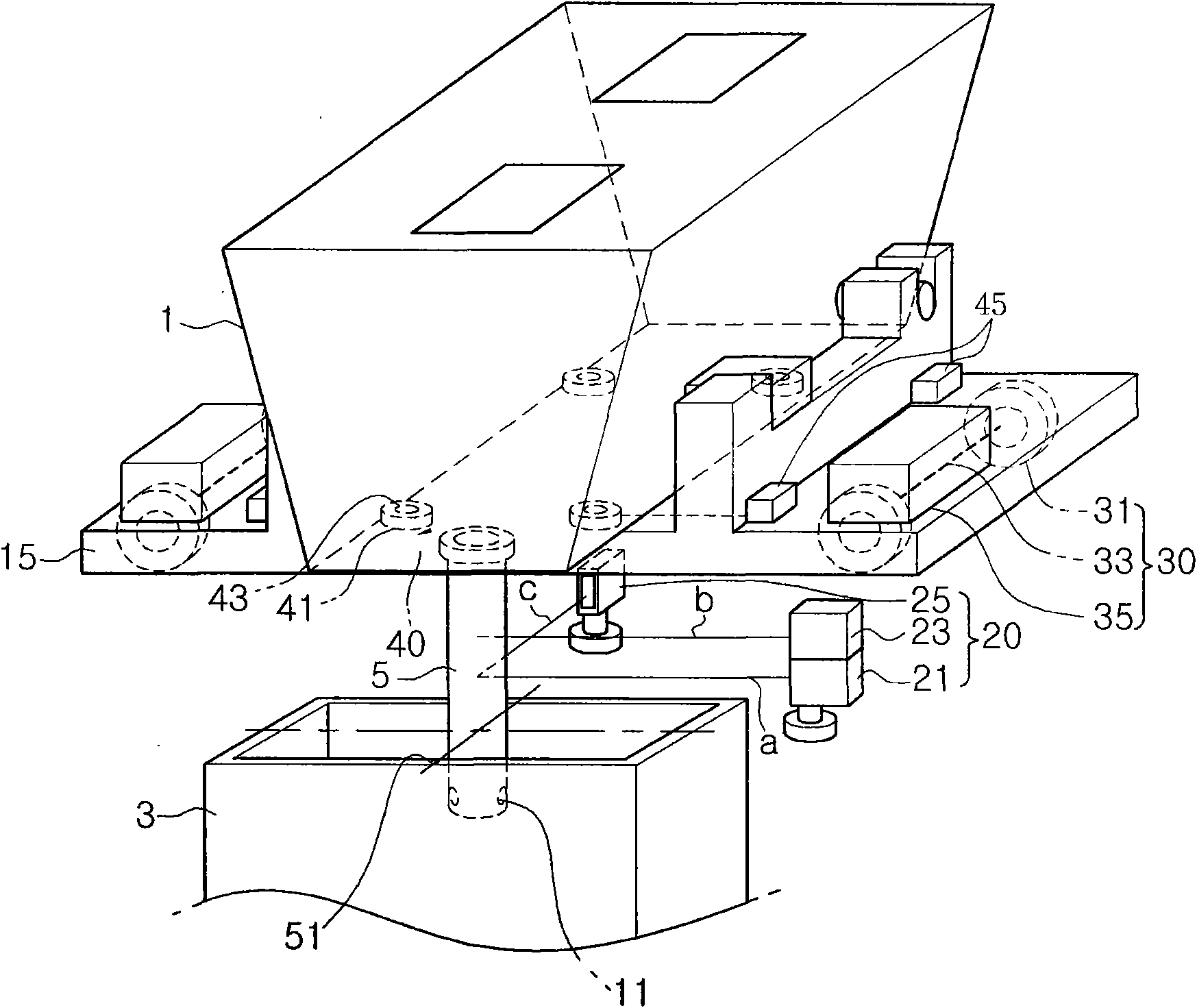

[0032] A preferred embodiment of the device for centering the submerged sprue according to the present invention will be described in detail below with reference to the accompanying drawings.

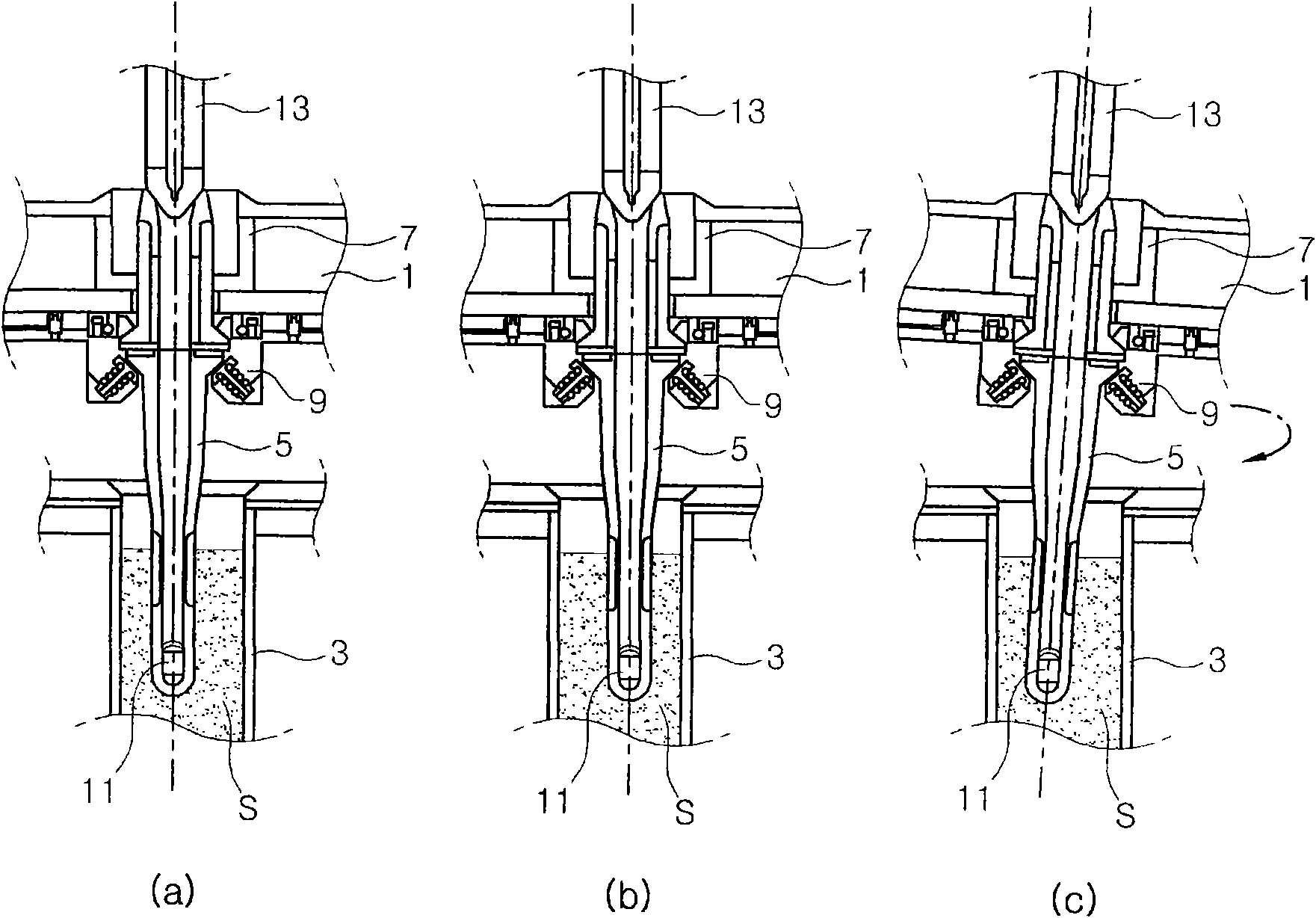

[0033] image 3 is a perspective view showing the construction of a preferred embodiment of the apparatus for centering a submerged sprue according to the present invention. The same structure as the prior art consists of figure 1 indicated by the reference numerals shown in .

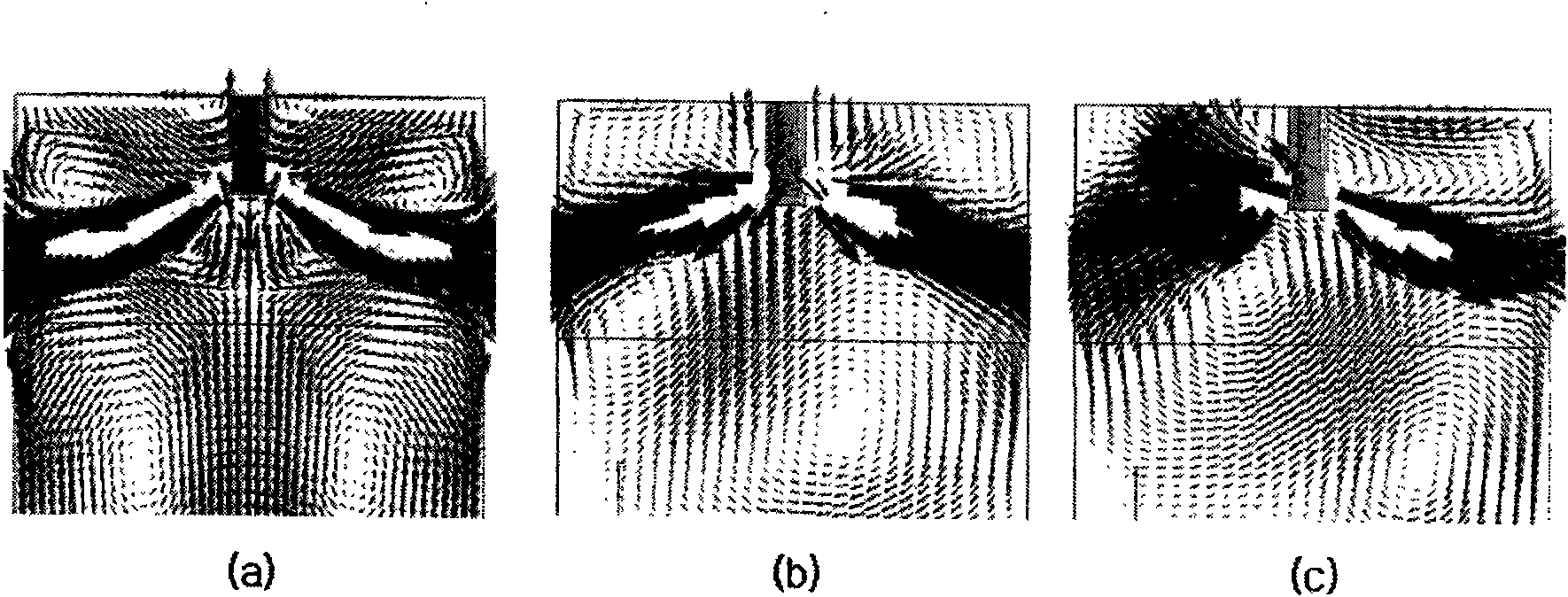

[0034] Before describing this embodiment below, it should be noted that the submerged sprue 5 is connected with the lower part of the tundish 1 through the sprue connector 9, and is inserted into the crystallizer 3 arranged below the tundish 1, so that the molten steel Inject from tundish 1 into crystallizer 3 . In addition, two molten steel outflow holes 11 are oppositely formed at the lower part of the submerged sprue 5 so as to supply the molten steel in the tundish 1 into the mold 3, centering the submerg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com