Autoclaved phosphogypsum brick and method for preparing same

A technology of gypsum bricks and phosphogypsum, which is applied in the field of autoclaved phosphogypsum bricks and its preparation, can solve the problems of low strength, low cost, and high strength of phosphogypsum bricks, and achieve the effects of low manufacturing cost, increased strength, and low quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The autoclaved phosphogypsum brick provided in this embodiment is made from the following raw materials:

[0034]60kg of phosphogypsum, 7.8kg of calcium carbide slag, 30kg of zinc smelting slag, 2kg of construction sand with a particle size of <2mm, 0.2kg of Glauber’s salt, and 15kg of water.

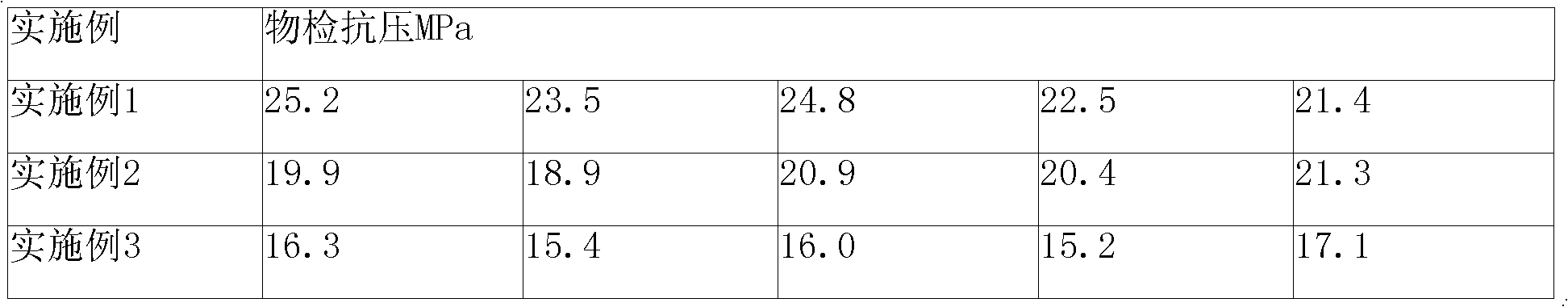

[0035] The raw materials in the above ratio are prepared into autoclaved phosphogypsum bricks according to the steps of material preparation, batching, grinding, stirring, brick making and curing. Choose 5 autoclaved phosphogypsum bricks prepared in this example, according to the standard of GB / T 2542-2003 "Test Method for Wall-laying Bricks", carry out compression test with TYE-3000 pressure testing machine, the results are shown in Table 1.

Embodiment 2

[0037] The autoclaved phosphogypsum brick provided in this embodiment is made from the following raw materials:

[0038] Phosphogypsum 75kg, calcium carbide slag 3.9kg, fluidized furnace coal slag 20kg, construction sand with particle size <2mm 1kg, Glauber’s salt 0.1kg, water 11kg.

[0039] The raw materials in the above ratio are prepared into autoclaved phosphogypsum bricks according to the steps of material preparation, batching, grinding, stirring, brick making and curing. Choose 5 autoclaved phosphogypsum bricks prepared in this example, according to the standard of GB / T 2542-2003 "Test Method for Wall-laying Bricks", carry out compression test with TYE-3000 pressure testing machine, the results are shown in Table 1.

Embodiment 3

[0041] The autoclaved phosphogypsum brick provided in this embodiment is made from the following raw materials:

[0042] 80kg of gypsum, 3.9kg of lime slag, 15kg of chain grate furnace coal slag, 1kg of construction sand with a particle size of <2mm, 0.1kg of sodium sulfate, and 10kg of water.

[0043] The raw materials in the above ratio are prepared into autoclaved phosphogypsum bricks according to the steps of material preparation, batching, grinding, stirring, brick making and curing. Choose 5 autoclaved phosphogypsum bricks prepared in this example, according to the standard of GB / T 2542-2003 "Test Method for Wall-laying Bricks", carry out compression test with TYE-3000 pressure testing machine, the results are shown in Table 1.

[0044] Table 1 Compression test results of phosphogypsum unburned bricks

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com