Halogen-less high frequency resin composition, and prepreg and laminate manufacturing by using same

一种树脂组合物、预浸料的技术,应用在合成树脂层状产品、织物、涂层等方向,能够解决磷系阻燃剂易吸水、水敏感、材料吸水率大等问题,达到优异耐热性、低吸水率、低介电常数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention relates to a halogen-free flame-retardant resin composition, which contains, in parts by weight of organic solids:

[0018] (A) Styrene-maleic anhydride oligomer, 10-50 parts by weight;

[0019] (B) At least one compound having a dihydrobenzoxazine ring, 10-50 parts by weight;

[0020] (C) At least one polyepoxy compound, 10-50 parts by weight;

[0021] (D) Phosphorus-containing flame retardant, 5-30 parts by weight.

[0022] The components are described in detail below.

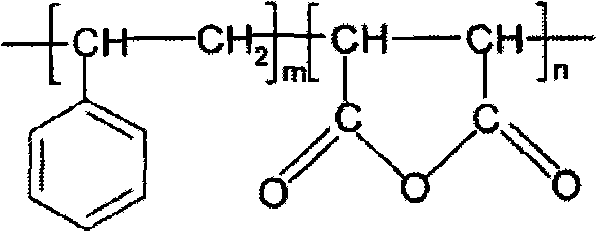

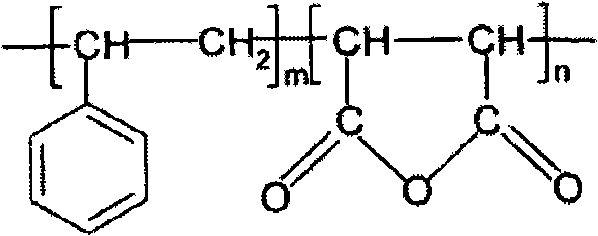

[0023] The component (A) described in the present invention is a styrene-maleic anhydride (SMA) oligomer, which can further improve the thermal and electrical properties of polymers and products. The selected SMA has a molecular weight of 1400 to 50,000. The recommended SMA oligomer content range is 1400-14400. Such as the commercially available SMA1000, SMA2000, SMA EF-30, EF-40, EF-60 and EF-80. The SMA can be used alone or in combination, and the recommended dosage is 10-50 parts by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com