Environment-friendly process for producing dihydromyrcenol by using dihydromyrcene hydration reaction

A technology of dihydromyrcenol and dihydromyrcene, which is applied in the field of green technology, can solve the problems of low conversion rate and long reaction time, and achieves the effects of improving conversion rate, saving energy and equipment investment, and facilitating continuous operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

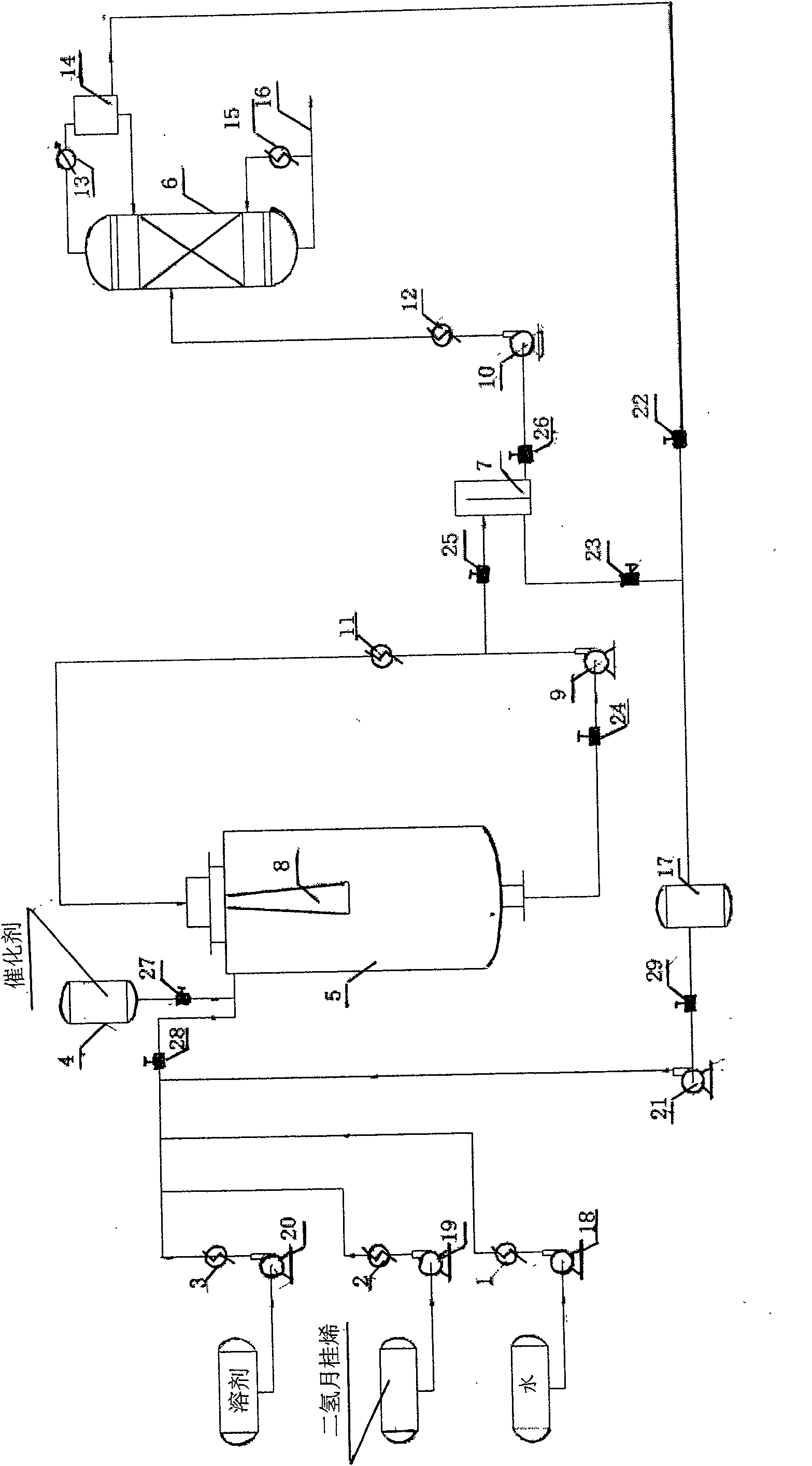

[0021] Dihydromyrcene, water and alcohol solvents (ethanol, propanol or butanol) are in a mass ratio of 1:1:1, preheated by preheaters 1, 2 and 3 respectively to reach a reaction temperature of 105°C and a pressure of 0.2 MPa (gauge pressure), and open the valve 27, with 10% sulfuric acid solution (addition is based on 100% H 2 SO 4 Calculated as accounting for 1% of the total material including solvent,) mixed into the jet reactor 5. The reaction material in the jet reactor 5 enters the ejector 8 in the jet reactor 5 through the outlet at the bottom of the jet reactor 5 through the centrifugal pump 9 and the heat exchanger 11 (the ejector is provided by Shuanghong Engineering Technology Development Co., Ltd. Provided, the same below.), sprayed into the jet reactor 5, and reacted. After the reaction was carried out for 3 hours, the valve 25 was opened, the jet reactor 5 began to discharge, and the reaction feed liquid entered the oil-water separator 7. Simultaneously, the r...

Embodiment 2

[0024] Similar to the operation process of Example 1, dihydromyrcene, water and acetone solvent are in a mass ratio of 1: 1: 2, respectively preheated through preheaters 1, 2 and 3 to reach a reaction temperature of 115 ° C, and a pressure of 0.5 MPa ( Gauge pressure), and open the valve 27, with 15% phosphoric acid solution (addition amount is based on 100% H 3 PO 4 Calculated as accounting for 1.2% of the total material including the solvent) mixed into the jet reactor 5. Other operating steps are the same as in Example 1. The conversion rate of dihydromyrcene in the process is over 98%, and the selectivity is over 92%.

Embodiment 3

[0026] Similar to the operation process of Example 1, dihydromyrcene, water and dioxane solvent are in a mass ratio of 1: 2: 2, and are preheated by preheaters 1, 2 and 3 respectively to reach a reaction temperature of 100° C. and a pressure of 0.1MPa (gauge pressure), and open valve 27, enter in jet reactor 5 after mixing with 15% p-toluenesulfonic acid (accounting for 100% p-toluenesulfonic acid is accounted for 15% including the total material of solvent). Other operating steps are the same as in Example 1. The conversion rate of dihydromyrcene in the process is over 90%, and the selectivity is over 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com