M-c-n-o fluorescent substance

An M-C-N-O, phosphor technology, applied in the field of inorganic electroluminescent elements, light-emitting elements or fluorescent tubes, can solve the problems of high crystallinity of BN particles, low oxygen content, low crystallinity (low hexagonal crystallinity, etc.) Efficiency, effect of changing hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0128] The preparation method of the transparent electrode layer can adopt vapor phase methods such as sputtering and vacuum deposition. Paste ITO and tin oxide can be produced by coating or screen printing. In addition, it is also possible to form a film by a thermal method such as spray pyrolysis. In this case, the higher the heat resistance of the transparent film, the more preferable.

[0129] (middle layer)

[0130] The dispersion-type EL element may have at least one intermediate layer between the transparent electrode layer and the emitter layer and / or the rear electrode and the dielectric layer. The middle layer can be organic polymer compound or inorganic compound or compound them. The thickness of the intermediate layer is preferably not less than 10 nm and not more than 10 μm, more preferably not less than 100 nm and not more than 1 μm.

[0131] In the case where the material forming the intermediate layer is an organic polymer compound, usable polymer compounds...

Embodiment 1

[0160] Get 1.53g (0.025mol) boric acid (H 3 BO 3 ) and 15.3g (0.25mol) of urea ((NH 2 ) 2 CO) into a 300ml beaker, add 33.3g of ultrapure water, stir with a hot stirrer (rotational speed: 500rpm), and dissolve. Then, 0.5 g of PEG (molecular weight: 20,000) manufactured by Wako Co., Ltd. was added, and stirred again at a rotation speed of 500 rpm with a heating stirrer. The obtained raw material solution was transferred to a crucible, and fired at 800° C. for 30 minutes at a heating rate of 20° C. / minute in a heating furnace.

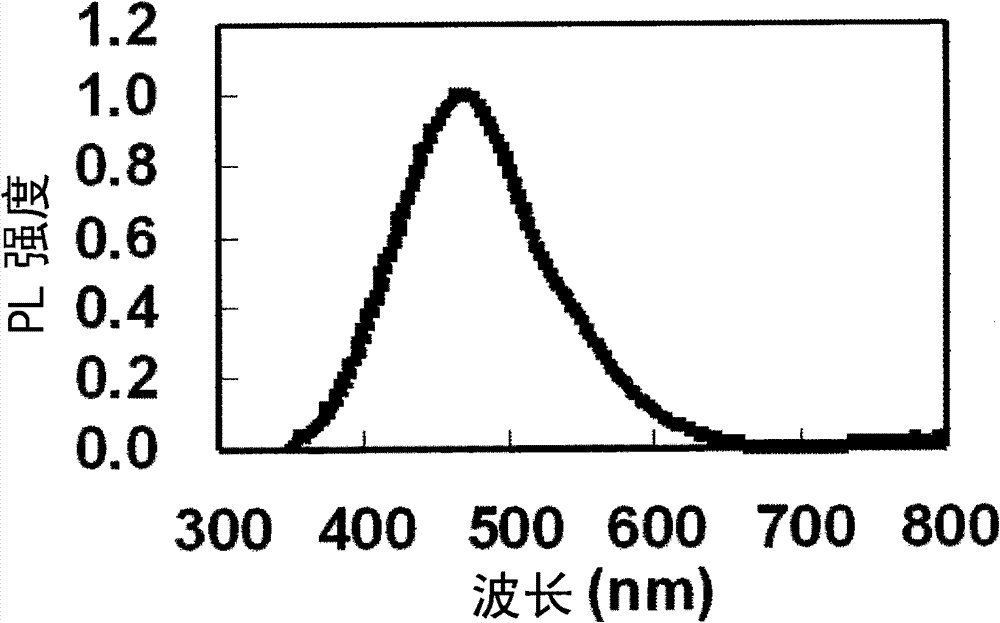

[0161] figure 1 The ultraviolet excitation emission spectrum results of the phosphor obtained in Example 1 are shown. exist figure 1 , the horizontal axis represents wavelength, and the vertical axis represents PL intensity (luminescence (Photoluminescence: PL) intensity). The same applies to the following drawings.

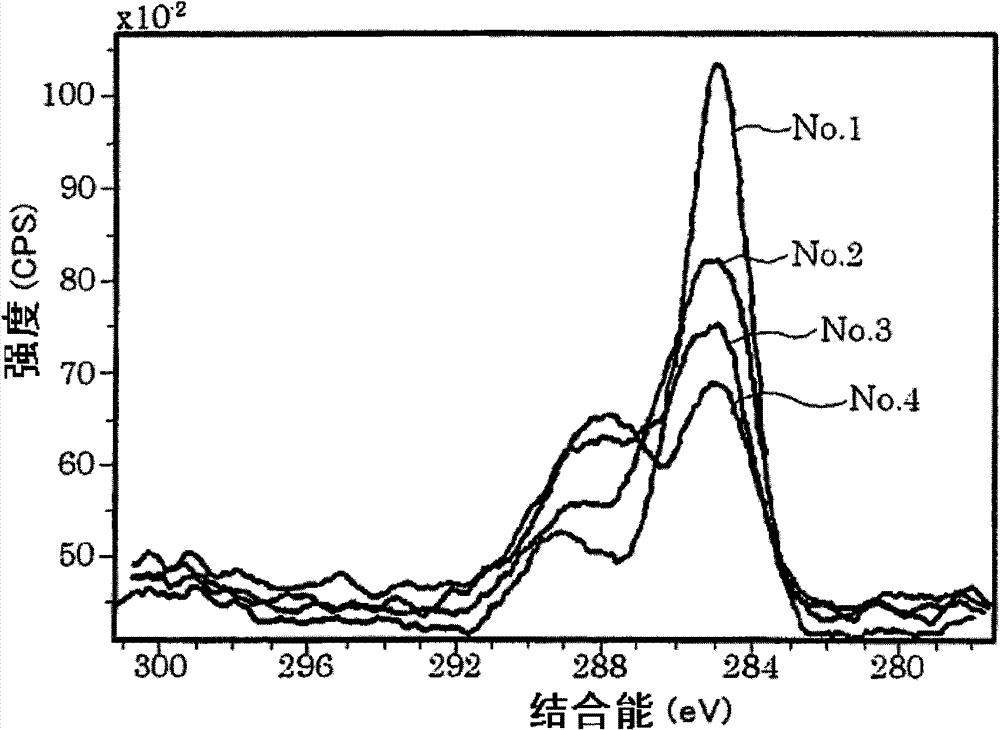

[0162] figure 2 (No. 1) shows the XPS measurement results of the phosphor obtained in Example 1. From this result, it can be ...

Embodiment 2

[0165] Except that the firing temperature in Example 1 was 900 degreeC, it carried out similarly to Example 1. The content of each element is shown in Table 1, and the peak of the emission wavelength is shown in Table 2. The XPS measurement results of the phosphors are in figure 2 (No.2) shown. The results of ultraviolet excitation luminescence spectroscopy in image 3 shown in .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com