Magnetic field generating tool for active water, and fluid treating device using the tool

一种流体处理、活性水的技术,应用在磁场/电场水/污水处理、水/污水处理、水/污水处理设备等方向,能够解决操作性欠缺、磁性化的水活性度不匀、保养有欠缺等问题,达到稳定性优异、组装操作性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

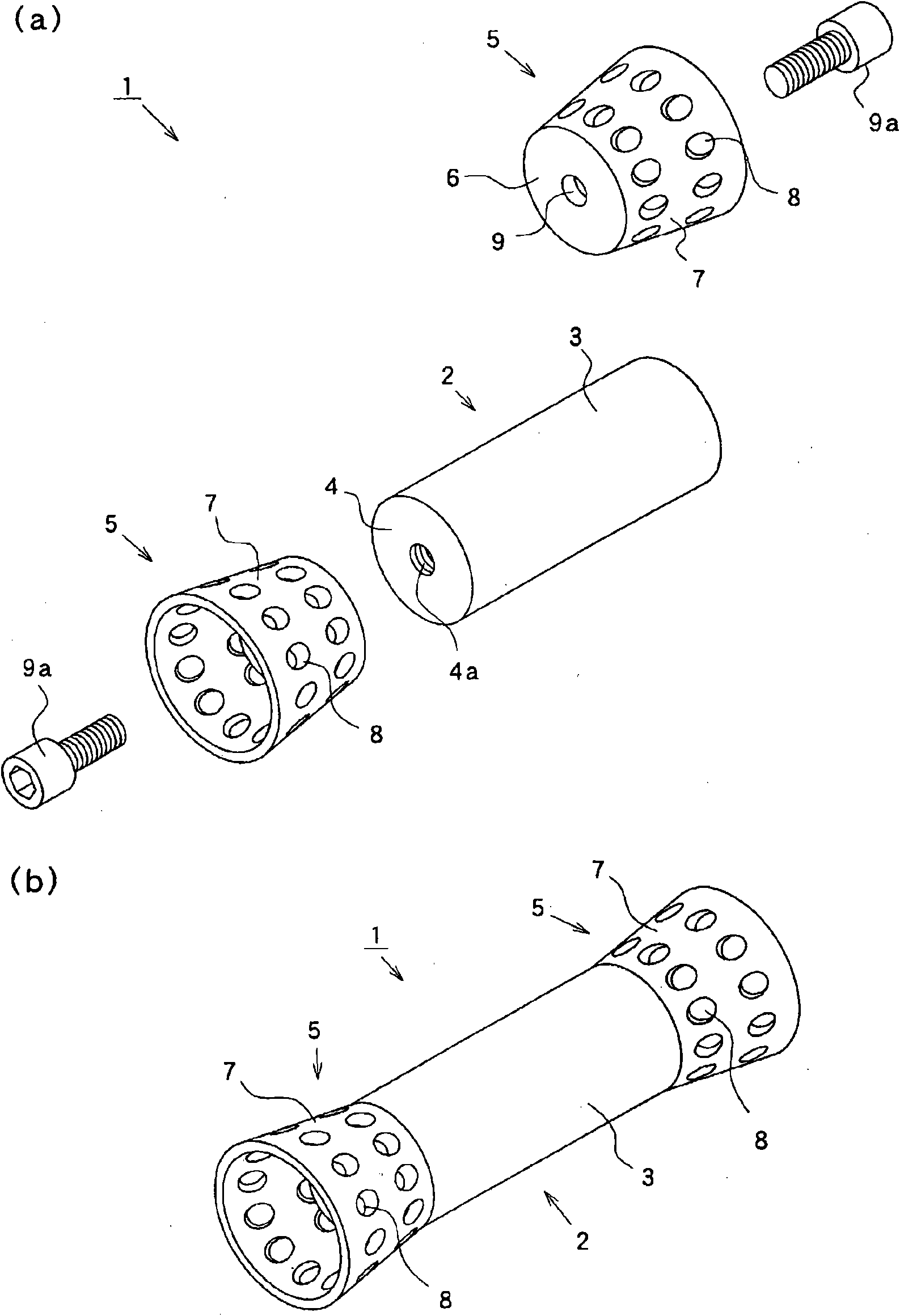

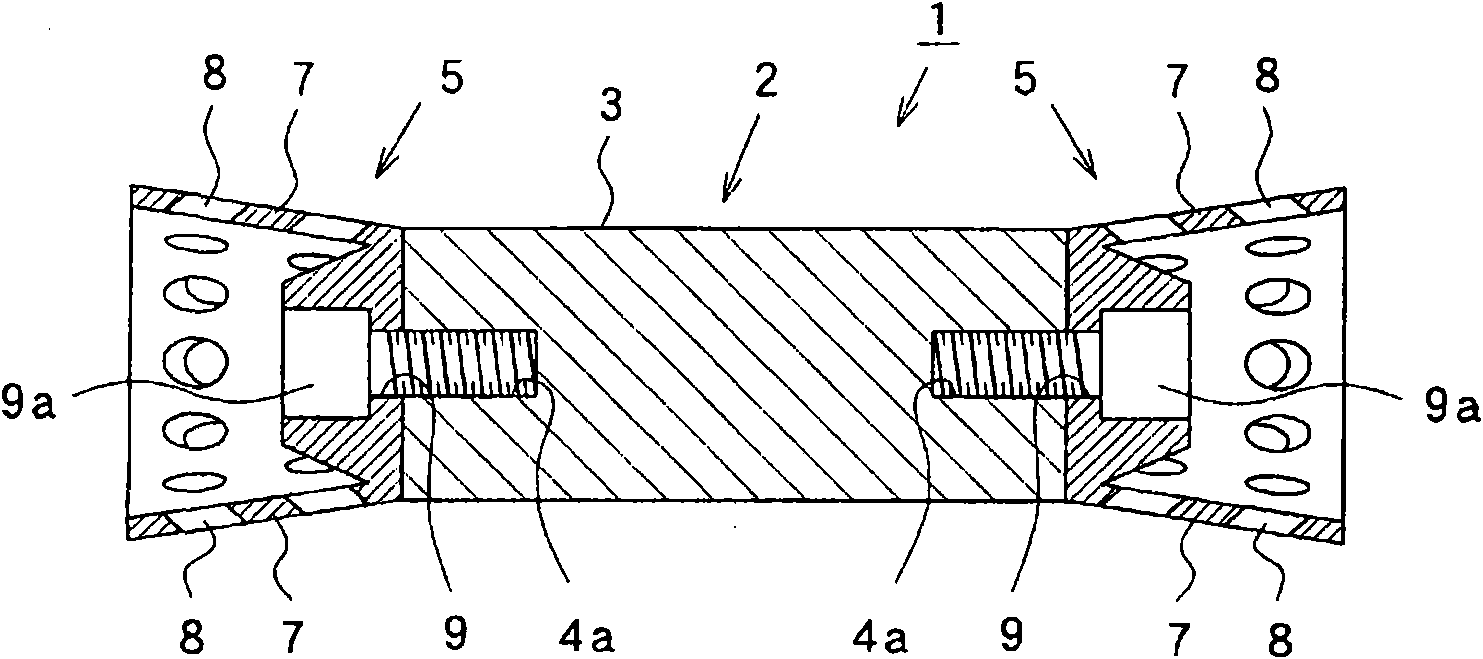

[0142] figure 1 (a) is an exploded perspective view of the magnetic field forming device for active water according to Embodiment 1 of the present invention, (b) is a perspective view of the magnetic field forming device for active water, figure 2 It is a sectional view of the main part of the magnetic field forming device for active water.

[0143] figure 1 , figure 2 Among them, 1 is the magnetic field forming device for active water according to Embodiment 1 of the present invention, 2 is a magnet formed into a round bar shape by using a rare earth cobalt magnet, etc., 3 is a side surface of the magnet 2, 4 is an end face of the magnet 2, and 4a is a magnet on the surface of the magnet 2. The bolt hole portion formed by the end face 4 of the steel pipe is made of non-magnetic materials such as aluminum alloy, copper alloy, titanium alloy, nickel-chromium-iron heat-resistant and corrosion-resistant alloy (Inconel), stainless steel, high manganese steel, synthetic resin, ...

Embodiment approach 2

[0175] Figure 8 It is a perspective view of the magnetic field forming device for active water of Embodiment 2, Figure 9 (a) is a perspective view seen from the slope part side of the guide member of the magnetic field forming tool for active water of the modification of Embodiment 2, (b) is a perspective view seen from the base part side. In addition, the same parts as those described in Embodiment 1 are denoted by the same reference numerals, and description thereof will be omitted.

[0176] Figure 8 Among them, 1a is the active water magnetic field forming device of Embodiment 2 of the present invention, 2 is a magnet, and 3 is the side of the magnet 2, and 5a is made of aluminum alloy, copper alloy, titanium alloy, nickel-chromium-iron heat-resistant and corrosion-resistant alloy, The guide member formed of non-magnetic materials such as stainless steel, high manganese steel, synthetic resin, inorganic material, etc., 6a is a base part formed in a cylindrical shape an...

Embodiment approach 3

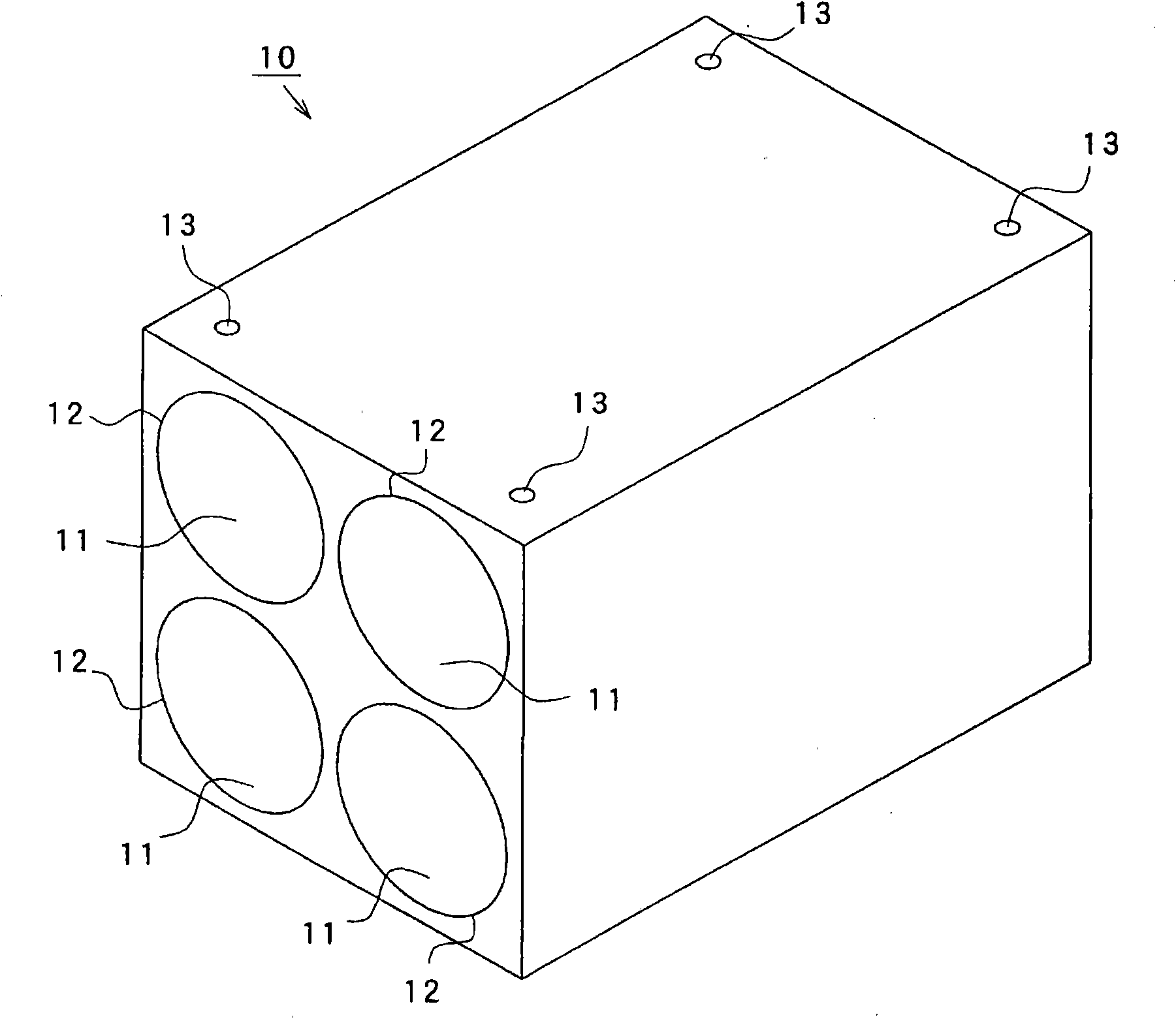

[0183] Figure 10 is a sectional view of main parts of a fluid processing device according to Embodiment 3 of the present invention, Figure 11It is a cross-sectional view of main parts of a modified example of the fluid processing device of the third embodiment. In addition, the same parts as those described in Embodiment 1 are denoted by the same reference numerals, and description thereof will be omitted.

[0184] Figure 10 Among them, 41 is the fluid processing device of Embodiment 3, and 42 is formed of light-weight and less-corroded materials such as titanium alloy, nickel-chromium-iron heat-resistant and corrosion-resistant alloy, stainless steel, high-manganese steel, synthetic resin, and inorganic materials. Opened rectangular parallelepiped bottomed box-shaped, and the processing chamber of the fluid processing device 41 with two casings 10 containing four magnets 2 placed side by side at the bottom, 43 is placed on the casings 10, 10 placed side by side 44 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com