Missile-borne thermal battery activation device

A technology for activating device and thermal battery, applied in primary battery, primary battery use/maintenance, circuit, etc., can solve the problems of large space occupied by the firing mechanism, heavy weight, and large pulling force, etc. Low cost and simple assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

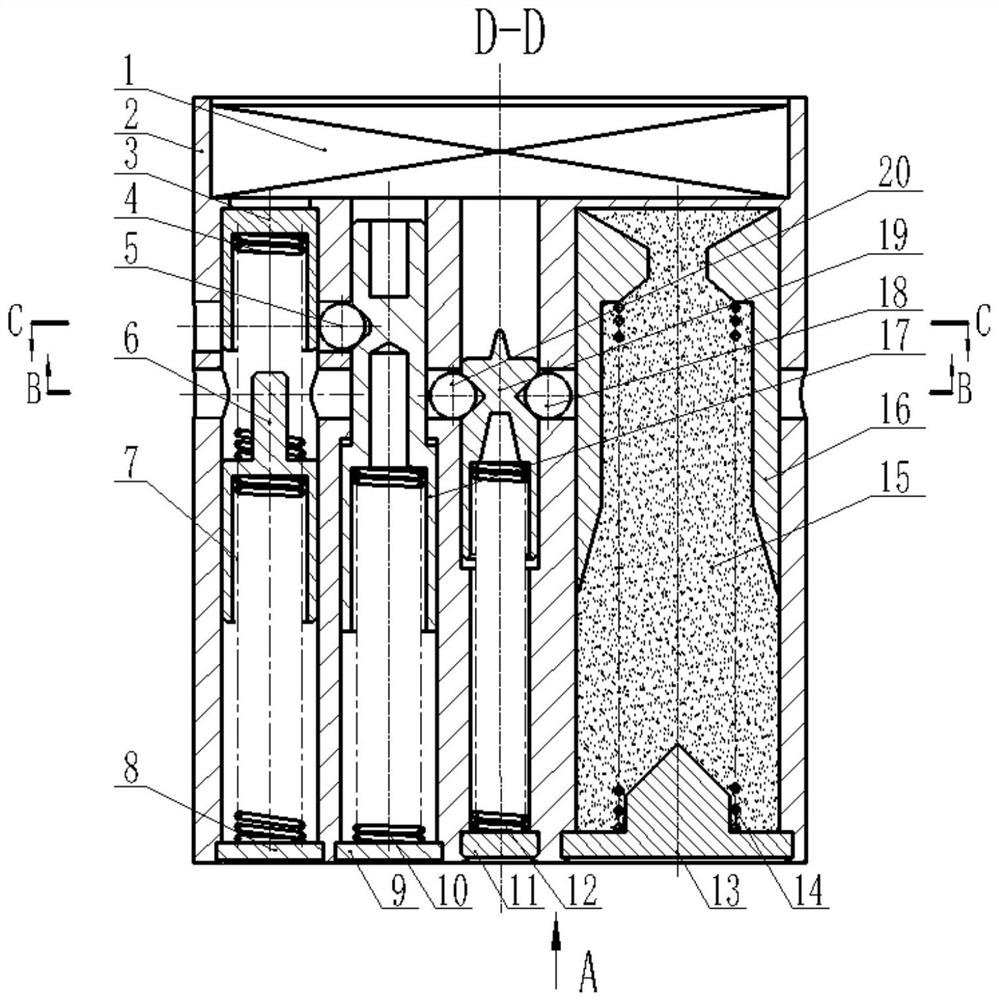

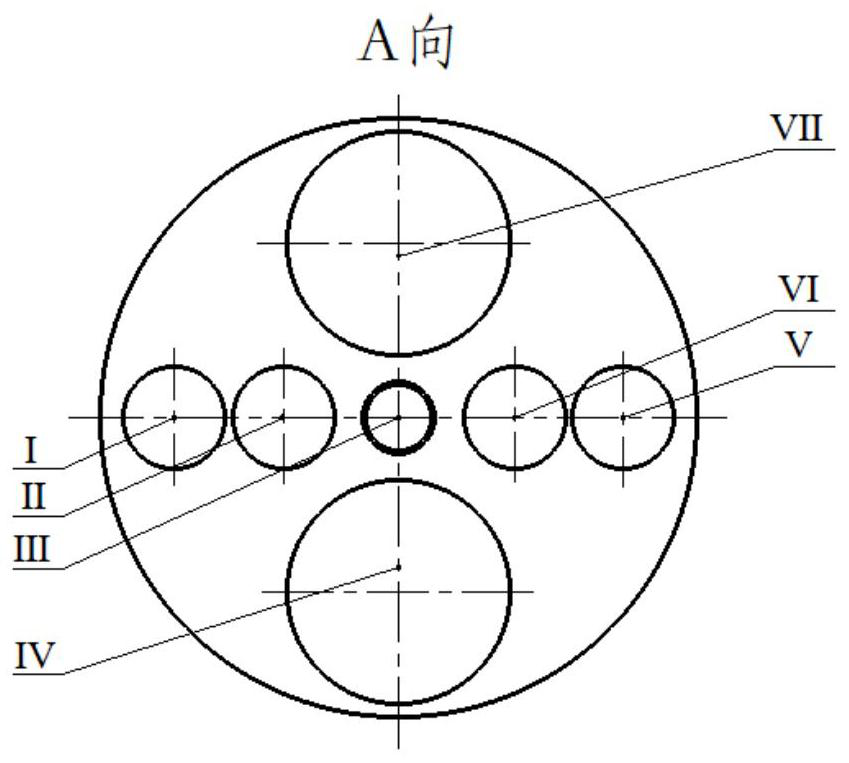

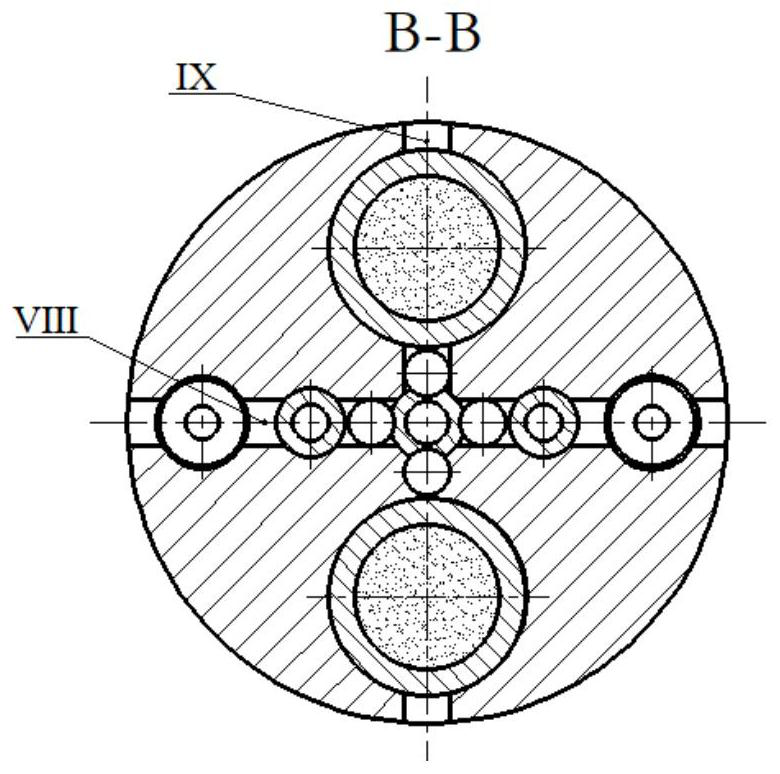

[0017] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

[0018] combine Figure 1-Figure 4 , a bomb-borne heat battery activation device of the present invention, its safety mechanism is two sets of two sets of parallel connection, respectively, a two-degree-of-freedom recoil safety mechanism and a quasi-fluid recoil safety mechanism, specifically including a heat battery 1, a body 2, and a firing mechanism , Two sets of dual-degree-of-freedom recoil safety mechanisms and two sets of quasi-fluid recoil safety mechanisms;

[0019] The firing mechanism includes a plug 11, a firing pin spring 12; a firing pin 19;

[0020] The two-degree-of-freedom recoil safety mechanism includes an upper inertia cylinder 3, an upper inertia spring 4, a safety ball I5, a lower inertia cylinder 6, a lower inertia spring 7, a bottom cover 8; a blocking block 9, an inertia pin spring 10, and an inertia pin 17;

[0021] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com