Glass fiber reinforced plastic cable channel cover plate and production method thereof

A cable trench cover, glass fiber technology, used in artificial islands, underwater structures, buildings, etc., can solve the problems of poor impact resistance, inconvenient to move, rough surface of the cover, and achieve good insulation performance and Fire retardant performance, ensure safe operation, regular and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

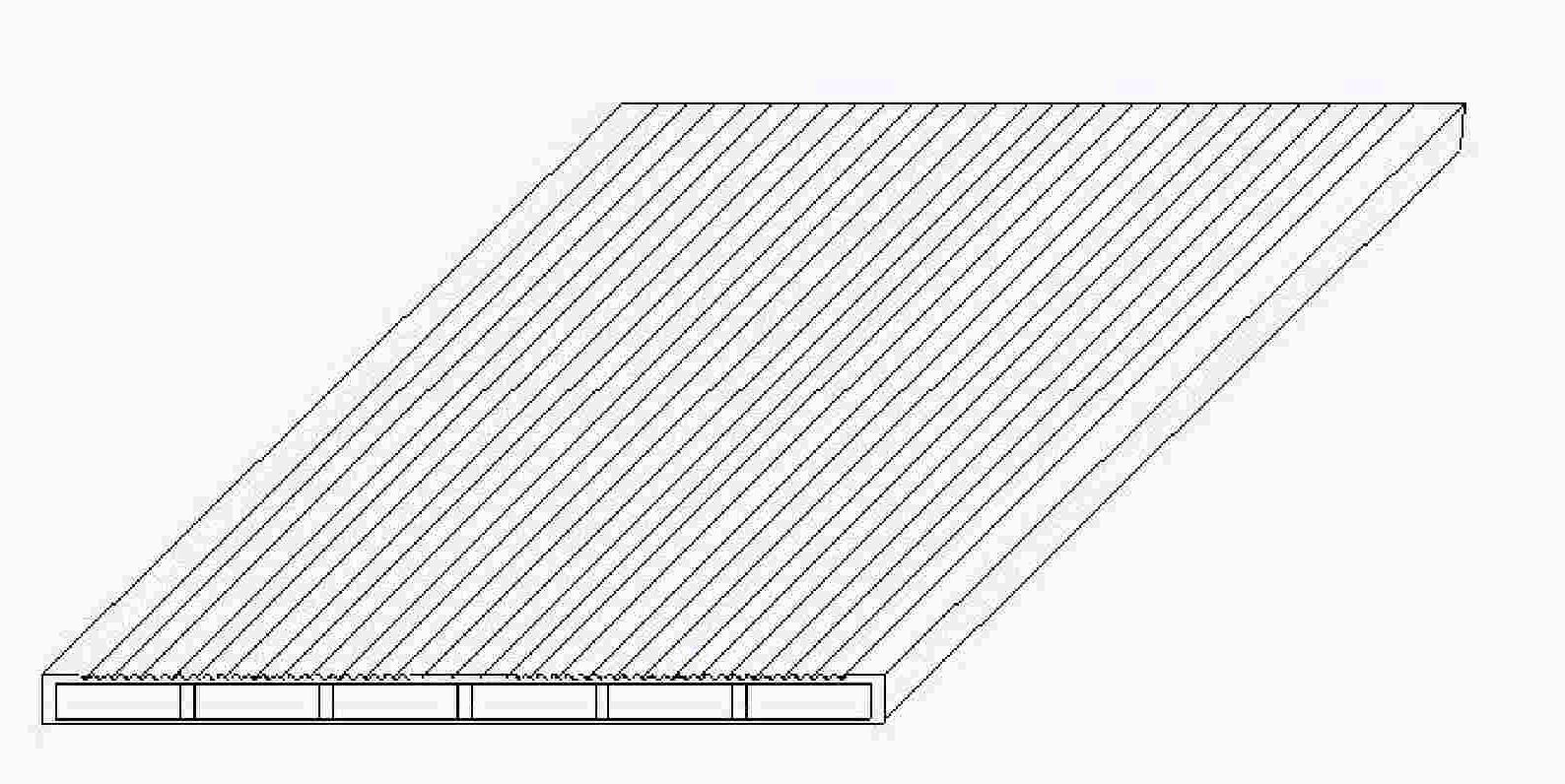

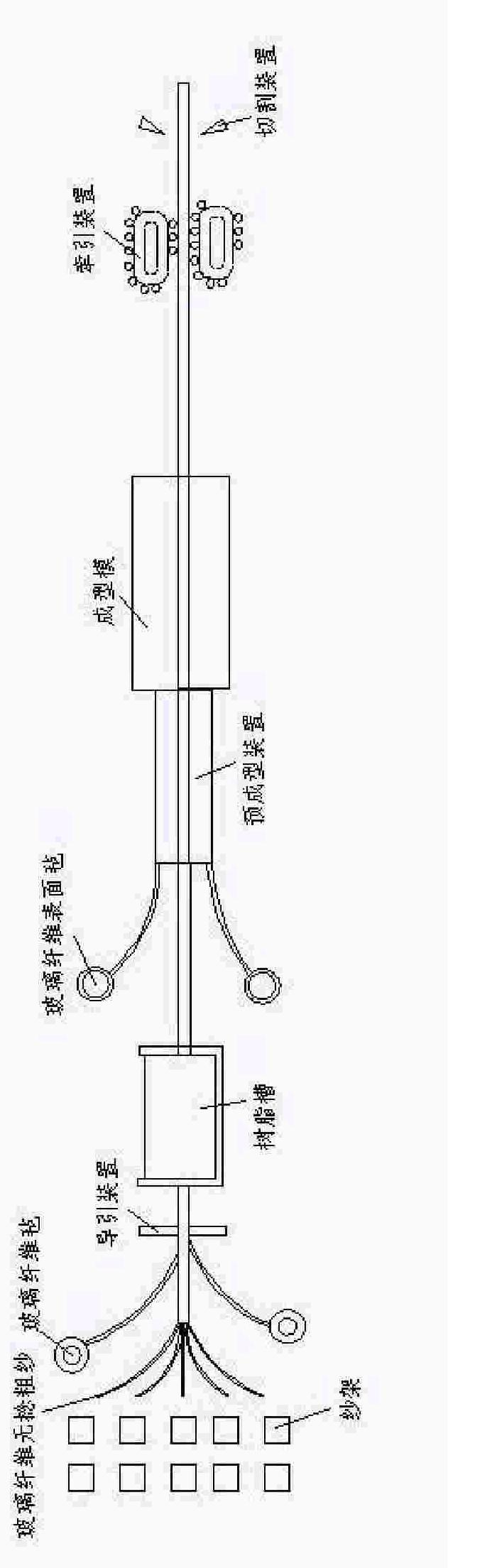

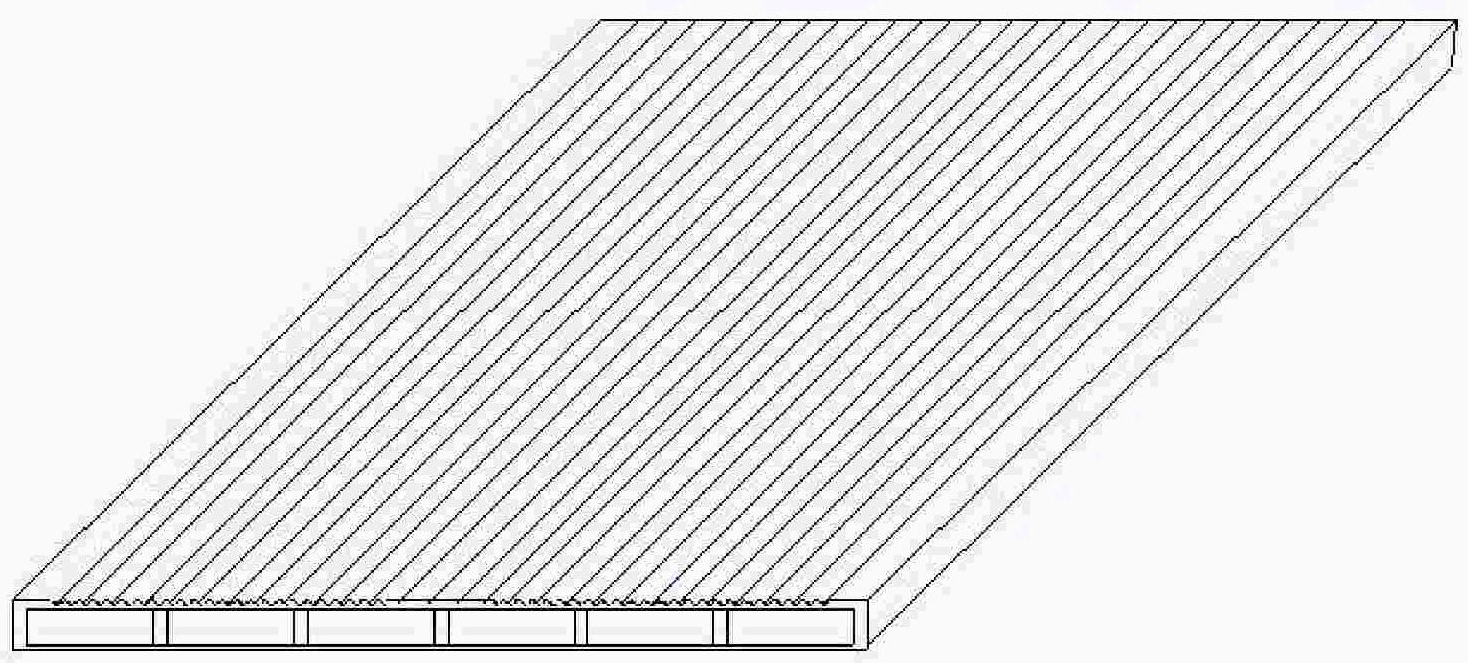

[0024] see figure 1 with figure 2 , a production method of a black-gray glass fiber reinforced plastic cable trench cover, which is completed by the following raw materials and process steps:

[0025] The weight proportion of each raw material is:

[0026] Unsaturated polyester resin 29%

[0027] Dibenzoyl Peroxide 1%

[0028] tert-Butylperoxyneodecanoate 1%

[0029] Ground calcium carbonate powder 6%

[0030] Aluminum hydroxide powder 4%

[0031] Carbon black 0.3%

[0032] Polyvinyl alcohol solution 1%

[0033] E-glass fiber roving 50%

[0034] E-glass fiber continuous mat 6%

[0035] E-glass fiber surface mat 1.7%

[0036] The steps are:

[0037] (1) Setting of tooling equipment: Creel, guiding device, resin tank, preforming device, forming mold, traction device and cutting machine are arranged in sequence on the extrusion molding machine production line;

[0038] (2) Ingredients: put the unsaturated polyester resin, curing agent, filler, polyvinyl alcohol solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com