Preparation method of titanium alloy micro-arc oxide coating

A micro-arc oxidation and titanium alloy technology, applied in the field of preparation of oxide coatings, can solve the problems affecting the use of titanium alloys and the easy fracture of the oxide film, and achieve the effects of high surface hardness, good wear resistance and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

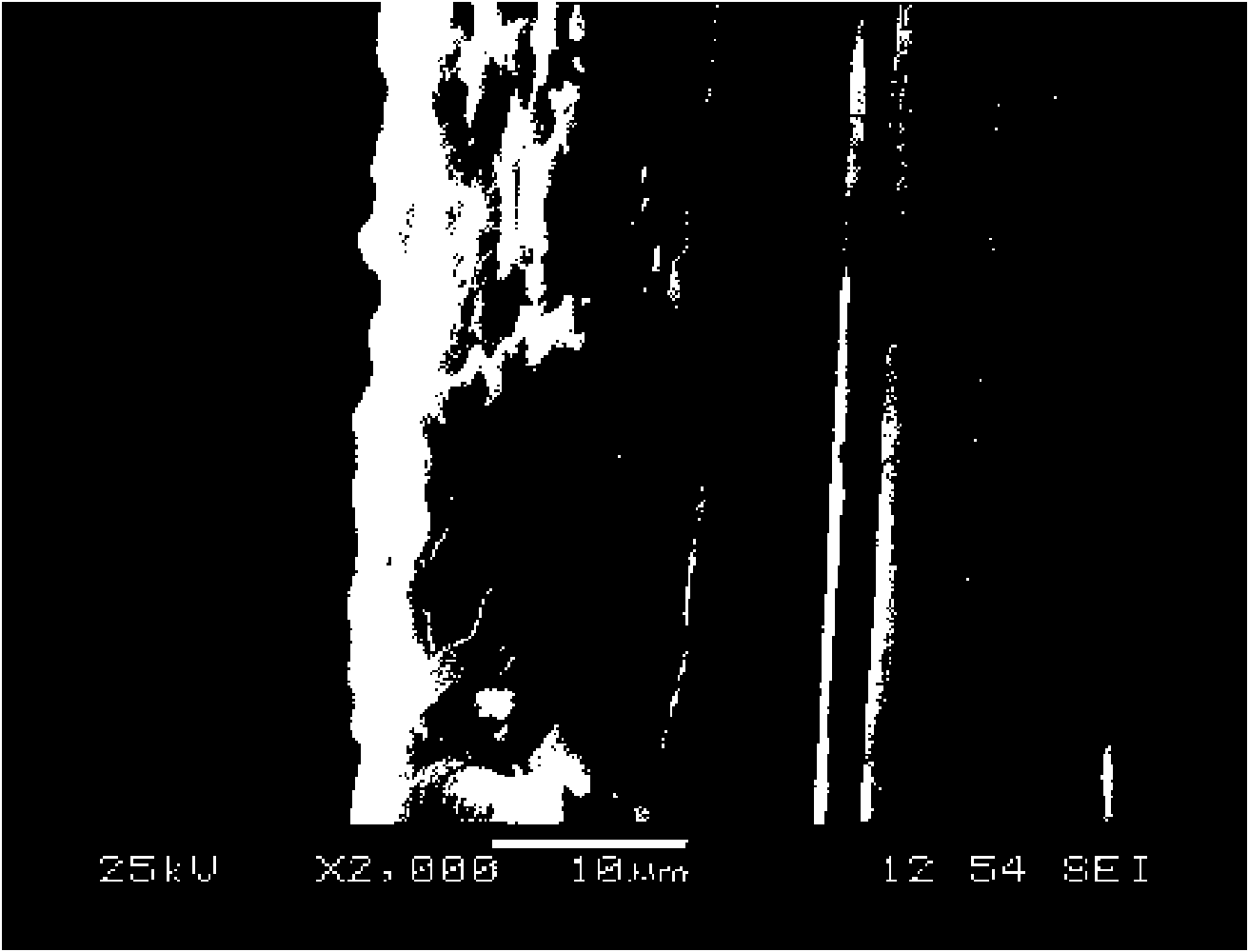

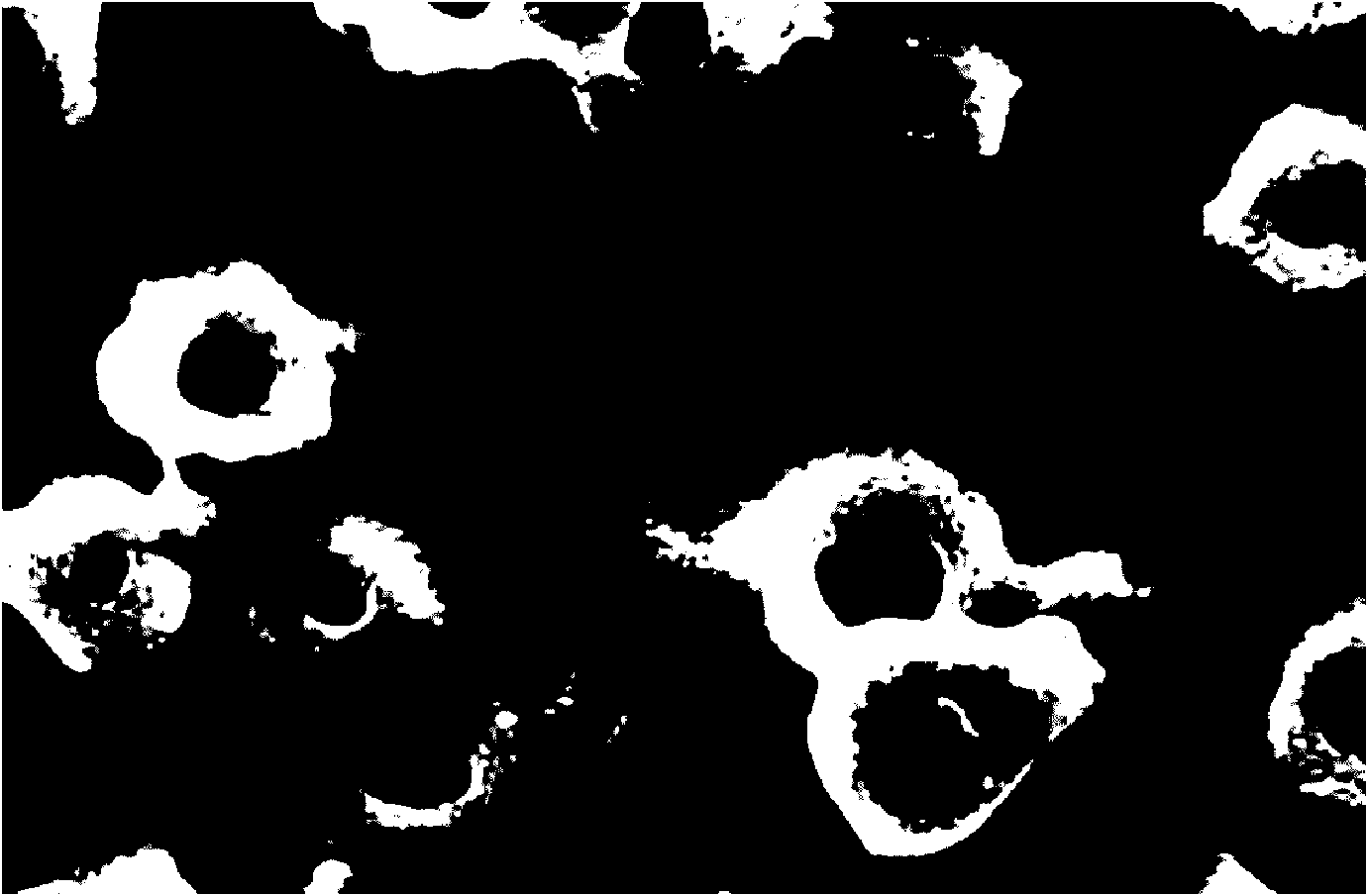

specific Embodiment approach 1

[0009] Specific Embodiment 1: The preparation method of the titanium alloy micro-arc oxidation coating in this embodiment is as follows: the titanium alloy is subjected to a bipolar pulse micro-arc oxidation power supply with a power of 5kw-6kw, a voltage of 250V-400V, and a frequency of 200Hz-400Hz , Oxidation treatment in the electrolyte solution for 5 minutes to 30 minutes under the condition of a duty ratio of 8% to 15%, to obtain a titanium alloy with a micro-arc oxidation coating thickness of 3 μm to 15 μm; wherein the electrolyte solution is composed of sodium silicate, Composed of sodium phosphate, sodium fluoride, sodium borate, glycerin and water, the concentration of sodium silicate in the electrolyte solution is 10 g / L-20 g / L, the concentration of sodium phosphate is 10 g / L-20 g / L, fluorine The concentration of sodium chloride is 2 grams / liter to 5 grams / liter, the concentration of sodium borate is 2 grams / liter to 5 grams / liter, and the concentration of glycerin is...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the electrolyte solution is composed of sodium silicate, sodium aluminate, sodium fluoride, sodium borate, glycerin and water, and the concentration of sodium silicate in the electrolyte solution is 10 g / L-20 g / L, the concentration of sodium aluminate is 10 g / L-15 g / L, the concentration of sodium fluoride is 2 g / L-5 g / L, and the concentration of sodium borate is 2 g / L liter to 5 g / liter, and the concentration of glycerin is 5 milliliters / liter to 10 milliliters / liter. Others are the same as in the first embodiment.

[0014] The bipolar pulsed micro-arc oxidation power supply used in this embodiment is a WHD10-400 type bipolar pulsed micro-arc oxidation power supply. The positive DC output current / voltage of the bipolar pulsed micro-arc oxidation power supply is up to 500A / 800V, The highest output current / voltage to DC is 500A / 300V, and the power is 5kW.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the voltage is 280V-380V. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com