Preparation method for three-dimensional ordered macroporous chelating resin

A three-dimensional ordered, chelating resin technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of difficult post-functionalization and cumbersome preparation methods, and achieve small diffusion resistance, good hydrophilicity, and selectivity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

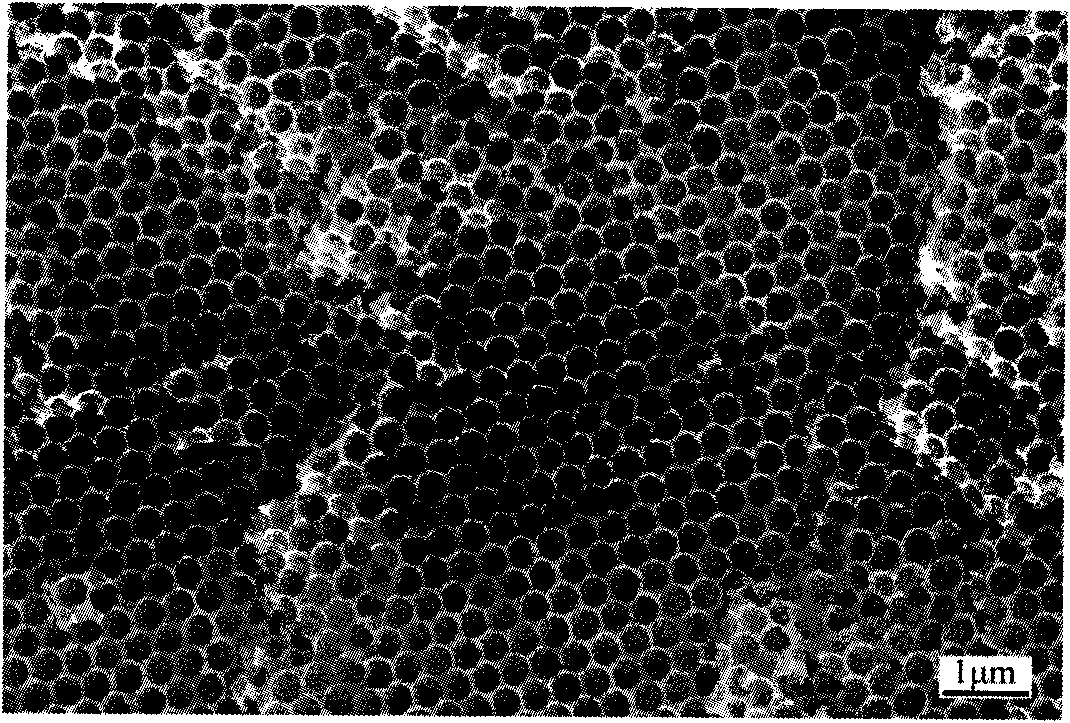

[0044] Preparation of Novel Three-Dimensional Ordered Macroporous Chelating Resin Containing 2-Mercaptobenzothiazole with Average Pore Size of 180nm

[0045] (a) Preparation of silica template

[0046] At room temperature, add 12.0g of absolute ethanol, 6.2g of 25% ammonia water and 10.0g of distilled water in sequence in a three-neck flask equipped with electric stirring. After stirring evenly, quickly add 14.2g of ethyl orthosilicate, and react 8 After one hour, pour the obtained suspension into a 500mL beaker, and the solvent evaporates naturally at room temperature, and then sinters the template in a muffle furnace at 200°C for 2 hours, and slowly lowers to room temperature to obtain carbon dioxide with an average particle size of 180nm. Silica colloidal crystal template.

[0047] (b) Preparation of three-dimensional ordered macroporous materials:

[0048] Add 0.5g block-shaped colloidal crystal template with the average particle size of 200nm silica microspheres adhered...

Embodiment 2

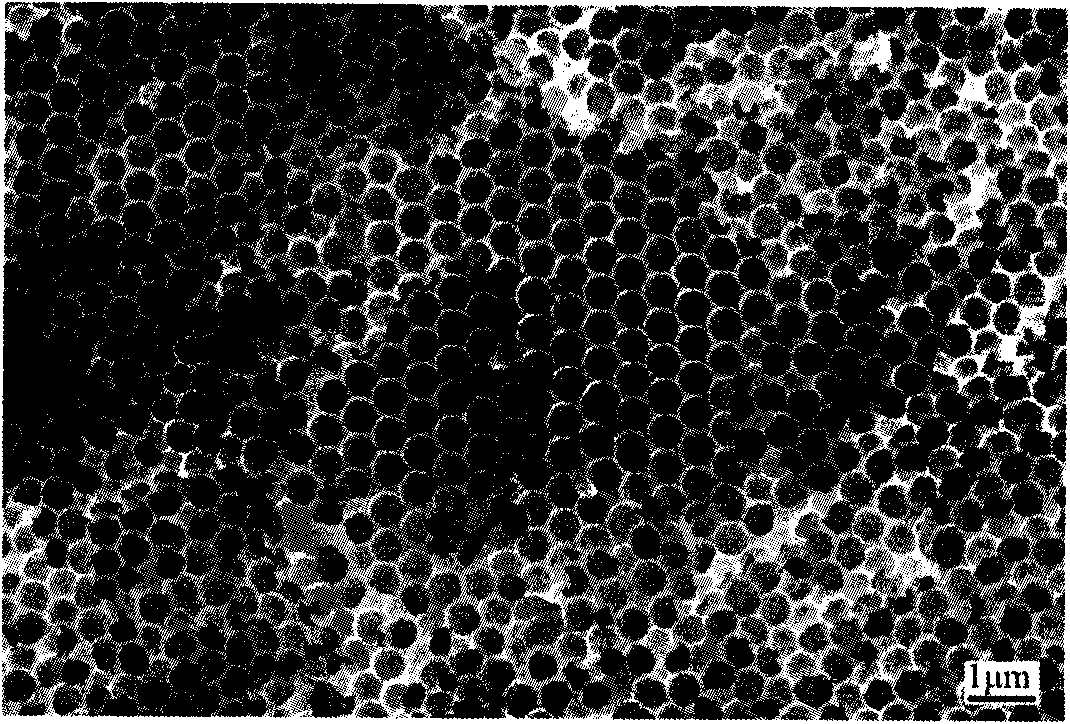

[0061] Preparation of a new three-dimensional ordered macroporous chelating resin containing 4-aminopyridine with an average pore size of 340nm.

[0062] (a) The preparation steps of the silica template refer to step (a) of Example 1, and only adjust the amount of reagents added: 13.8 g of absolute ethanol, 7.5 g of ammonia water with a percentage concentration of 25%, 13.5 g of distilled water, and ethyl orthosilicate 12.8g to obtain a silica template with an average particle size of 400nm.

[0063] (b) The preparation method of the three-dimensional ordered macroporous cross-linked polystyrene material is the same as the step (b) of Example 1, changing the initiator to 0.0055g dibenzoyl peroxide, prepolymerizing at 55°C for 2 hours, 80°C After reacting for 12 hours, a three-dimensional ordered macroporous cross-linked polystyrene with a pore diameter of 340 nm was obtained.

[0064](c) The chloromethylation method of three-dimensional ordered macroporous cross-linked polyst...

Embodiment 3

[0070] Preparation of Chelating Resin Containing 4-Amino-Triazole with Average Pore Diameter of 460nm

[0071] (a) The preparation of the silica template refers to the step (a) of Example 1, except that the addition of reagents is changed to 13.8 g of dehydrated alcohol, 7.5 g of ammonia water with a percentage concentration of 25%, 12.5 g of distilled water, and ethyl orthosilicate. 13.8g. A silica template with an average particle diameter of 500 nm was obtained.

[0072] (b) The preparation method of the three-dimensional ordered macroporous cross-linked polystyrene is the same as the step (b) of Example 1, except that the initiator is 0.0164g tert-butyl peroxybenzoate, which is pre-polymerized at 60°C for 4 hours, at 80°C After reacting for 10 hours, a three-dimensional ordered macroporous cross-linked polystyrene with a pore diameter of 460 nm was obtained.

[0073] (c) The chloromethylation method of three-dimensional ordered macroporous cross-linked polystyrene is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com