Laser helper roll bending formation device and method thereof

A laser-assisted, roll-bending technology, used in laser welding equipment, other manufacturing equipment/tools, welding equipment, etc., can solve problems such as reducing production costs, reducing molding passes, work hardening, etc. The effect of reduced times and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

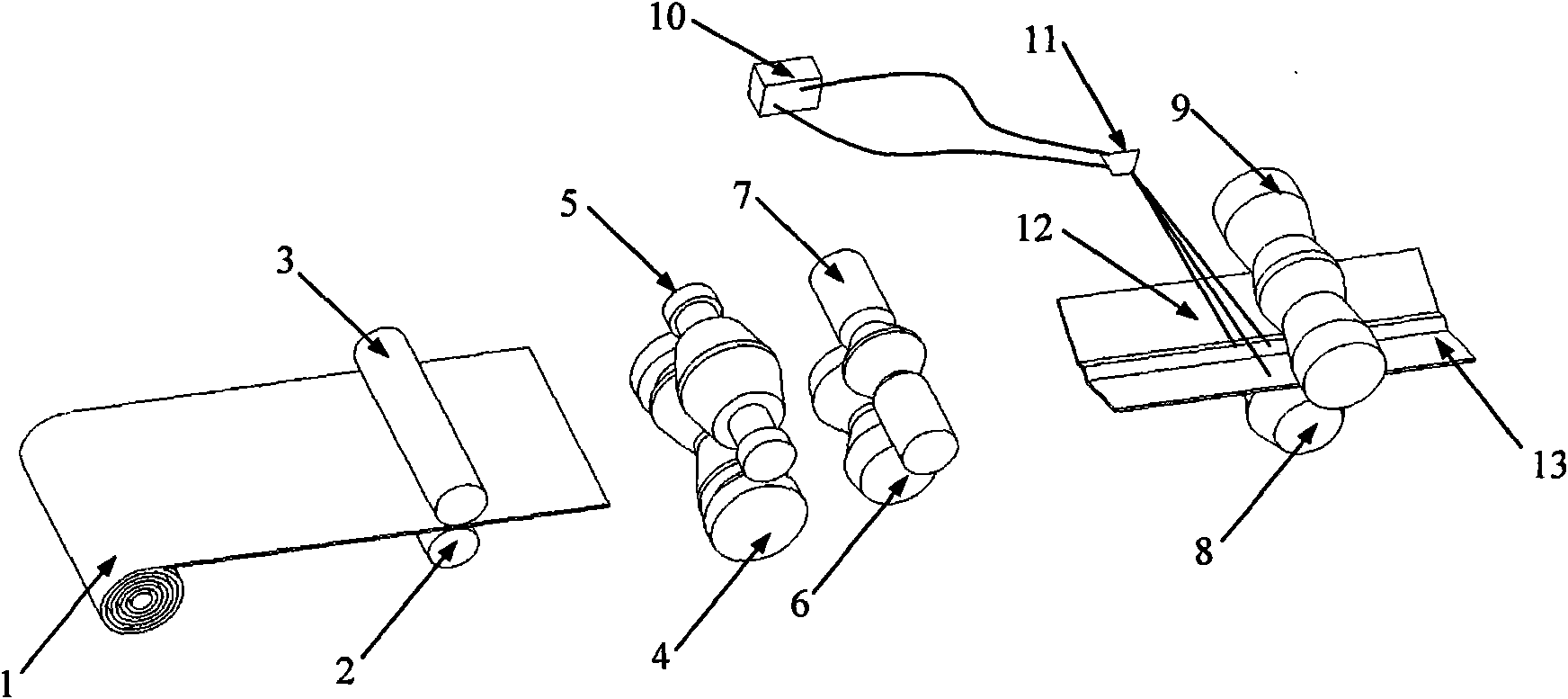

Method used

Image

Examples

Embodiment 1

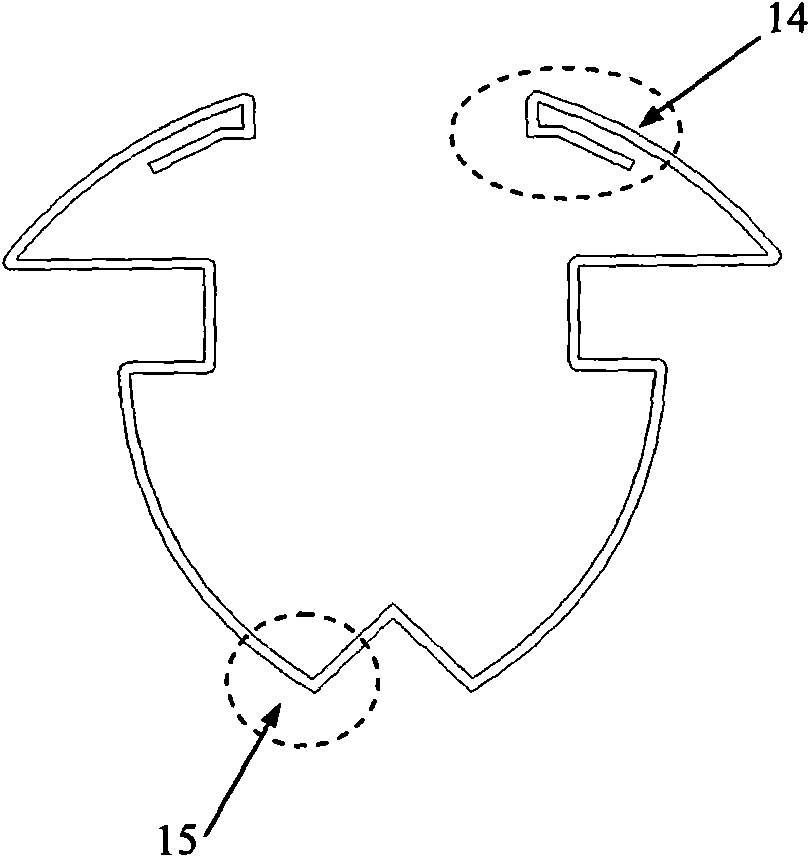

[0032] Using carbon dioxide laser, the forming section is as Figure 2A shown. At room temperature, a DP800 high-strength steel plate with a thickness of 1.5mm and a width of 72.32mm is formed, the forming speed is 80mm / s, the laser power is set to 300W, and the scanning speed is 6.5mm / s. The surface of the steel plate rises to 700°C in a short time, increasing The forming limit is increased, and after roll forming, such as Figure 2B Shown is a roll-formed section with a complex pointed shape.

Embodiment 2

[0034] Using a helium-neon laser, the forming section is as Figure 3A shown. Forming a Q235 plain carbon steel plate with a thickness of 1mm and a width of 140mm at room temperature, the forming speed is 100mm / s, the laser power is 1000W, the scanning speed is 6.5mm / s, and the spot diameter is 3mm. Figure 3C Shown is a roll-bent section with a ribbed structure.

Embodiment 3

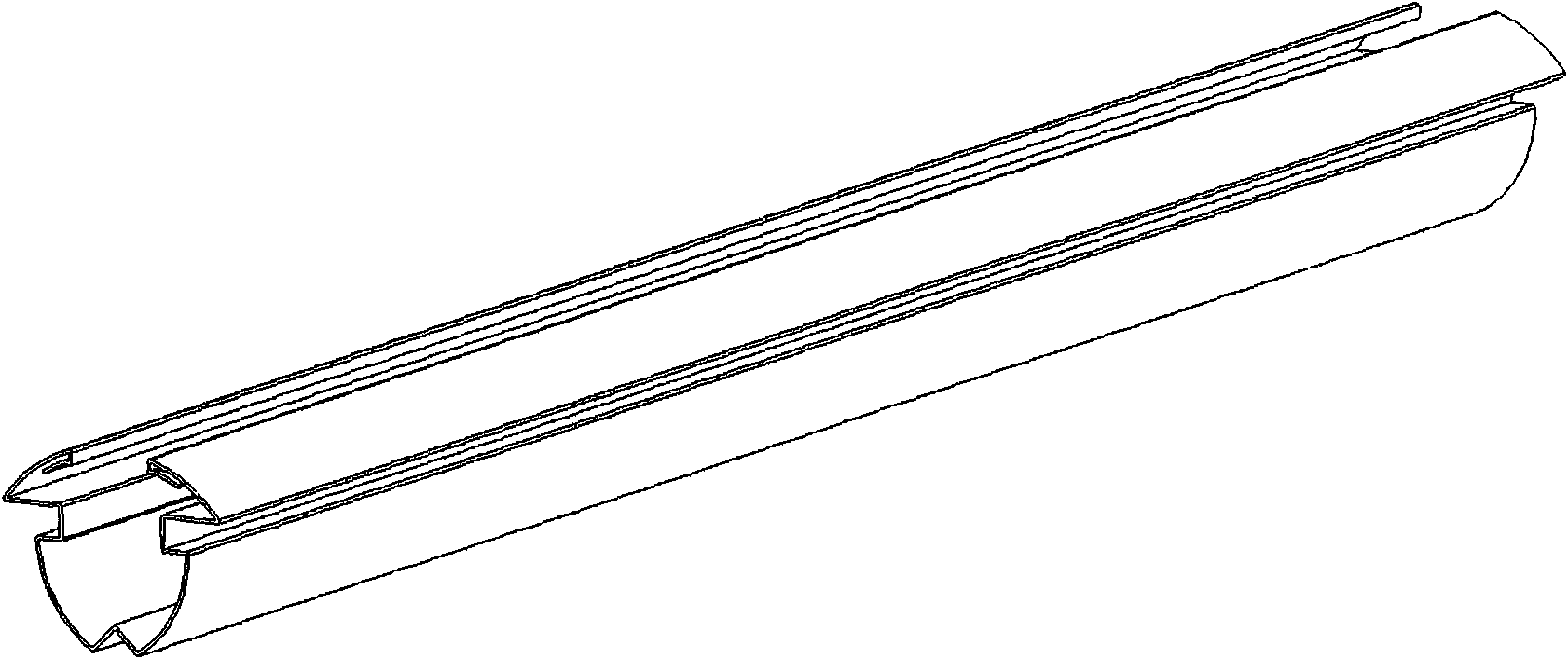

[0036] Using carbon dioxide laser, the forming section is as Figure 4A shown. Forming a SUS304 stainless steel plate with a thickness of 1.2mm and a width of 140mm at room temperature, the forming speed is 60mm / s, the laser power is 2000W, and the laser cutting speed is 3m / min. After roll forming, laser-assisted cutting is carried out. When the laser beam sweeps across the surface of the plate, the local temperature of the steel plate rises above 2000°C instantaneously. After sequential cutting, the following is obtained: Figure 4C U-shaped steel with six holes shown.

[0037] In summary, a laser-assisted roll forming device and method thereof according to the present invention applies laser-assisted heating to roll forming, which solves the problem of difficult forming due to work hardening in conventional roll forming, low cost. In addition, the present invention integrates roll forming, laser cutting and bending forming of plates, has good adjustability and flexibility...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com