Device and method for manufacturing vehicle longeron variable cross-section channel bar

An automobile longitudinal beam and variable-section technology, which is applied in the field of cold-formed production of automobile longitudinal beam variable-section channel steel, can solve the problems of low forming qualification rate, low production precision, low production efficiency, etc., and achieve good comprehensive mechanical properties. , The effect of good product surface quality and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

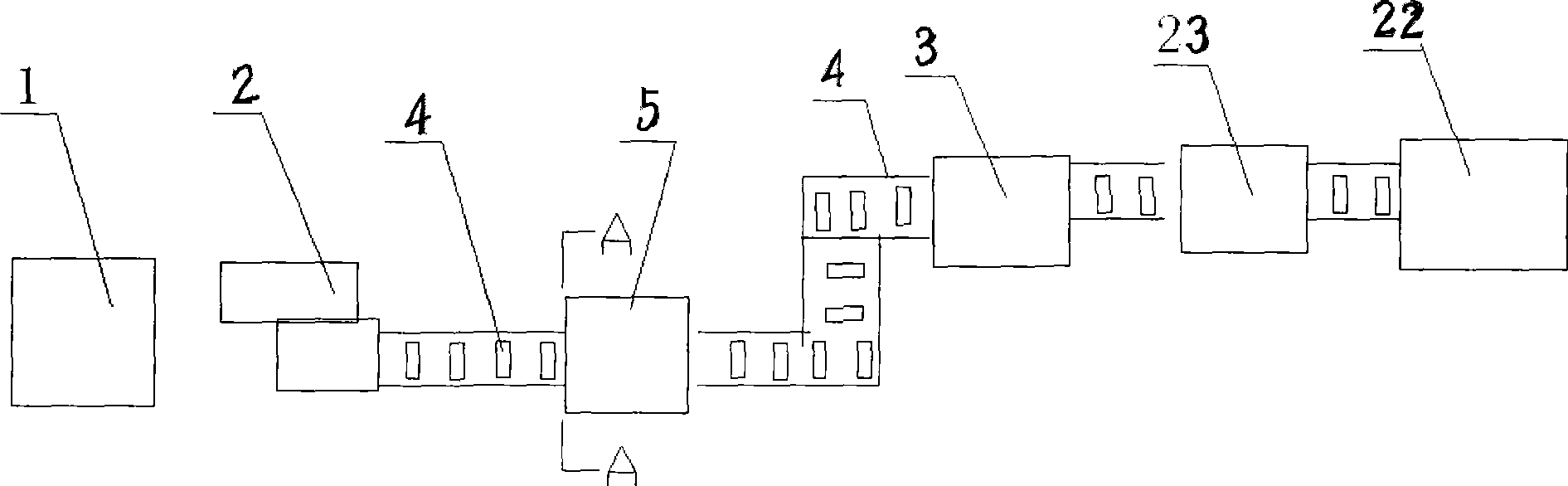

[0026] A device for producing variable-section channel steel for longitudinal beams of automobiles, mainly composed of a cold bending unit 1, a numerical control cutting machine or a flame cutting machine 2, an automatic welding machine 3, and a conveying roller table 4. It can be installed independently between the cutting machine 2 and the welding machine 3 and can also be connected to the extrusion device 5 with the conveying roller table 4. The welding machine 3 can also be assembled with the extrusion device 5, but the welding machine 3 must be connected to the extrusion device 5. After that, the work order cannot be reversed.

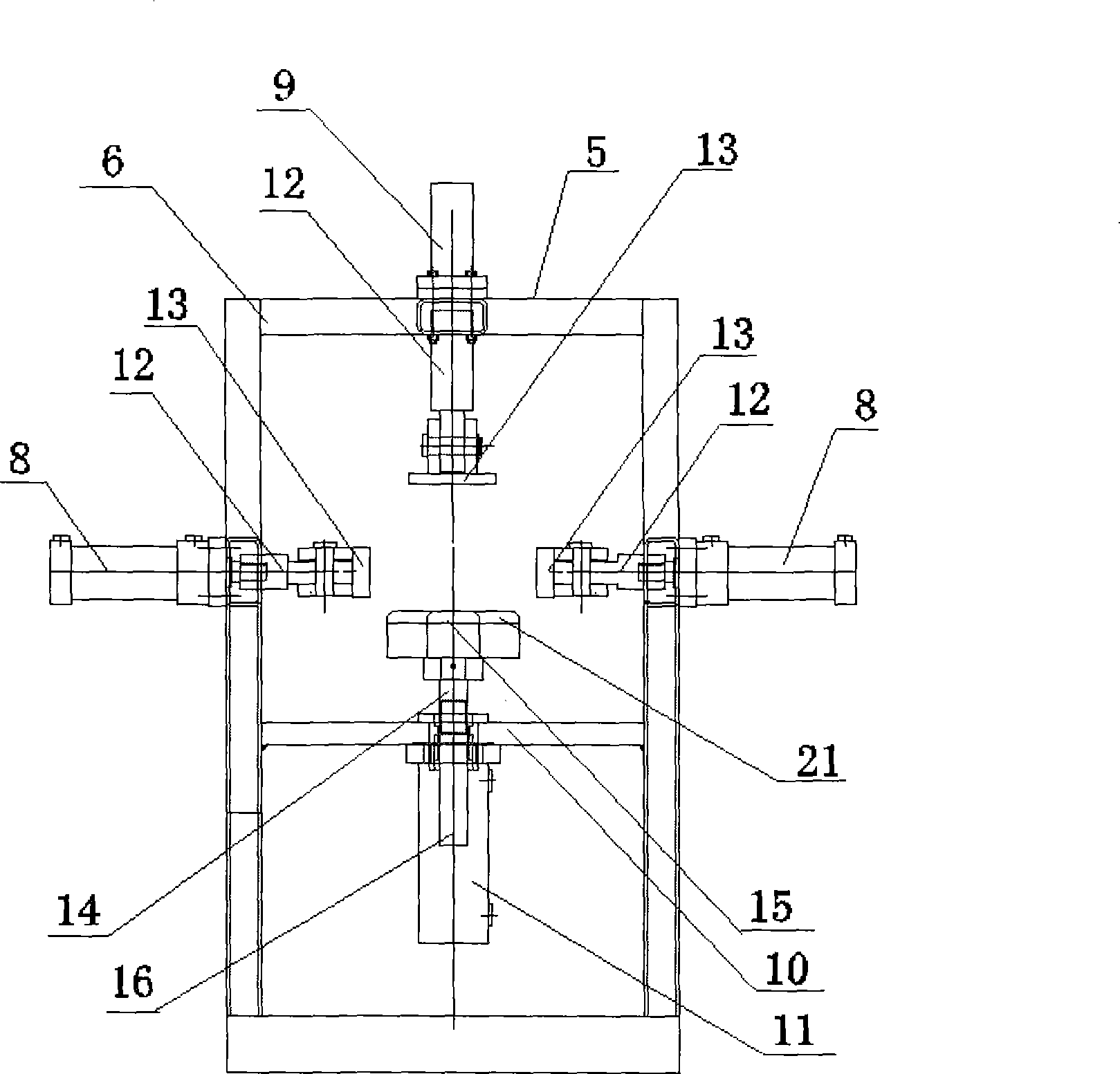

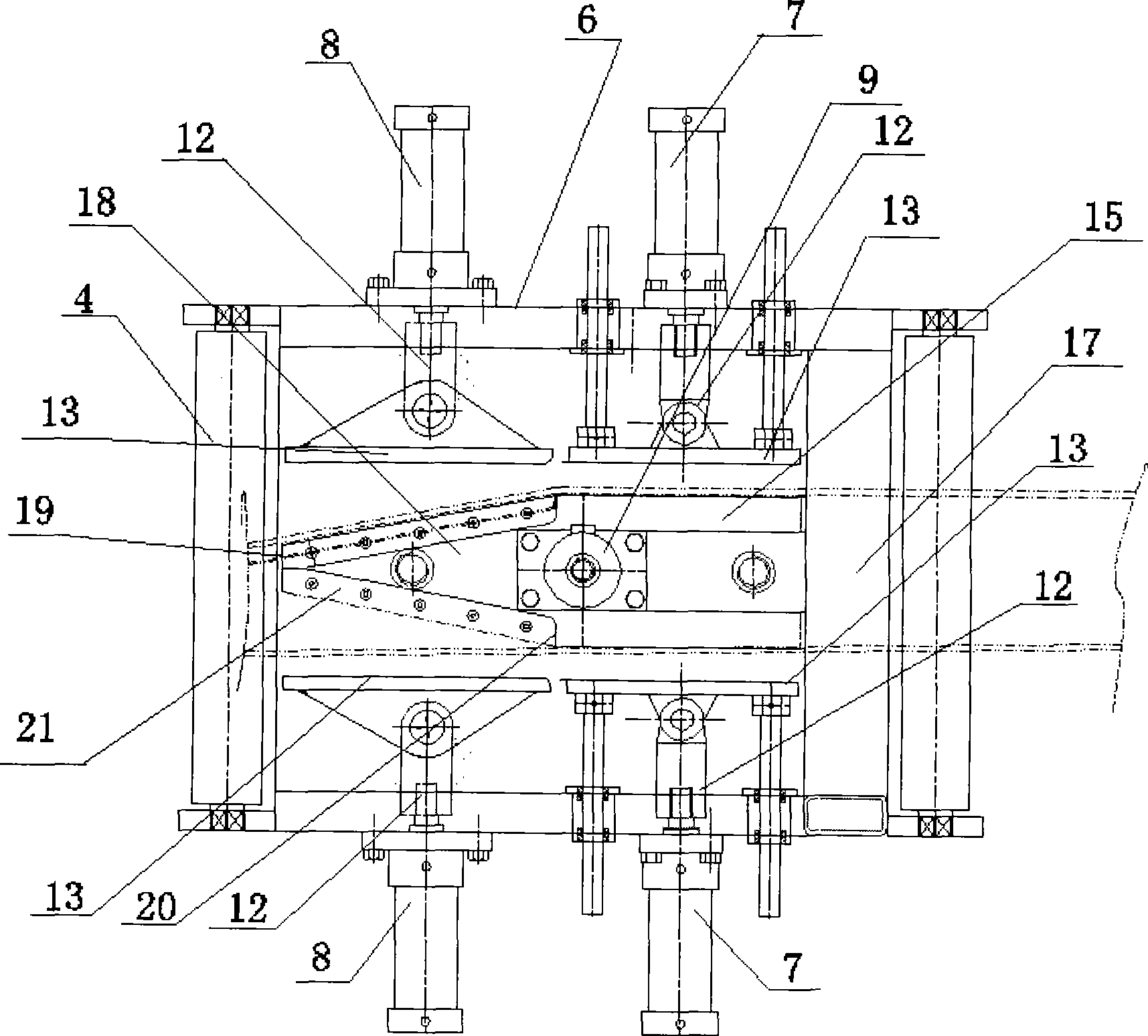

[0027] The composition of the extrusion device 5: the frame 6 is a frame type; the side positioning oil cylinder 7 is conventionally installed symmetrically on both sides of the frame 6, and the push rod 12 connected to the side positioning oil cylinder 7 is connected with the pressure plate 13 by bolts or welding; 6 The deformed cylinder 8 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com