Preparation method of esterified vegetable sponge and application thereof in organic matter absorption

A technology of esterifying silk and loofah, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve the problems of high regeneration cost of activated carbon, large loss of matrix, exhaustion of activated carbon, etc., and achieve good physical Chemical stability and thermal performance, excellent performance, and improved effect of esterification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

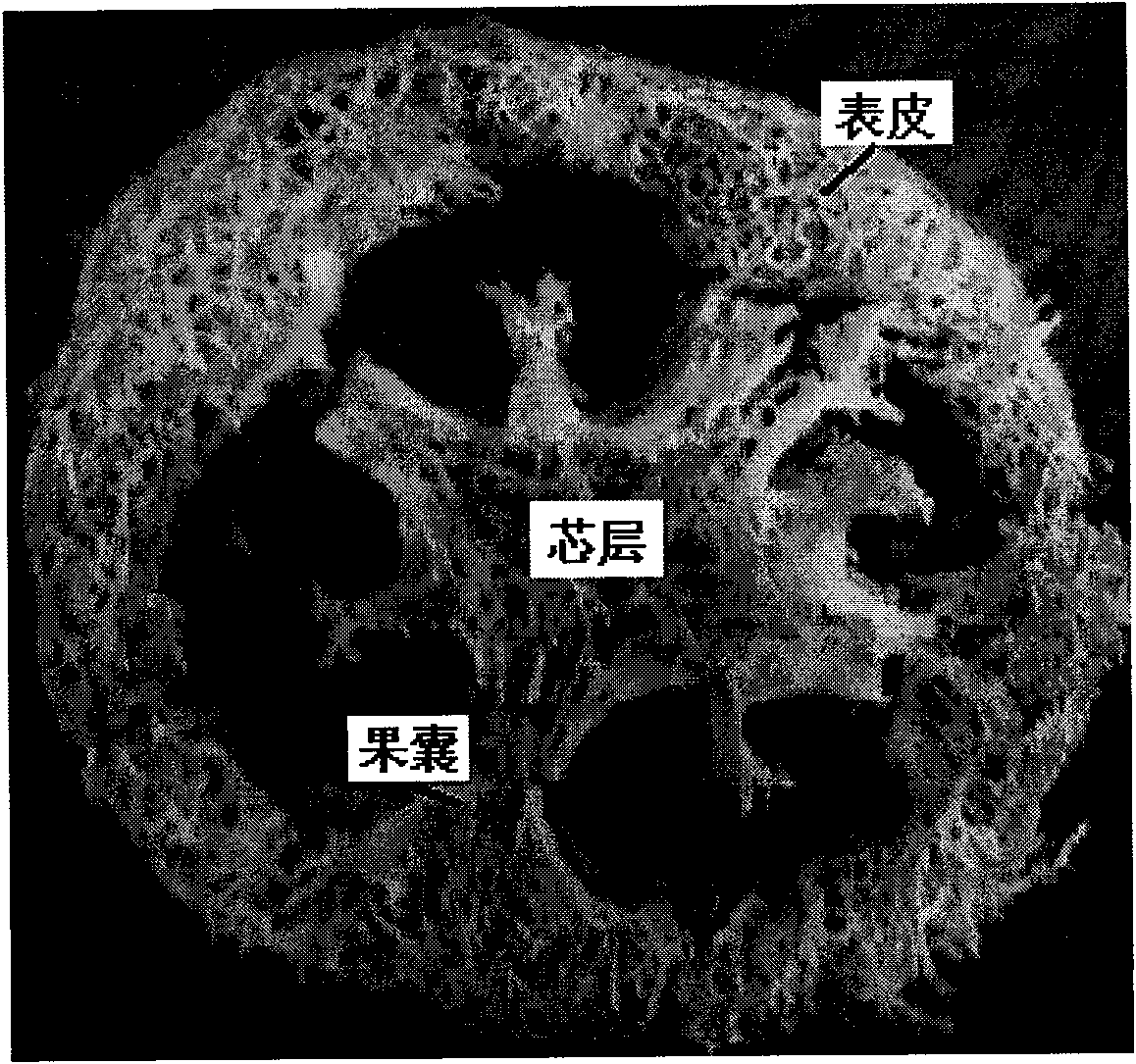

[0043] Alkali pretreatment: crush the natural loofah with a pulverizer and sieve, mix 30-80 mesh loofah with an appropriate amount of NaOH ethanol solution with a concentration of 30% by weight, alkalinize at room temperature for 24 hours, and then microwave intermittently at 700W Irradiate for 15 minutes; then transfer to a three-necked flask, reflux in a 70°C constant temperature water bath for 3h, wash with deionized water until neutral, and dry at 70°C;

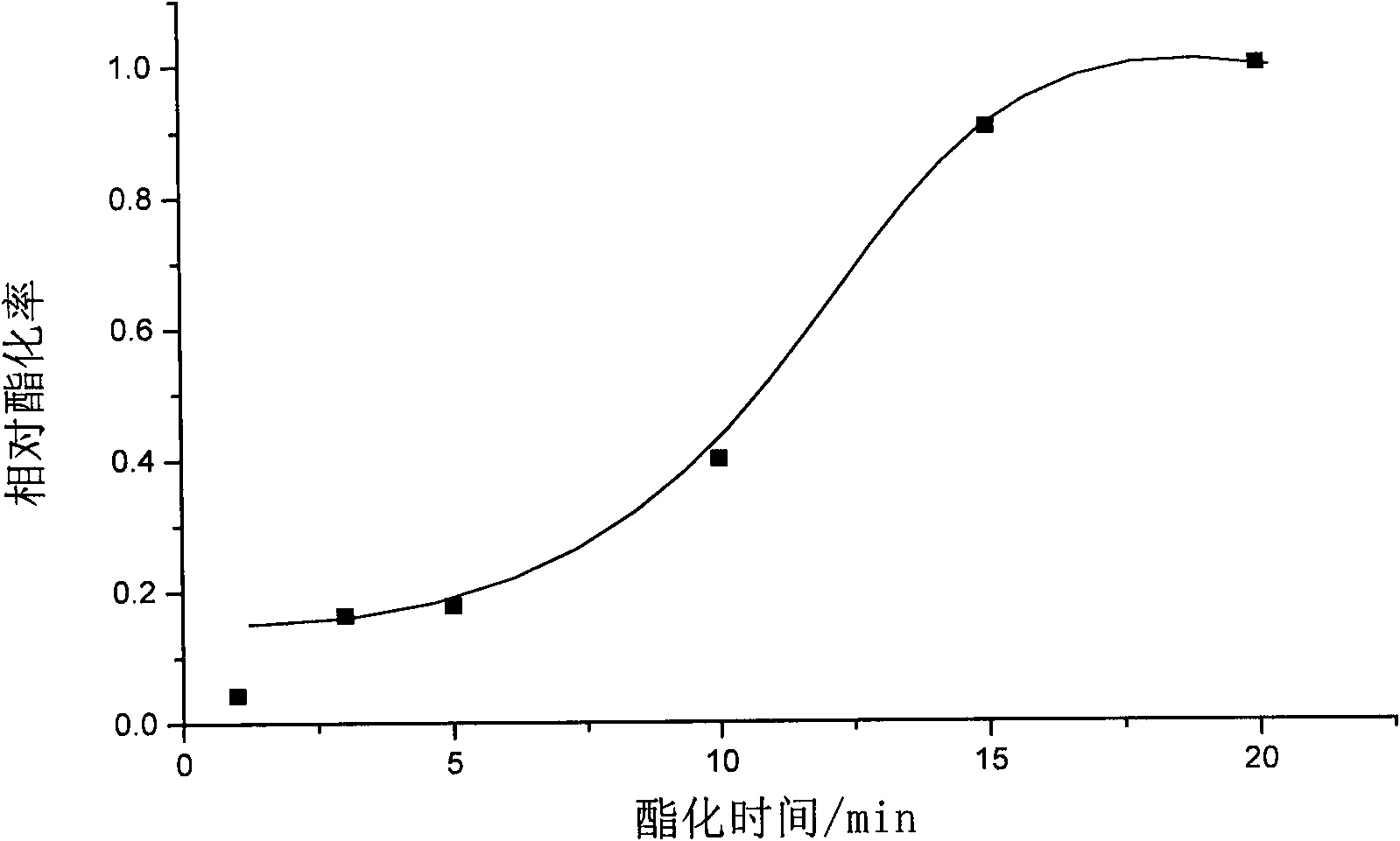

[0044] Preparation of esterified loofah: immerse the loofah after alkali pretreatment in acetic anhydride for 24 hours, then irradiate intermittently under 700W microwave conditions for 1min, 3min, 5min, 10min, 15min and 20min, and wash with deionized water until neutral Finally, dry at 70°C to obtain loofah powders with different esterification rates. The relationship between esterification rate and microwave radiation time is shown in the appendix figure 2 .

Embodiment 2

[0046] Alkali pretreatment: crush the natural loofah with a pulverizer and sieve, mix 30-80 mesh loofah with an appropriate amount of 30% NaOH / ethanol solution, soak for 24 hours, then take out the loofah, Spread it on a surface dish, irradiate intermittently under 700W microwave conditions for 1min, then extract it to neutral with deionized water, and dry it at 70°C to obtain alkali-treated loofah;

[0047] Preparation of esterified loofah: immerse the alkali-pretreated loofah in acetic anhydride for 24 hours, then take out the loofah, spread it on a watch glass, irradiate intermittently under 700W microwave conditions for 1min, and then extract it to medium with deionized water. After drying, dry at 70°C to obtain esterified loofah.

Embodiment 3

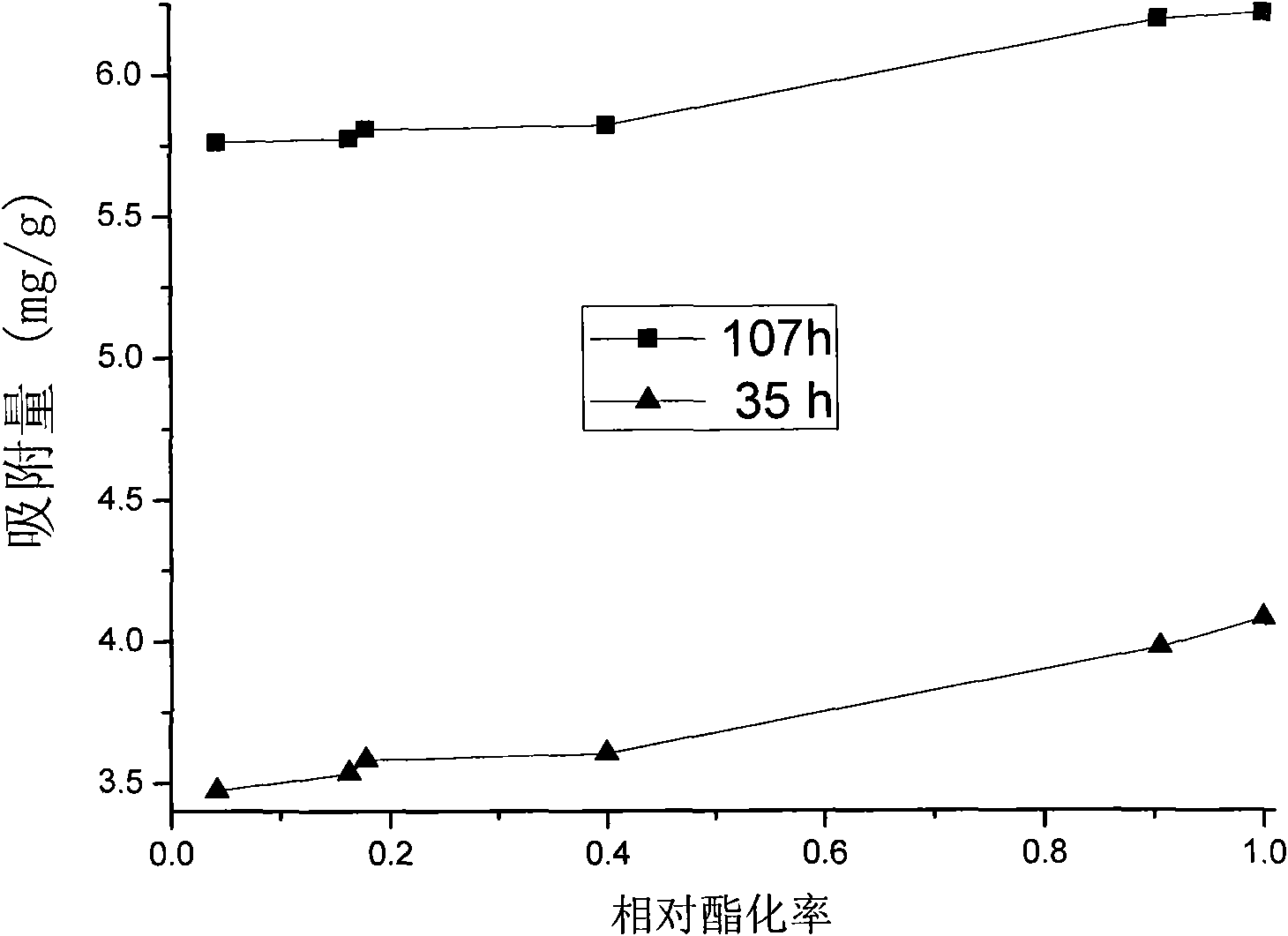

[0049] UV-Vis spectrophotometer was used to determine the adsorption capacity of esterified loofah on nitrobenzene.

[0050] (1) First measure the absorbance-concentration standard working curve of the nitrobenzene aqueous solution with an ultraviolet-visible spectrophotometer, and fit the equation to obtain the relationship between the absorbance and the concentration;

[0051] (2) Get 8 20mL test tubes, add 0.016g of different esterified loofahs respectively, then add 15mL of known nitrobenzene aqueous solution in each test tube, track the absorbance with the change of adsorption time with a UV-Vis spectrophotometer, And calculate the unit adsorption capacity Q of loofah at a certain moment according to the standard working curve equation A :

[0052] Q A = ρ A V A ( A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com