Heat-radiating substrate for alternating current LED light source

A technology of LED light source and heat dissipation substrate, which is applied in the field of heat dissipation substrate structure for AC LED light source, can solve the problems of performance and structure that cannot meet the requirements, decline in heat conduction and heat dissipation performance, and increased LED light attenuation, so as to improve electronic compatibility and expansion Small variation and excellent heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

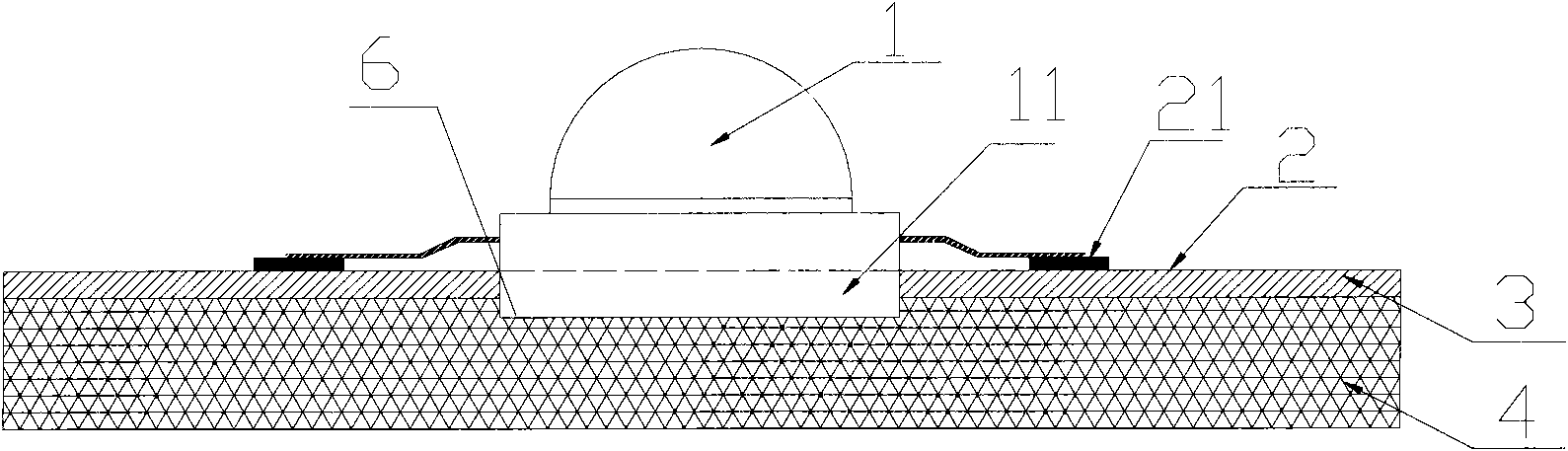

[0024] Such as figure 1 It can be seen from the structural schematic diagram of the heat dissipation substrate for LED light source of the present invention that the present invention designs and provides a heat dissipation substrate for AC LED light source with graphite as the heat dissipation seat layer. The basic structure of the heat dissipation substrate is divided into three layers, such as figure 1 As shown, it includes an LED light source 1 , a conductive layer 2 , an insulating layer 3 and a bottom layer 4 . Wherein conductive lines and power electrode pads 21 are distributed on the conductive layer 2 . The insulating medium of the intermediate insulating layer 3 generally adopts a high thermal conductivity epoxy glass fiber cloth bonding sheet or a special high thermal conductivity epoxy resin polymer; the thermal resistance is small, the bonding performance is excellent, it has the ability to resist thermal aging, and can withstand mechanical and thermal stress. ...

Embodiment 2

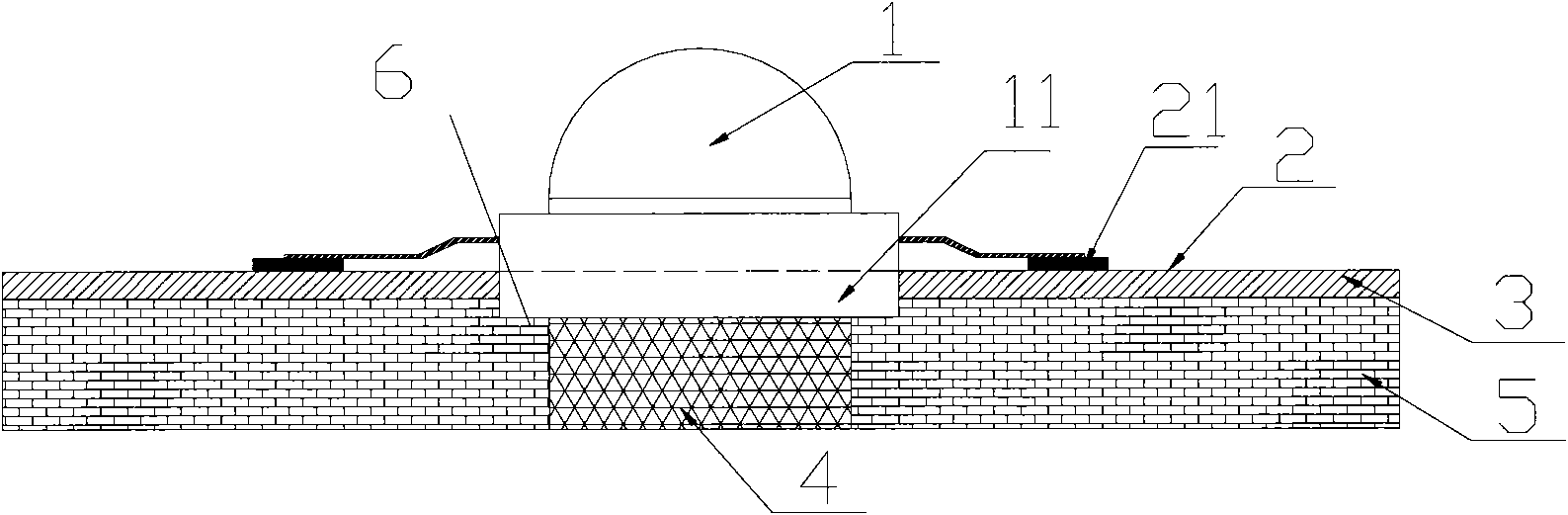

[0030] Such as figure 2 Shown is another structural combination of the heat dissipation substrate structure for the above-mentioned AC LED light source. This substrate structure can use graphite as a heat-conducting material and be embedded in other metal-based or non-metal-based heat-conducting substrates 5 to form a hybrid heat-conducting structure. The seat layer, the graphite layer is located directly below the heat sink of the LED light source 1, and the graphite wall is fully in contact with the through hole wall of other metal-based or non-metal-based heat-conducting substrate 5, and the heat is evenly transmitted along the two side walls. Two-dimensional plane to achieve the purpose of heat dissipation.

Embodiment 3

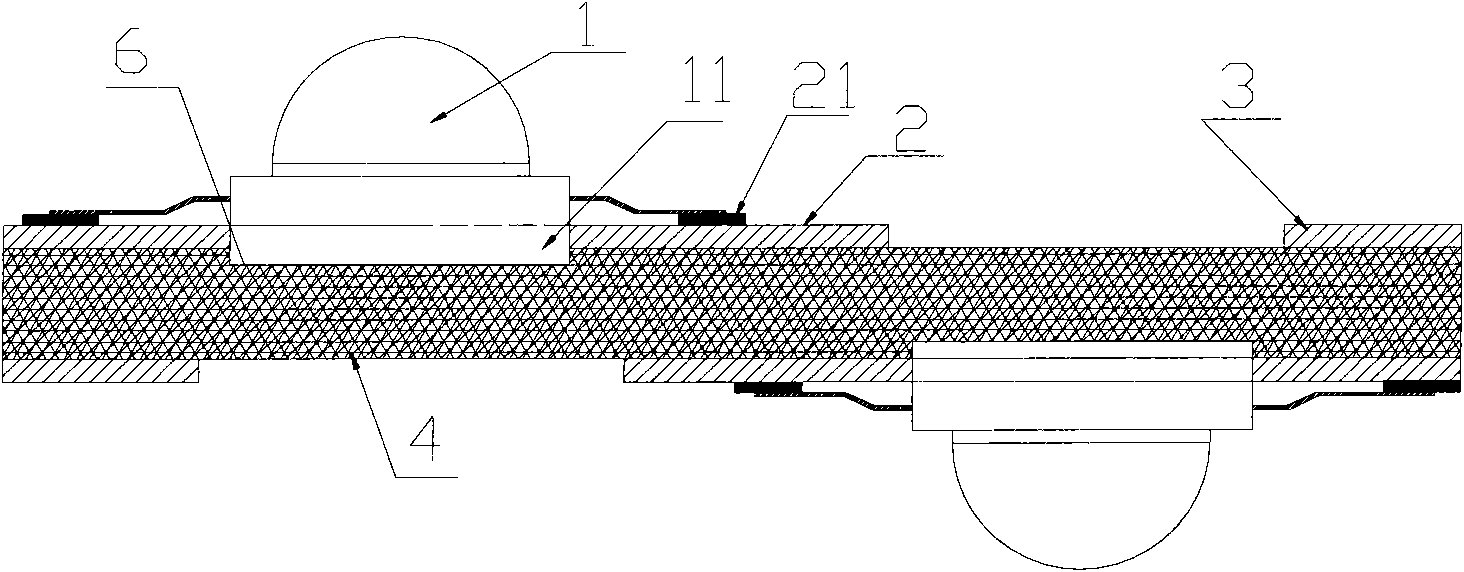

[0032] In addition to the above substrate structure with a single conductive layer, the structure of the heat dissipation substrate for an AC LED light source of the present invention can also be double-sided, and a conductive layer and an LED light source can also be provided under the bottom layer.

[0033] Such as image 3 What is shown is another structural combination of the heat dissipation substrate structure for the above-mentioned AC LED light source. The substrate structure is similar to the first embodiment, and both use graphite layer 4 as the seat layer of the heat dissipation substrate. The difference is that the fixing groove 6 , insulating layer 3 , conductive layer 2 and LED light source are arranged on the other side of the graphite layer in dislocation relative to the LED light source on the upper layer. The dislocation formed makes the graphite layer on the other side of the heat dissipation substrate corresponding to each LED light source exposed, so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com