Conveying pipe, concrete conveying machine and method for manufacturing conveying pipe

A conveying pipe and concrete technology, applied in the field of conveying pipes, can solve the problems such as the inability to realize the life design of the inner pipe of the conveying pipe, the high power consumption of the concrete conveying machinery, the inability to realize the life design of the conveying pipe, etc., and achieves light weight and small friction coefficient. , the effect of enhancing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

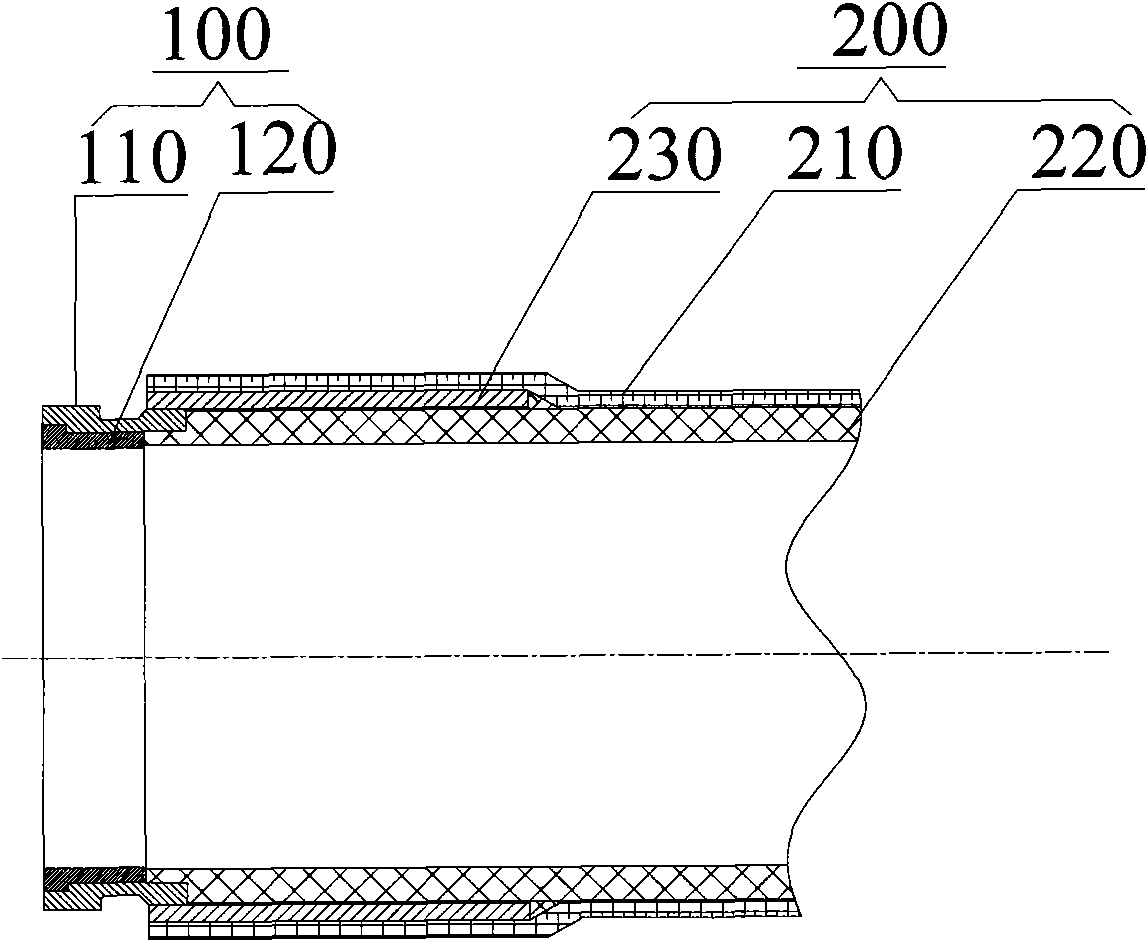

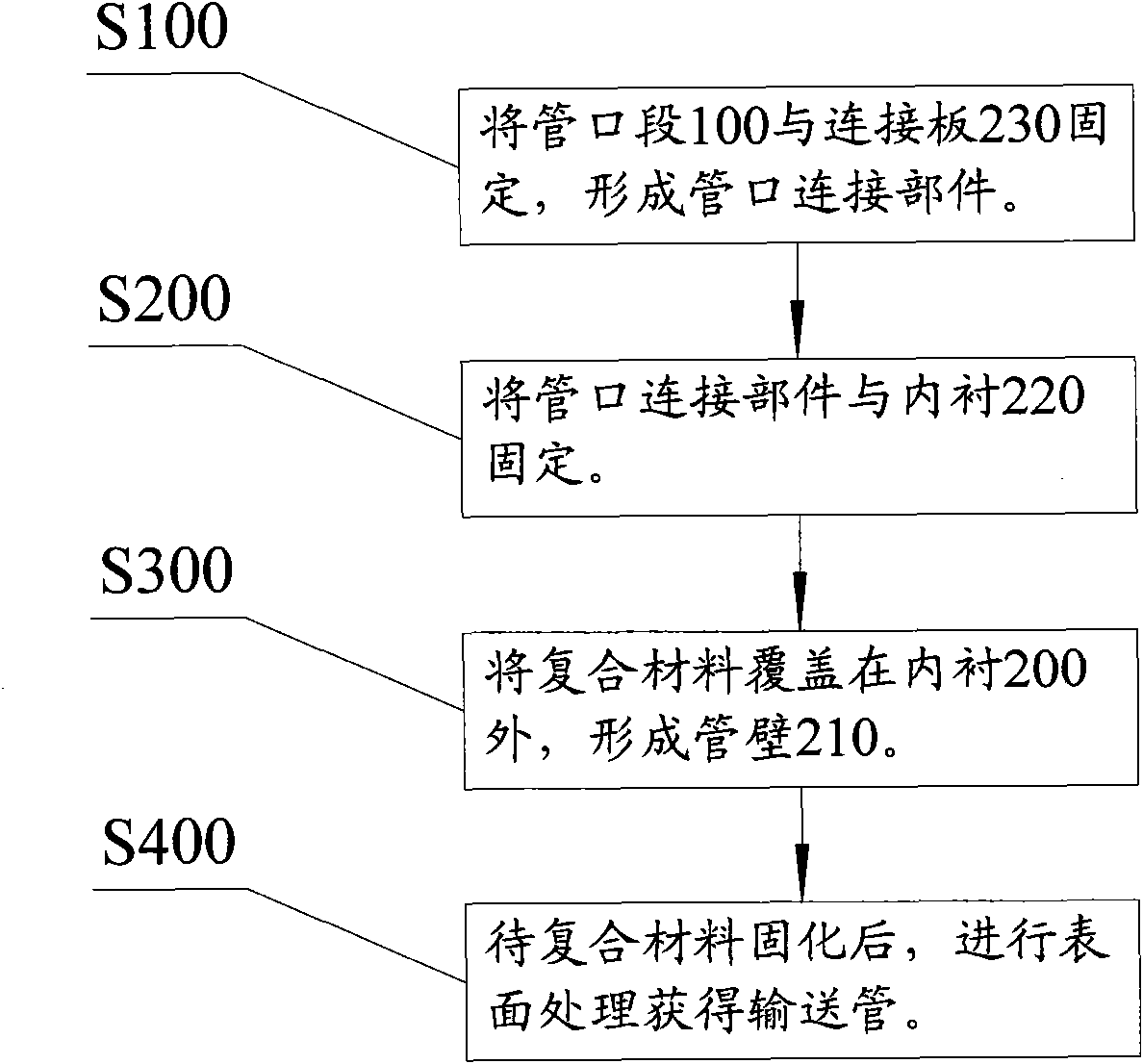

[0042] The delivery pipe provided in Embodiment 1 includes a nozzle section 100 and a pipe body 200; a flange structure can be provided on the nozzle section 100 to realize a reliable connection between the delivery pipes; the inner end of the nozzle section 100 and the pipe body 200 The ends are fixed. The pipe body 200 includes a pipe wall 210 and an inner lining 220 located in the pipe wall 210; the pipe wall 210 is made of a composite material, and the composite material is composed of resin and fiber. Of course, it can also be made in a composite material according to actual needs Add other materials to make the composite material have predetermined characteristics to meet actual needs. Liner 220 is made of ultra high molecular weight polyethylene.

[0043] like figure 1 As shown, in order to ensure the reliability of fixing the nozzle section 100 and the pipe body 200 , and further ensure the reliability of the conveying pipe to transport concrete, in this example, the...

Embodiment 2

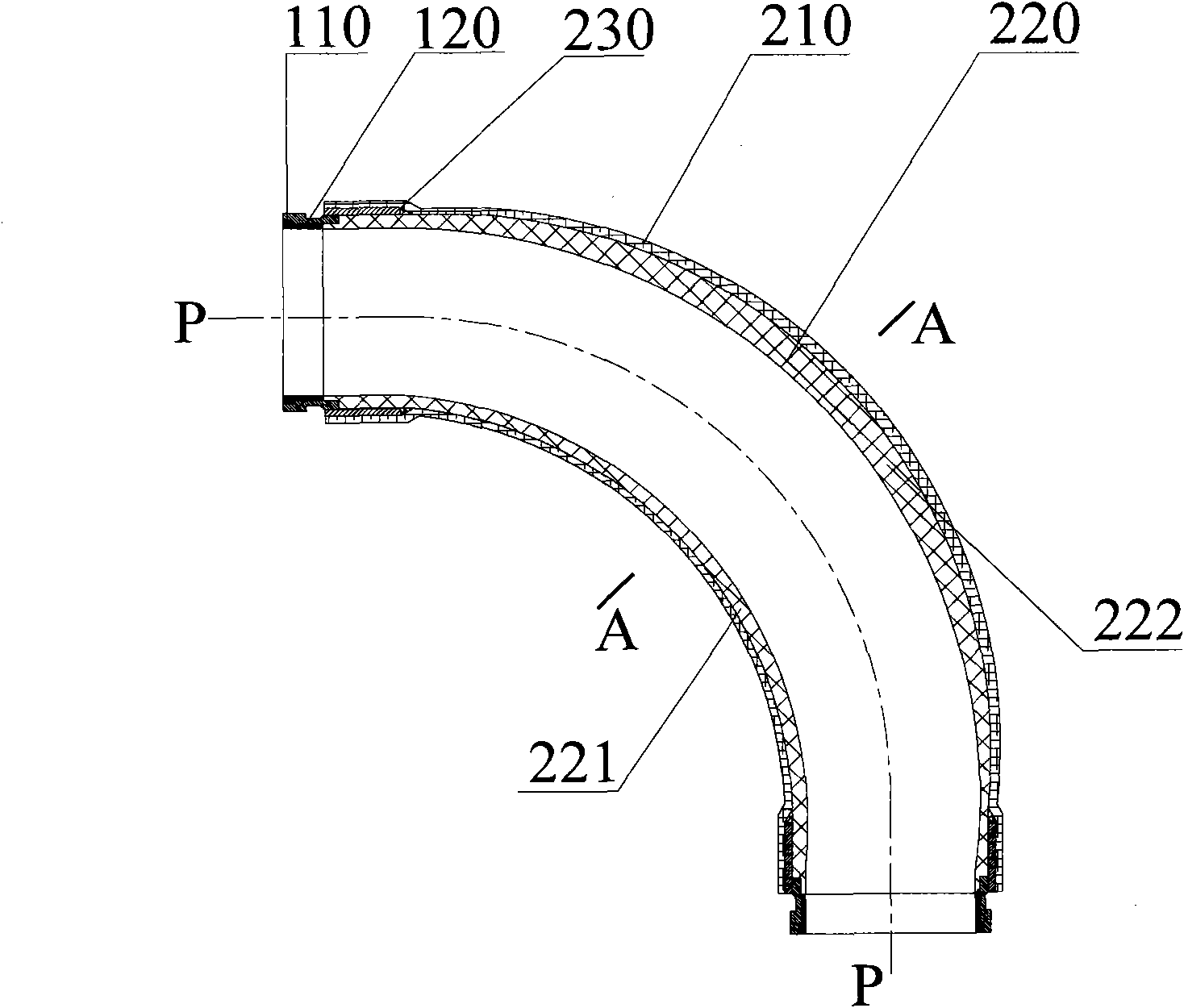

[0060] The basic structure of a delivery elbow provided by Embodiment 2 is the same as that of Embodiment 1, including a nozzle section 100 , a pipe body 200 , and the pipe body includes a pipe wall 210 , a lining 220 and a connecting plate 230 .

[0061] As shown, in this example, the thickness of the various parts of the liner 220 is not the same. In the transverse section, the thickness of the inner arc portion 221 of the lining 220 is smaller than the thickness of the outer arc portion 222 thereof. In this way, under the same condition of the inner liner 220 wear and wear resistance, the wear rate of the outer arc portion 222 is greater than the wear rate of the inner arc portion 221, because the thickness of the outer arc portion 222 is greater than the thickness of the inner arc portion 221, so it can be reduced. The gap between the service life of the small inner arc part 221 and the outer arc part 222; as image 3 As shown, the preferred technical solution is that, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com