Cation-anion co-doping n-type zinc-oxide-base transparent conducting film and preparation method thereof

A transparent conductive film, anion and cation technology, applied in the direction of ion implantation plating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of performance degradation, poor stability, unsatisfactory application, etc., to promote crystallization , Reduce lattice defects, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

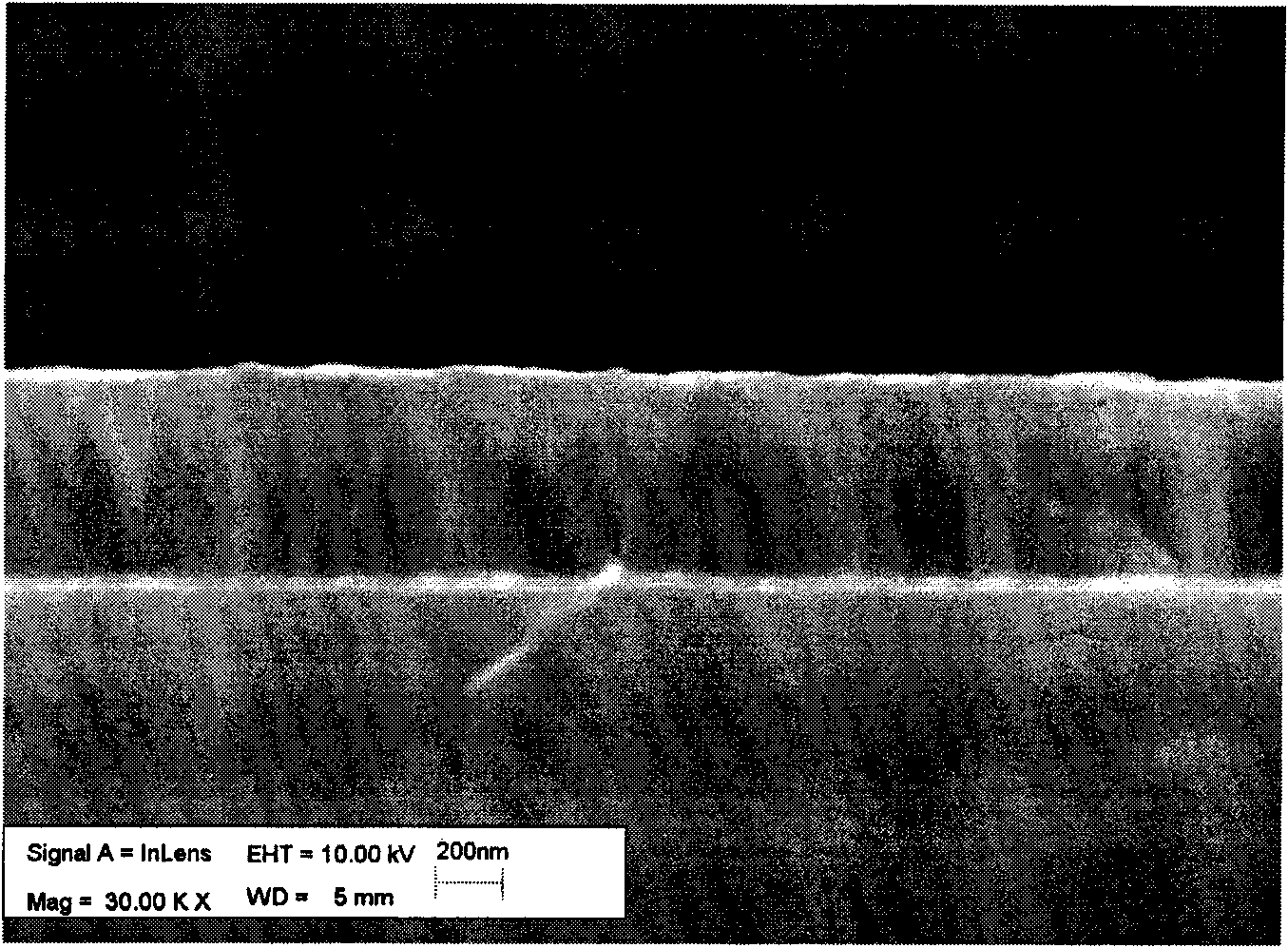

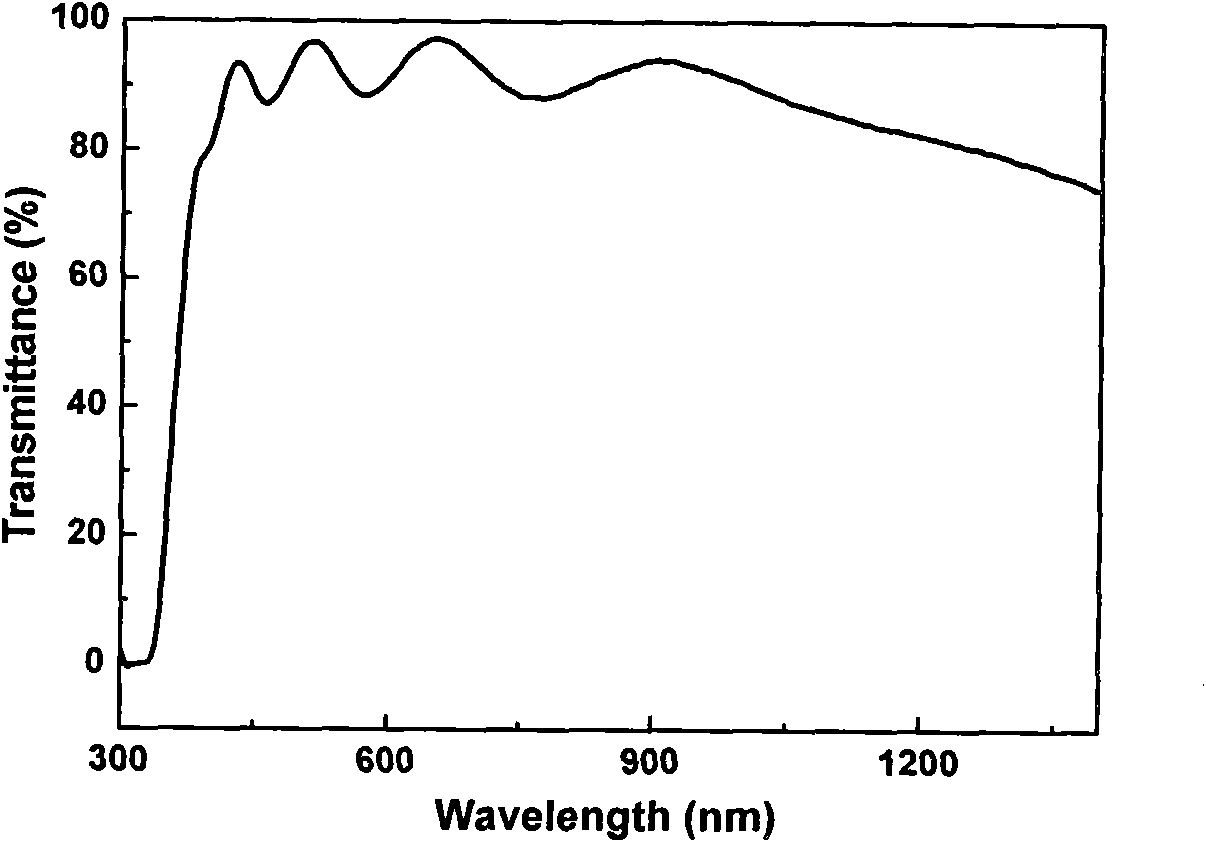

[0029] Using ZnO-based doping compound (ZnO:Al, F) as the target material, the doping ratios of Al and F are 2.0mol% and 1.0mol%, respectively, and ordinary glass is used as the substrate, and the background vacuum is pumped to 2.0×10 -4 Pa, with high-purity argon as the working gas, the working pressure was maintained at 1.0Pa, the substrate temperature was 150°C, the distance between the target and the substrate was set at 7.5cm, DC magnetron sputtering was used, and the sputtering power was 80W. The time is 40 minutes. The visible light transmittance of the film is above 90%, and the resistivity is 3.2×10 -4 Ω·cm, the retention rate of electrical conductivity and light transmittance is above 98% after accelerated aging for 50 hours in an environment with a temperature of 60 degrees Celsius and a relative humidity of 70%. The XRD pattern, SEM pattern, and transmission spectrum of the ZnO-based doped film are shown in Figure 1 to Figure 4, it was found that the obtained fi...

Embodiment 2

[0031] Using ZnO-based doping compound (ZnO:Al, F) as the target material, the doping ratios of Al and F are 5.0mol% and 2.0mol%, respectively, and ordinary glass is used as the substrate, and the background vacuum is pumped to 2.0×10 -4 Pa, using high-purity argon as the working gas, the working pressure is maintained at 1.0Pa, the substrate temperature is 150°C, the distance between the target and the substrate is set at 6.5cm, DC magnetron sputtering is used, and the sputtering power is 80W. The time is 40 minutes. The visible light transmittance of the film is above 86%, and the resistivity is 7.2×10 -4 Ω·cm, the retention rate of electrical conductivity and light transmittance is above 99% after accelerated aging for 50 hours in an environment with a temperature of 60 degrees Celsius and a relative humidity of 70%.

Embodiment 3

[0033] Using ZnO-based doping compound (ZnO:Al, F) as the target material, the doping ratio of Al and F is 0.25mol% and 5mol%, and using ordinary glass as the substrate, the background vacuum is pumped to 2.0×10 -4 Pa, with high-purity argon as the working gas, the working pressure is maintained at 1.2Pa, the substrate temperature is 150°C, the distance between the target and the substrate is set at 7cm, DC magnetron sputtering is used, the sputtering power is 120W, the deposition time After 40 min, the crystal grains grew obviously, and the crystalline quality of the film was significantly improved. The thickness of the film is about 1500nm, the transmittance of visible light is above 85%, and the resistivity is 9.2×10 -4 Ω·cm, the retention rate of electrical conductivity and light transmittance is above 90% after accelerated aging for 50 hours in an environment with a temperature of 60 degrees Celsius and a relative humidity of 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com