Method for producing high-purity manganese monoxide

A manganese monoxide, high-purity technology, applied in manganese oxide/manganese hydroxide and other directions, can solve the problem of impurity content that is difficult to meet the high impurity content of high-purity manganese monoxide and manganese trioxide, and cannot meet customer requirements, etc. Implementation, low impurity content, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

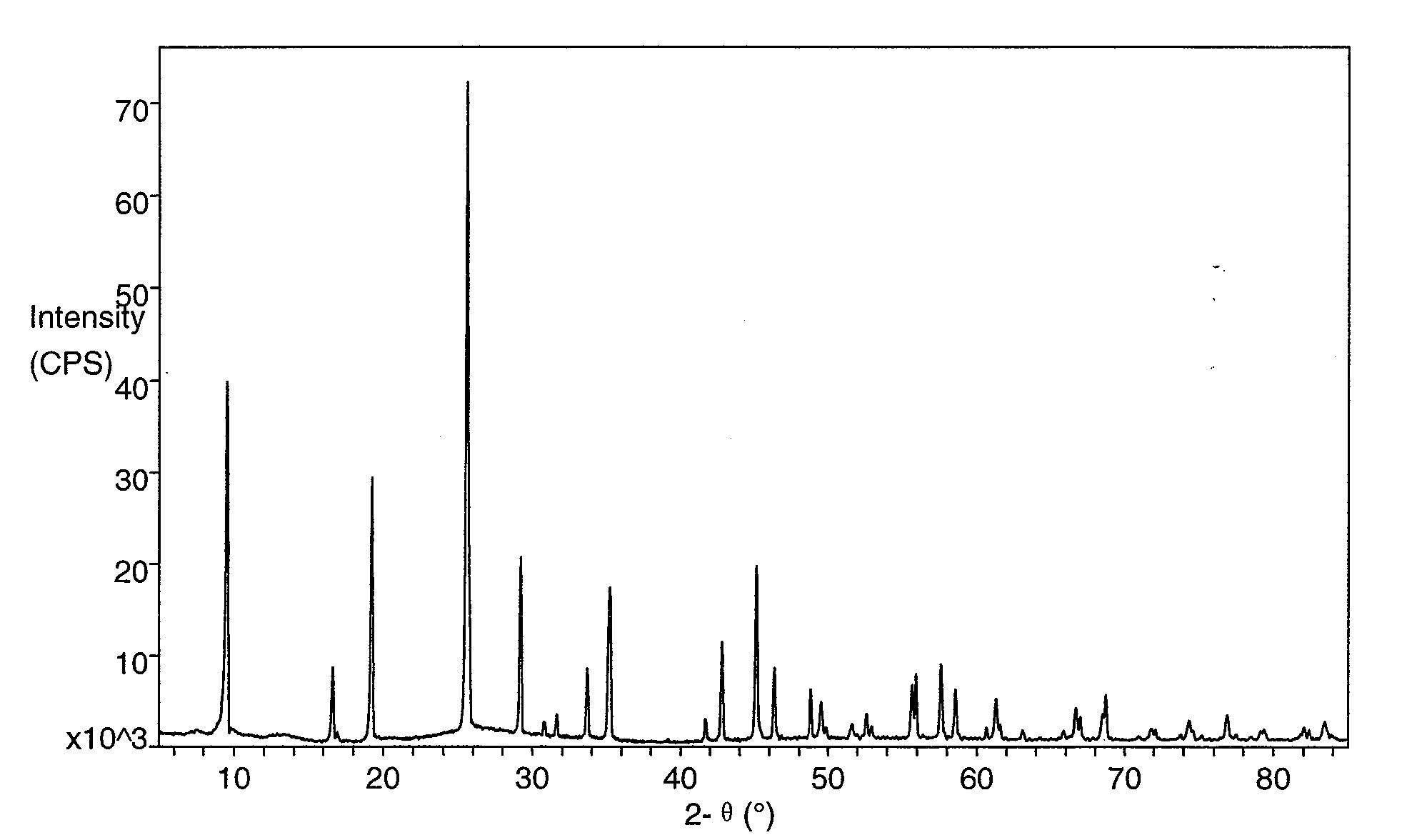

Embodiment 1

[0016] Example 1, take 100 grams of electrolytic manganese metal flakes, grind them to 100 mesh, place them in an atmosphere furnace, heat them to 400°C, feed water vapor at 2 liters per minute for 8 hours, and then add 1 liter per minute to Feed nitrogen in 1 minute, stop heating, be cooled to room temperature, obtain 158 grams of high-purity manganese monoxide with a purity of 99.9%.

Embodiment 2

[0017] Example 2, take 200 grams of electrolytic manganese metal flakes, grind them to 500 mesh, put them in an atmosphere furnace, heat them to 1000°C, feed water vapor at 3 liters / minute for 2 hours, and then add 2 liters / minute Feed argon in 1 minute, stop heating, cool to room temperature, obtain 316.5 grams of high-purity manganese monoxide with a purity of 99.9%.

Embodiment 3

[0018] Example 3, take 100 grams of electrolytic manganese metal sheet, grind it to 800 mesh, put it in an atmosphere furnace, heat it to 750 ° C, feed water vapor at 1.5 liters / minute for 6 hours, and then add 2 liters / minute Feed carbon dioxide in 1 minute, stop heating, be cooled to room temperature, obtain 158.2 grams of high-purity manganese monoxide with a purity of 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com