Integrated artificial cornea and preparing method thereof

An artificial cornea, one-piece technology, applied in the direction of eye implants, etc., to achieve the effect of preventing separation, preventing leakage and infection, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

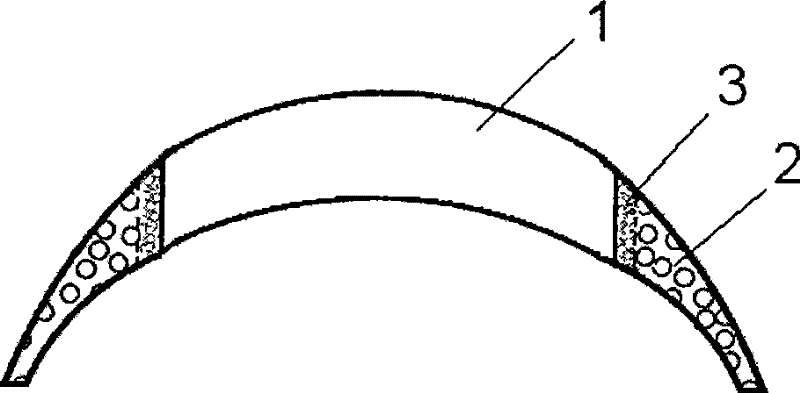

[0024]Dissolve 10g of polyvinyl alcohol in 80g of dimethyl sulfoxide (DMSO), add 10g of graphite powder (10-100μm in particle size) and mix well, then add 120g of sodium chloride particles (10-300μm in particle size) and mix well The obtained mixture is put into a special mold for artificial cornea and molded (as shown in the figure, the crescent shape is formed by curved edges with different curvatures), and then frozen together with the mold at -20°C to -40°C for 30 minutes, and then After thawing at room temperature for 30 minutes, take it out of the mold and soak in deionized water for 48-96 hours to completely dissolve and remove sodium chloride, fully dissolve the solvent DMSO and replace it with water to obtain porous polyvinyl alcohol with micropores distributed in the structure Hydrogel porous structure skirt scaffold blank.

[0025] According to the requirements of use, punch a hole with a diameter of 5-7 mm in the center of the above-mentioned skirt bracket blank, a...

Embodiment 2

[0028] Dissolve 10g of polyvinyl alcohol in 83g of dimethylsulfoxide (DMSO), add 7g of graphite powder (10-100μm in particle size) and mix well, then add 150g of sodium chloride particles (10-300μm in particle size) and mix well The obtained mixture is put into a special mold for artificial cornea, and then molded together with the mold at -20°C to -40°C for 30 minutes, then thawed at room temperature for 30 minutes, taken out of the mold and soaked in deionized water for 48 to 48 minutes. After 96 hours, the sodium chloride was completely dissolved and removed, and the solvent DMSO was fully dissolved and replaced by water to obtain a porous polyvinyl alcohol hydrogel porous structure skirt stent blank with micropores distributed in the structure.

[0029] According to the requirements of use, punch a hole with a diameter of 5-7mm in the center of the above-mentioned skirt stent blank, and add an appropriate amount of 20wt% polyvinyl alcohol solution (the solvent is water / DMSO...

Embodiment 3

[0032] Dissolve 10g of polyvinyl alcohol in a mixed solvent of 84g of dimethylsulfoxide and water (water / DMSO mixture containing 20wt% water), add 6g of graphite powder (10-100μm in particle size) and mix well, then add 100g of sodium chloride Particles (particle size range 10-300μm) and stirred evenly to obtain a mixture, take the mixture and put it in a special mold for artificial cornea and mold it, freeze it together with the mold at -20℃~-40℃ for 30min, and then thaw at room temperature for 30min , taken out from the mold and soaked in deionized water for 48 to 96 hours to completely dissolve and remove sodium chloride, fully dissolve the solvent DMSO and replace it with water to obtain a porous polyvinyl alcohol hydrogel porous structure with micropores distributed in the structure Skirt bracket blanks.

[0033] Punch a hole with a diameter of 5-7mm in the center of the above-mentioned skirt bracket blank, add an appropriate amount of 20wt% polyvinyl alcohol solution (th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com