Piezoelectric ceramic composition and piezoelectric device

A technology of piezoelectric ceramics and piezoelectric devices, applied in piezoelectric/electrostrictive/magnetostrictive devices, manufacturing/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, etc., capable of Solve problems such as complex production methods and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

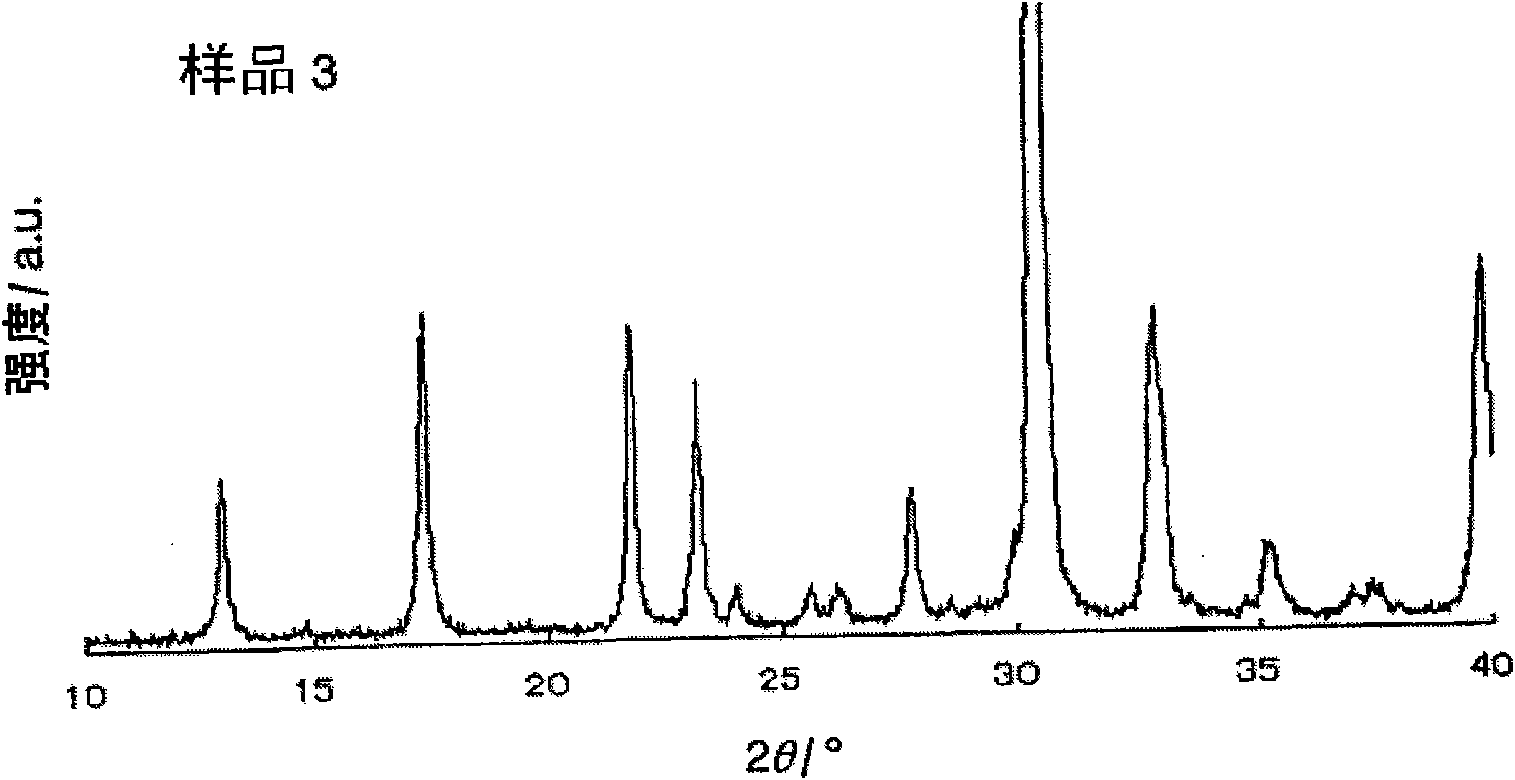

experiment example 1

[0039] Sodium carbonate (Na 2 CO 3 ), bismuth oxide (Bi 2 o 3 ), titanium oxide (TiO 2 ), cobalt oxide (CoO) and lanthanide oxides (lanthanum oxide (La 2 o 3 ), cerium oxide (Ce 2 o 3 ), praseodymium oxide (Pr 2 o 3 ), neodymium oxide (Nd 2 o 3 ), ytterbium oxide (Yb 2 o 3 )) raw material powders to prepare various raw material powder mixtures. In various examples, to form 0.967 (Bi 0.5 Na 0.48 Bi 4 Ti 4 o 15 )-0.033CoO (wherein 0<Ln / (Na+Bi+Ln)≤0.04) piezoelectric ceramic composition is weighed as the final product. In Comparative Examples, raw materials were weighed in such a way that the following four compositions were formed.

[0040] (1) Bi 0.5 Na 0.5 Bi 4 Ti 4 o 15

[0041] (2)0.967(Bi 0.5 Na 0.48 Bi 4 Ti 4 o 15 )-0.033CoO

[0042] (3) Bi 0.5 Na 0.48 Bi 4 Ti 4 o 15 , where La / (Na+Bi+La)=0.002

[0043] (4) Bi 0.5 Na 0.48 Bi 4 Ti 4 o 15 , where La / (Na+Bi+La)=0.04

[0044] Each raw powder mixture was blended with ethanol and subjec...

experiment example 2

[0063] The piezoelectric device (piezoelectric ceramic composition) of Sample 3 of Experimental Example 1 and the piezoelectric devices of Samples 15 and 16 corresponding to those in which Group 2 elements Ba and Sr were added to the composition of Sample 3 (piezoelectric ceramic composition) were tested. The Curie temperature (Tc) of the ceramic composition) and the degree of deterioration of the piezoelectric distortion constant under heat treatment at 600° C. for 1 hour.

[0064] More specifically, the raw material powders used for Sample 3 were the same as those of Experimental Example 1. In Samples 15 and 16, raw materials were weighed in such a manner that the following compositions were formed as final products.

[0065] (1)0.967(Bi 0.5 Na 0.48 ) Bi 4 Ti 4 o 15 -0.033CoO, where La / (Na+Bi+La)=0.01, and (Bi 0.5 Na 0.48 ) replaced by 25 mol% of Ba

[0066] (2)0.967(Bi 0.5 Na 0.48 ) Bi 4 Ti 4 o 15 -0.033CoO, where La / (Na+Bi+La)=0.01, and (Bi 0.5 Na 0.48 ) rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com