Method for selectively removing TaN metal gate electrode layer

A metal gate and electrode layer technology, applied in the field of selective removal of metal gate electrode layer, selective removal of TaN metal gate electrode layer, can solve the problems of low selection ratio, inapplicable selective removal of TaN metal gate electrode layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

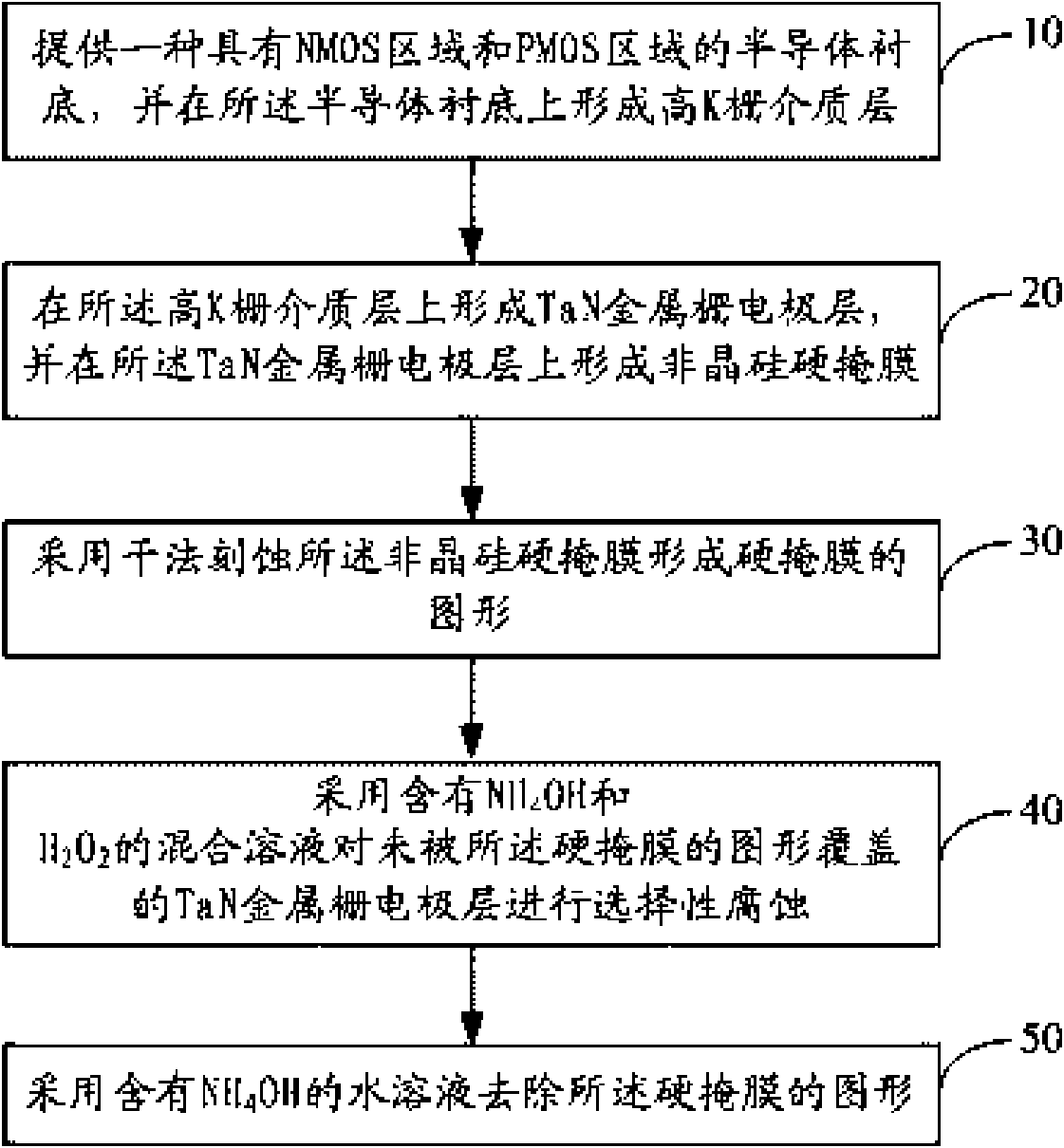

[0031] figure 1 It is a flowchart of a method for selectively removing a TaN metal gate electrode layer according to an embodiment of the present invention. Such as figure 1 As shown, the method includes the following steps:

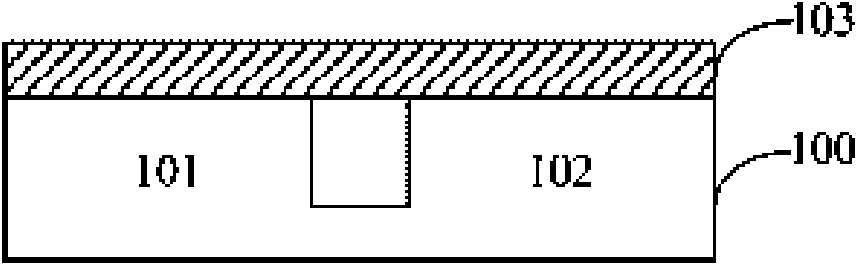

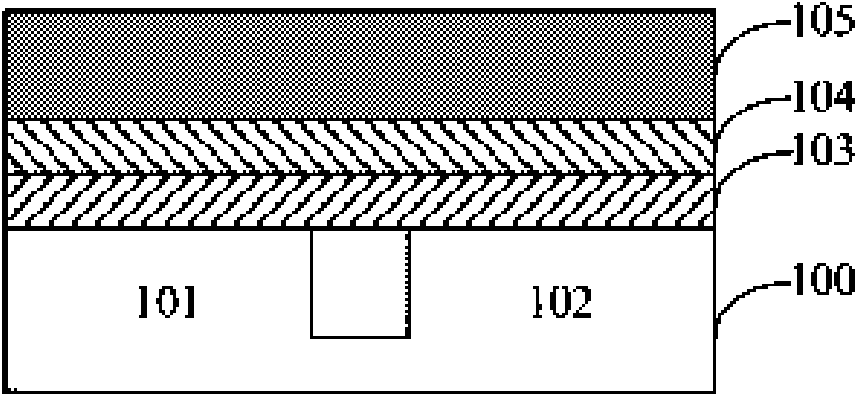

[0032] Step 10: providing a semiconductor substrate 100 having an NMOS region 101 and a PMOS region 102 , and forming a high-K gate dielectric layer 103 on the semiconductor substrate 100 .

[0033] The high-K gate dielectric layer 103 is made of HfO 2 , HfON, HfAlO, HfAlON, HfTaO, HfTaON, HfSiO, HfSiON, HfZrO, HfZrON, HfLaO or HfLaON, and its thickness is 2 nm to 4 nm. The high-K gate dielectric layer 103 can be formed by conventional deposition methods, such as physical vapor deposition,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com