Iodine-doped titanium-based film material and preparation method thereof

A thin-film material, iodine-doped technology, applied in photosensitive devices, semiconductor/solid-state device manufacturing, electrolytic capacitors, etc., can solve the problem of not being reasonably and effectively introduced into visible light responsive thin films, and achieve high photoelectric absorption efficiency and controllable The effect of strong reproducibility and repeatability, strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Iodine doped TiO 2 Preparation of nanocrystals: at a stirring speed of 500 rev / min, drop 4ml of acetic acid into 20ml of tetraisopropoxytitanium, keep stirring for 20 minutes, then add 100ml of iodic acid in water, and in the resulting mixed solution, iodine and titanium The molar ratio is 0.1:1, heated to 80°C in a water bath, and after stirring for 30 minutes, adjust the pH value to 3, and then heat in an oil bath at 200°C for 12 hours to obtain iodine-doped TiO 2 Nanocrystalline milky liquid, in which TiO 2 The solid content is 20%, and a 200W ultrasonic titanium probe is used to ultrasonically disperse at a frequency of 15 times / second.

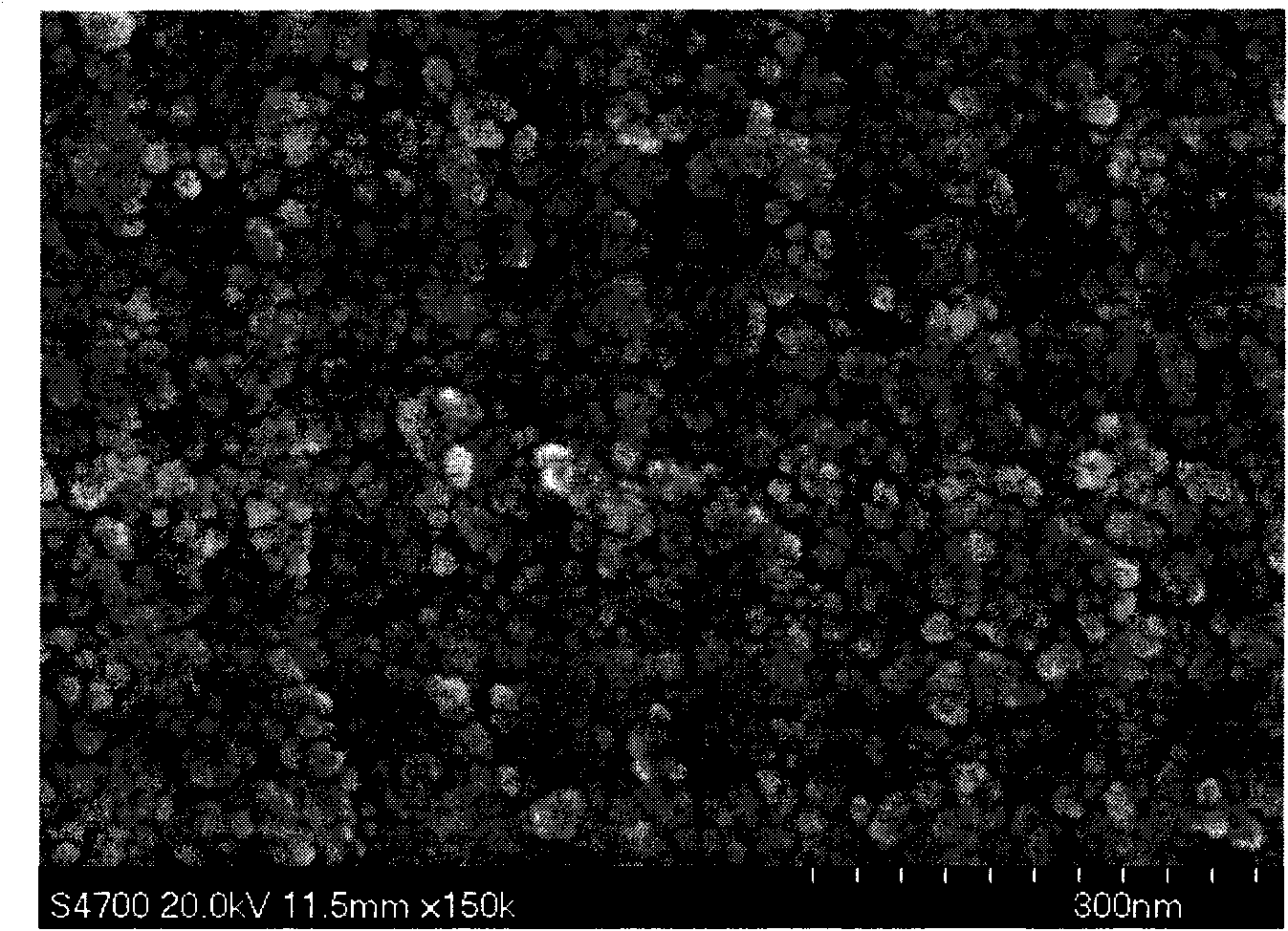

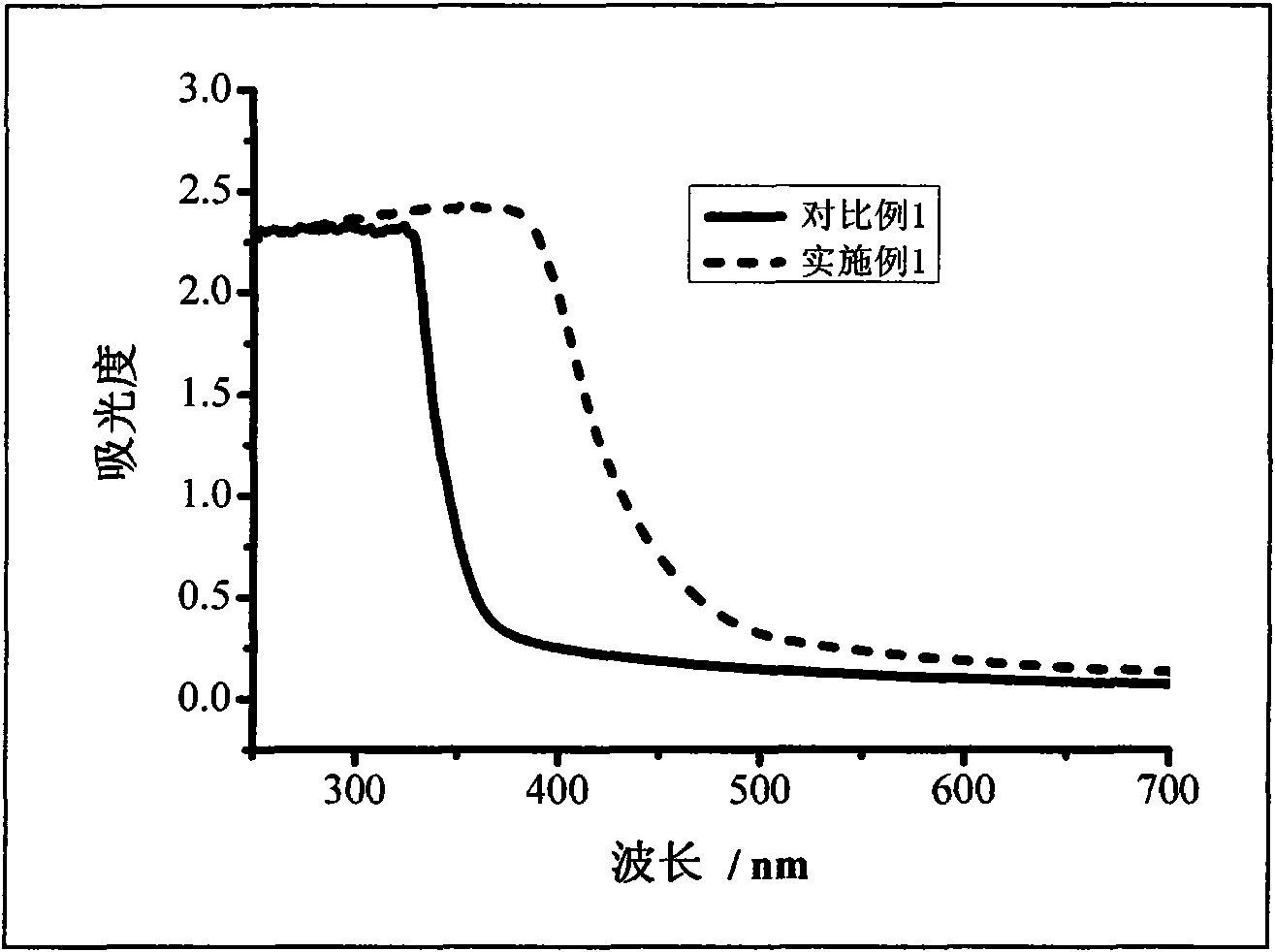

[0032] from figure 1 It can be seen that iodine doped TiO 2 The size of the nanocrystal is 10-20nm.

[0033] 2) Preparation of I-TNC film: add 0.005g polyethylene glycol 20000 (PEG20000) to 3ml iodine-doped TiO 2 In the milky liquid of nanocrystals, after fully grinding, add deionized water to adjust the concentration to ob...

Embodiment 2

[0035] 1) Iodine doped TiO 2 The preparation of nanocrystal: with embodiment 1 step 1);

[0036] 2) Sulfur-doped TiO 2 Preparation of large particles: At room temperature, the iodine element is ultrasonically dissolved in titanium tetraisopropoxide at a molar ratio of iodine to titanium of 0.1:1, stirred at a stirring rate of 500 rpm for 24 hours, and then placed in an oven at 100°C placed in the middle for 12 hours, and finally calcined at 500°C for 5 hours to obtain iodine-doped TiO 2 Large particles;

[0037] like figure 2 , it can be seen that the iodine-doped TiO prepared by this method 2 Large particles include irregular lumps and spheroids, and the diameter of spherical particles is 1-2 μm.

[0038] 3) Preparation of I-TBP film: 0.005g PEG20000 and 0.1g iodine doped TiO 2 Add 3ml iodine-doped TiO to large particles 2 After mixing and grinding in the milky liquid of nanocrystals and dispersing evenly, add deionized water to adjust the concentration to obtain TiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com