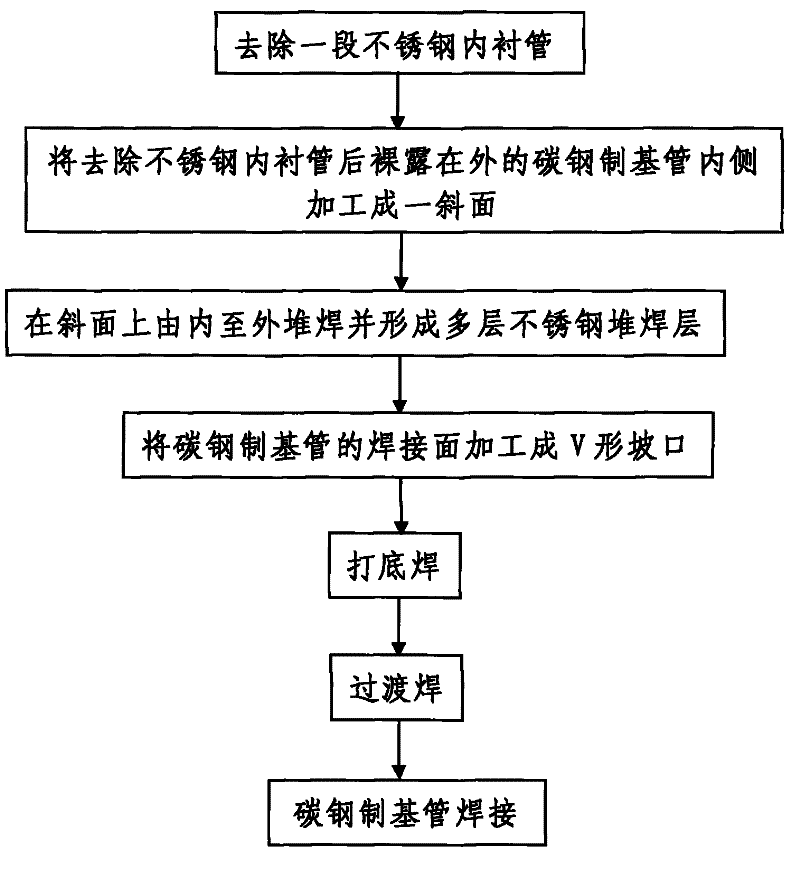

Method for welding composited tube at bonding interface of carbon steel/stainless steel machinery

A technology of interface compounding and welding method, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of increasing the welding difficulty of the composite pipe, difficult alignment of the base layer and the lining layer, low one-time pass rate of flaw detection, etc. Excellent mechanical properties and corrosion resistance, avoiding oxidation and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In this embodiment, the welded carbon steel / stainless steel mechanical bonding interface composite pipe 10 is a composite pipe composed of a stainless steel lining pipe 1 made of 316L stainless steel and a carbon steel base pipe 2 made of 20G carbon steel, and Its specification is Ф76×(7+2)mm.

[0062] Step one, welding groove treatment, the treatment process is as follows:

[0063] 101. Using conventional mechanical processing methods, at the end of the composite pipe 10 to be welded carbon steel / stainless steel mechanical bonding interface, a section of stainless steel lining pipe 1 with a length of 10 mm is removed from the outside to the inside.

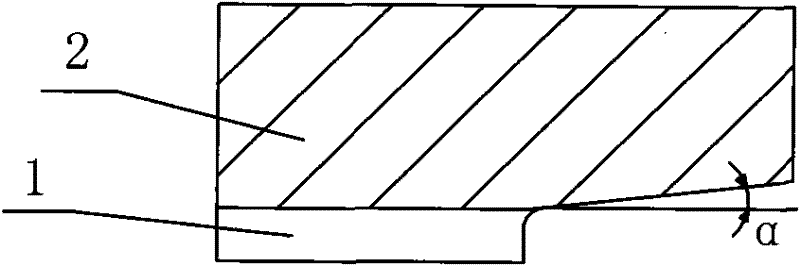

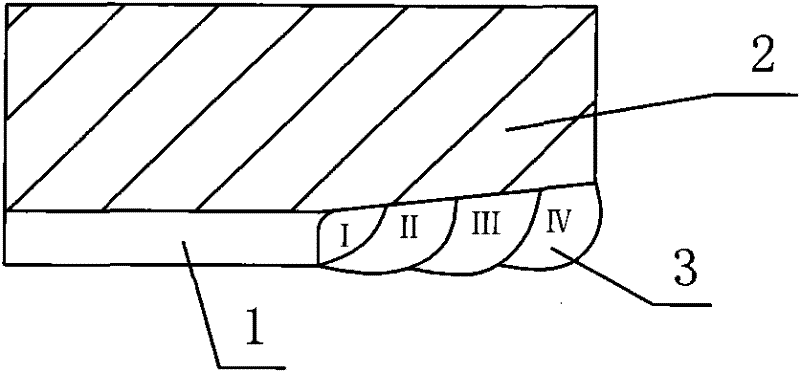

[0064] 102. The inner side of the carbon steel base tube 2 exposed outside after removing the stainless steel lining tube 1 is processed from the outside to the inside to form an inwardly inclined inclined plane and the inclined angle α of the inclined plane is 5°, see details figure 2 .

[0065] 103. Under argon protection, use ...

Embodiment 2

[0080] In this embodiment, the welded carbon steel / stainless steel mechanical bonding interface composite pipe 10 is a composite pipe composed of a stainless steel lining pipe 1 made of 316L stainless steel and a carbon steel base pipe 2 made of 20G carbon steel, and Its specification is Φ56×(5+1.5)mm. The difference from embodiment 1 is that: in step 101, a conventional machining method is used, at the end of the composite pipe 10 at the carbon steel / stainless steel mechanical bonding interface to be welded, a section of stainless steel lining pipe 1 with a length of 8 mm is removed from outside to inside; In 102, the inclination angle α of the inclined plane processed from the outside to the inside is 3°; the welding current during surfacing in step 103 is 90A, and the flow rate of the shielding gas used in the welding process is 13L / min. After the surfacing welding is completed, a total of three stainless steel surfacing layers 3 are formed from the inside to the outside on ...

Embodiment 3

[0086] In this embodiment, the welded carbon steel / stainless steel mechanical bonding interface composite pipe 10 is a composite pipe composed of a stainless steel lining pipe 1 made of 316L stainless steel and a carbon steel base pipe 2 made of 20G carbon steel, and Its specification is Φ96×(9+3)mm. The difference from embodiment 1 is: in step 101, a conventional machining method is used, at the end of the composite pipe 10 at the carbon steel / stainless steel mechanical bonding interface to be welded, a section of stainless steel lining pipe 1 with a length of 13 mm is removed from the outside to the inside; In 102, the inclination angle α of the inclined surface processed from the outside to the inside is 8°; the welding current during surfacing in step 103 is 90A, and the flow of shielding gas used in the welding process is 17L / min. After the surfacing is completed, a total of 5 layers of stainless steel surfacing 3 are formed from the inside to the outside on the inclined s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com