Detection method of inorganic membrane assembly

A detection method and membrane module technology, applied in the testing of machines/structural components, by detecting the appearance of fluid at the leak point, measuring devices, etc., can solve problems such as limiting large-scale application, affecting normal production, delaying time, etc. The effect of reducing labor costs, small workload, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

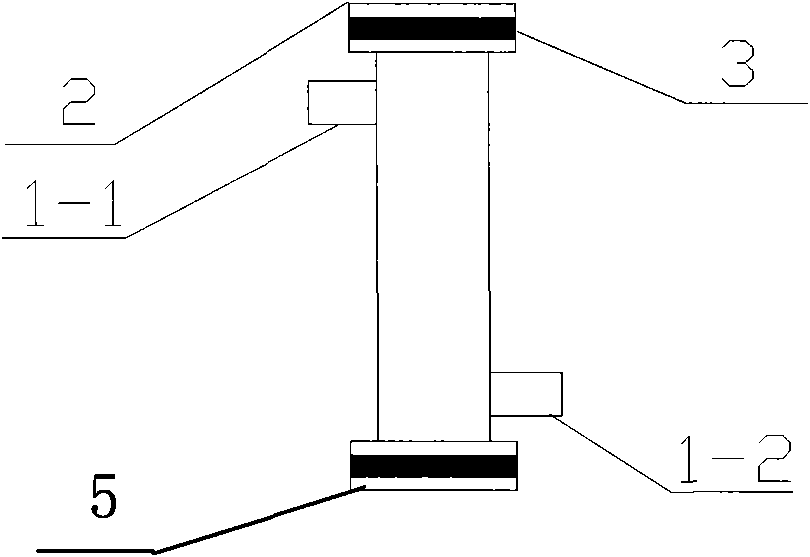

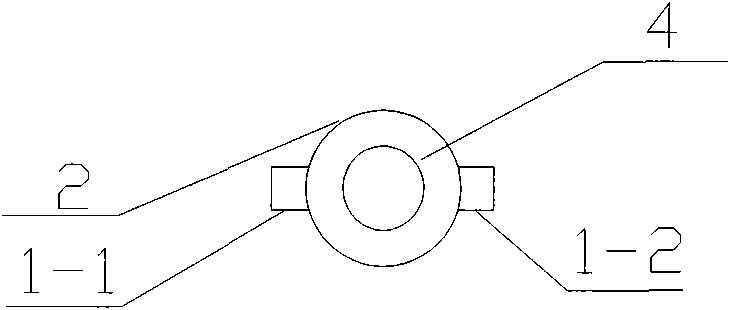

[0027] A method for detecting the integrity of a single-core single-tube inorganic ceramic membrane module, such as figure 1 and figure 2 In the single-core single-tube inorganic ceramic membrane module shown, water enters one end of the upper head 2, and the lower end of the lower head 5 is observed. It is found that the flow rate of the outlet liquid is significantly smaller than the water intake, indicating that the membrane tube is broken, that is to say, the membrane module Incomplete, the root membrane tube needs to be replaced.

Embodiment 2

[0029] The detection method of single-core single-tube inorganic ceramic membrane module, such as figure 1 and figure 2 In the single-core single-tube inorganic ceramic membrane module shown, ethanol is fed into end 2 of the upper head, and the 5 end of the lower head is observed. It is found that the flow rate of ethanol at the outlet is basically the same as the amount of liquid entering, indicating that the membrane tube is not broken.

[0030] The membrane module is filled with ethanol, and soap foam is coated on the upper head 2 and the lower head 5 of the membrane tube of the module, the first permeation test 1-1 enters the air, and the second permeation test 1-2 is sealed, and the air intake pressure is 0.2MPa (the bubble point pressure of the membrane tube is 0.25MPa), observe whether there are bubbles in the sealing ring 3 at the two ends of the membrane module, and find that there is air leakage in the sealing ring 3, indicating that the seal is not good, and the me...

Embodiment 3

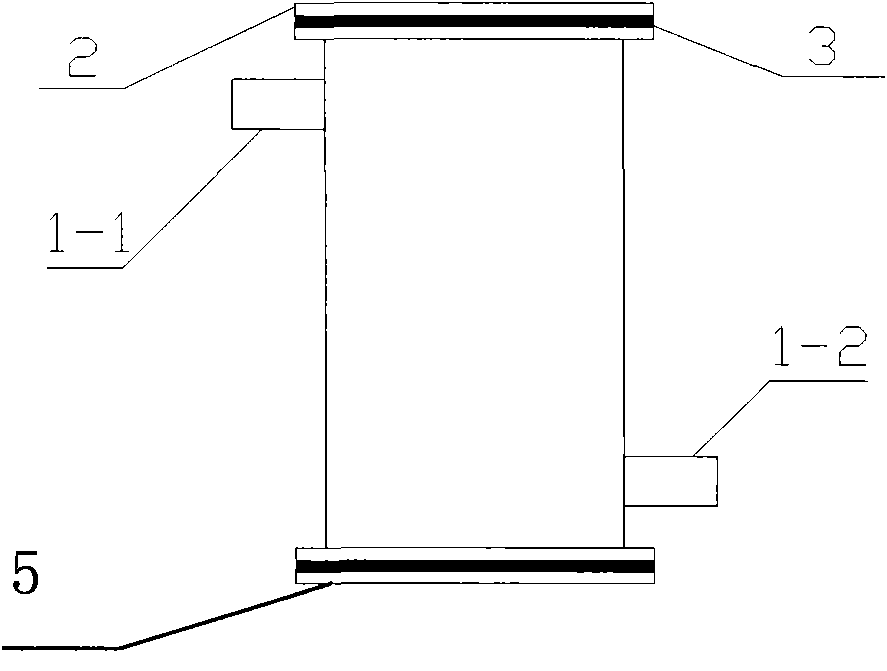

[0032] The detection method of 7-core 7-channel tubular inorganic ceramic membrane module, from such as image 3 and Figure 4 The shown 7-core 7-channel tubular inorganic ceramic membrane module 4 has water entering one end of the upper head 2, observing the lower head 5 of the 7 inorganic ceramic membrane module 4, it is found that the water output of the membrane tube 6 is significantly smaller than that of other membrane tubes If the water output is less, it means that the membrane tube 6 is broken, that is to say, the membrane module is incomplete, and the membrane tube 6 in the inorganic ceramic membrane tube module 4 needs to be replaced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com