Chloroethylene-synthetized series fluidized bed reactor and method

A fluidized bed reactor and synthesis method technology, applied in chemical instruments and methods, chemical recovery, organic chemistry, etc., can solve the problems of low production intensity, poor temperature control, inability to meet the deep conversion of acetylene alone, etc., and achieve the contact effect Good, maintain the effect of acetylene conversion, reduce the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

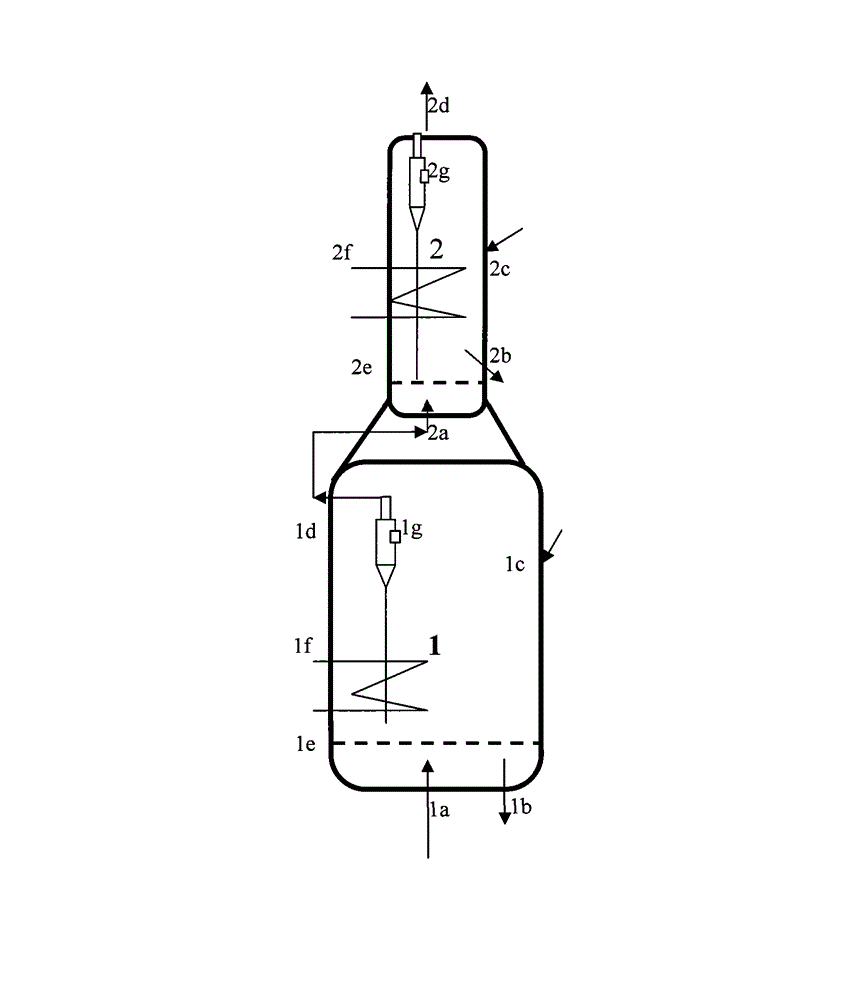

[0038] Fluidized bed (1), (2) is combined to form a complete system (such as figure 1 shown).

[0039] Use HgCl in both fluidized bed (1) and fluidized bed (2) 2 / activated carbon catalyst (HgCl 2 The mass fraction is 10%, the particle size is 0.3mm, and the density is 650kg / m 3 ), passing saturated water with a temperature higher than 120°C into the heat exchange tube 1e to gradually increase the temperature in the fluidized bed (1) to 100-120°C. Then the gas containing hydrogen chloride and acetylene is gradually introduced into the gas through the gas distributor 1e from the gas inlet 1a (other gases are hydrogen, nitrogen and CO 2 , its volume fraction is 8% altogether, the ratio of controlling hydrogen chloride and acetylene is 1.01), and the volume space velocity of acetylene is 20h ~1 , pressure 0.1MPa. The reaction releases heat, and the heat exchange medium in the heat exchange tube 1f is switched to saturated water with a temperature lower than 95°C, and its fl...

Embodiment 2

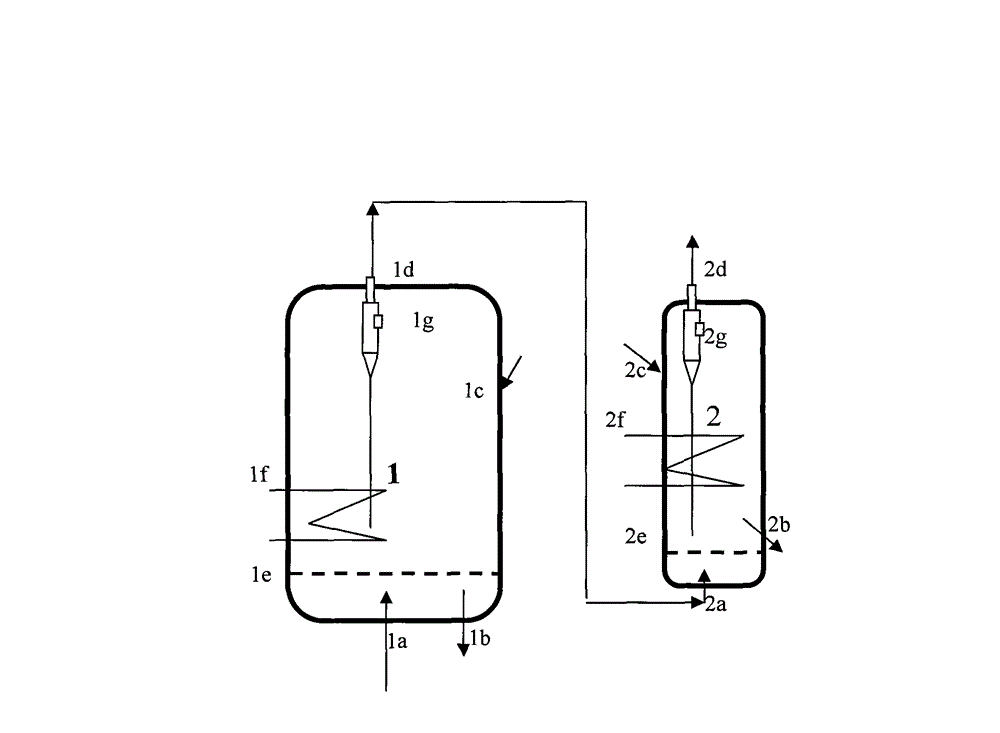

[0042] Fluidized bed (1), (2) is combined to form a complete system (such as figure 2 shown).

[0043] Using HgCl in the fluidized bed (1) 2 / activated carbon catalyst (HgCl 2 The mass fraction is 6%, the particle size is 0.4mm, and the density is 550kg / m 3 ), all use HgCl in the fluidized bed (2) 2 / activated carbon catalyst (HgCl 2 The mass fraction is 14%, the particle size is 0.5mm, and the density is 500kg / m 3 ), passing saturated water with a temperature higher than 120°C into the heat exchange tube 1e to gradually increase the temperature in the fluidized bed (1) to 100-120°C. Then the gas containing hydrogen chloride and acetylene is gradually introduced into the gas through the gas distributor 1e from the gas inlet 1a (other gases are hydrogen, nitrogen and CO 2 , its volume fraction is 8% altogether, and the ratio of controlling hydrogen chloride and acetylene is 1.05). The volumetric space velocity of acetylene is 200h ~1 , pressure 0.4MPa. The reaction ...

Embodiment 3

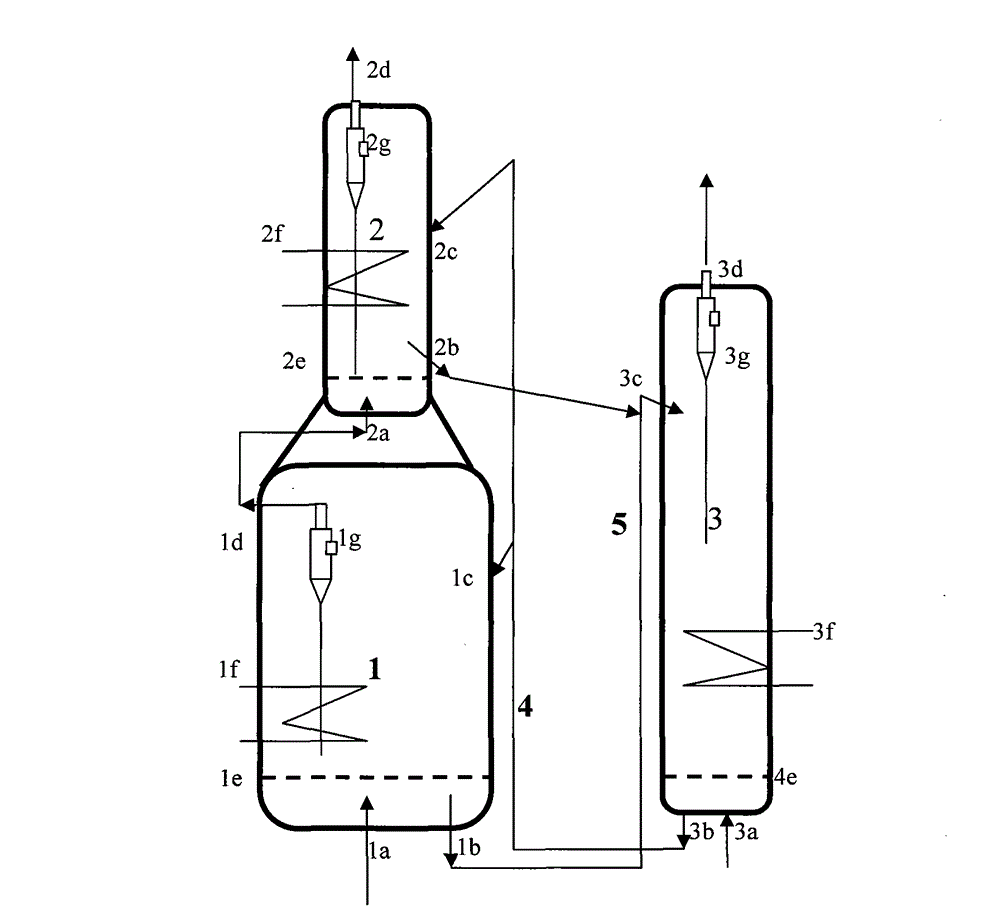

[0046] Use diameter is the fluidized bed (2) of fluidized bed (1) diameter 4 / 5 and the diameter is the fluidized bed (3) of fluidized bed (1) diameter 1 / 2, fluidized bed (1), ( 2) combined with the catalyst regeneration fluidized bed (3) to form a complete system (such as image 3 shown).

[0047] Using CuCl in the fluidized bed (1) 2 / SiO 2 Catalyst (CuCl 2 The mass fraction is 6%, the particle size is 0.2mm, and the density is 1000kg / m 3 ), all use HgCl in the fluidized bed (2) 2 / activated carbon catalyst (HgCl 2 The mass fraction is 14%, the particle size is 0.5mm, and the density is 550kg / m 3 ), passing saturated water with a temperature greater than 180°C into the heat exchange tube 1f to gradually increase the temperature in the fluidized bed (1) to 170-180°C. Then gradually feed the gas containing hydrogen chloride and acetylene (other gases are vinyl chloride (40% by volume) and hydrogen, nitrogen and CO from the gas inlet 1a through the gas distributor 1e 2 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com