Cast special Ni-based high temperature alloy

A high-temperature alloy and special nickel technology, applied in the metallurgical industry, can solve the problems of unsatisfactory performance, deformation, and short service life of alloy materials, and achieve the effect of reasonable chemical composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

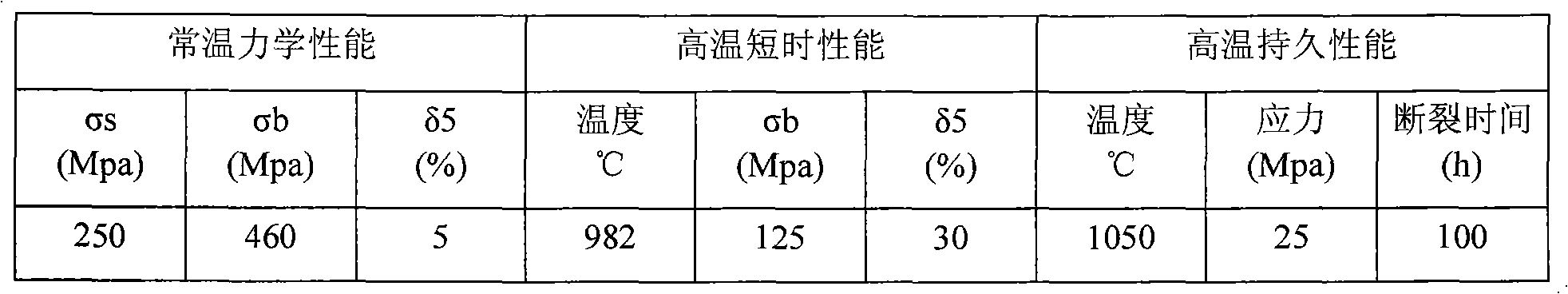

Image

Examples

example 1

[0013] Example 1: Using a 1 ton intermediate frequency induction furnace for smelting, the chemical composition weighed according to the design scheme of the present invention is: C 4.00kg, Si 10.00kg, Mn 8.00kg, P 0.05kg, S 0.05kg, Cr 270.00kg, Ni 470.00kg, W 30.00kg, Co 20.00kg, the rest is Fe and unavoidable trace impurities. Put all the above ingredients into the furnace and melt them, then take samples to analyze the content of the ingredients, and slag and deoxidize. If there is any deviation in the ingredients, it should be adjusted until it is qualified. After the composition is qualified, the molten steel is well deoxidized, and the temperature meets the process requirements, steel preparations can be made.

[0014] According to the needs of users, the alloy of the present invention can be used for centrifugal casting pouring pipes, such as radiant pipes, elbows, etc., or for casting static castings, such as feeding baskets, steering rollers, etc., and can be produced...

example 2

[0015] Example 2: Melting in a 1-ton medium-frequency induction furnace, weighing the chemical composition according to the design of the present invention: C 5.00kg, Si 15.00kg, Mn 12.00kg, P 0.1kg, S 0.1kg, Cr290.00kg, Ni 485.00kg, W 45.00kg, Co 25.00kg, the rest is Fe and unavoidable trace impurities. Put all the above ingredients into the furnace and melt them, then take samples to analyze the content of the ingredients, and slag and deoxidize. If there is any deviation in the ingredients, it should be adjusted until it is qualified. After the composition is qualified, the molten steel is well deoxidized, and the temperature meets the process requirements, steel preparations can be made.

[0016] According to the needs of users, the alloy of the present invention can be used for centrifugal casting pouring pipes, such as radiant pipes, elbows, etc., or for casting static castings, such as feeding baskets, steering rollers, etc., and can be produced by different production ...

example 3

[0017] Example 3: Melting in a 1-ton medium-frequency induction furnace, weighing the chemical composition according to the design of the present invention: C 6.00kg, Si 17.50kg, Mn 15.00kg, P 0.25kg, S 0.25kg, Cr 310.00kg, Ni 500.00kg, W 60.00kg, Co 30.00kg, the rest is Fe and unavoidable trace impurities. Put all the above ingredients into the furnace and melt them, then take samples to analyze the content of the ingredients, and slag and deoxidize. If there is any deviation in the ingredients, it should be adjusted until it is qualified. After the composition is qualified, the molten steel is well deoxidized, and the temperature meets the process requirements, steel preparations can be made.

[0018] According to the needs of users, the alloy of the present invention can be used for centrifugal casting pouring pipes, such as radiant pipes, elbows, etc., or for casting static castings, such as feeding baskets, steering rollers, etc., and can be produced by different producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com