Metal continuous casting method and device used for implementing method

A metal and cold material technology, applied in the field of metallurgy, can solve the problems of difficulty in ensuring uninterrupted feeding of consumable cold materials, and difficulty in rapid replacement, and achieve the effects of accelerating quality exchange, preventing transfer, and cooling uniformly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

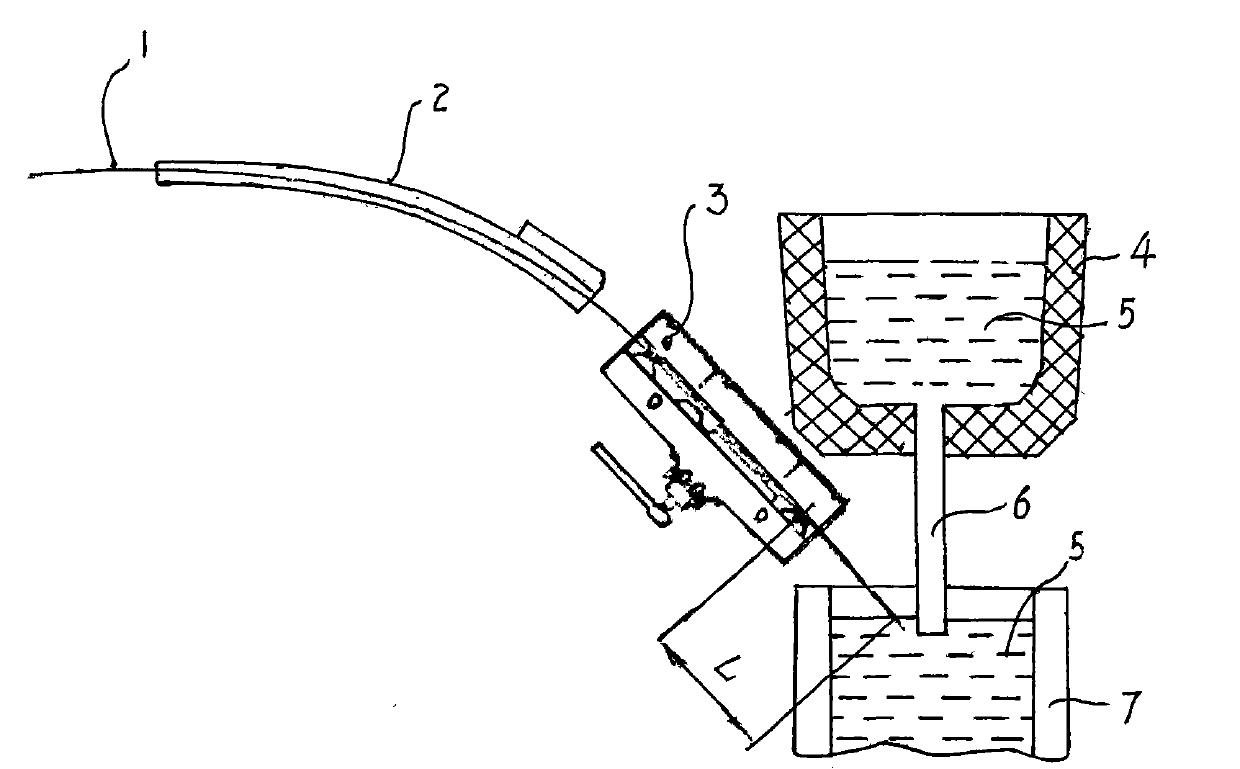

[0080] The device implementing steel and alloy square continuous casting method by this patent is shown in figure 1 . The molten metal 5 enters the crystallizer 7 from the tundish 4 through the submerged ladle 6 .

[0081] This method is used in the continuous casting of molten steel with a carbon content of 0.2% and a liquidus temperature of 1518°C. The cross section of the crystallizer is 250×1550mm, and the continuous casting speed is 0.8-5m / min.

[0082] The consumable cold material is a steel strip with a cross-section of 2.7×100mm. Type conduit and non-contact electromagnetic vibrator are continuously fed into the mold molten steel at a speed of 4.2m / min.

[0083] The carbon content of the steel strip is 0.4%, the liquidus temperature is 1495°C, and the Brinell hardness of the steel strip is 203 scale units.

[0084] With the help of the non-contact electromagnetic vibrator, the cold material can be consumed to generate resonance, the frequency is 93-95Hz, the amplit...

Embodiment 2

[0090] Continuous casting steel is used, the steel contains 0.40% carbon, and the initial casting velocity is 0.43m / min. During the continuous casting process, the steel strip is continuously fed into the crystallizer (trough) (diameter φ530mm), (section 3×80mm), the feeding speed is 4.1m / min, and the carbon content of the steel strip is 0.35%. Under the action of a non-contact electromagnetic vibrator, a resonance is excited in the cold steel strip, with a frequency of 95-100HZ and a wavelength of 540mm.

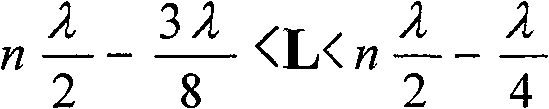

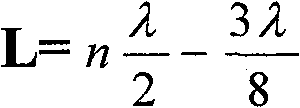

[0091] The distance L from the axis line of the lower roller of the electromagnetic vibrator to the surface of the molten metal in the crystallizer shall satisfy the following formula (n=2):

[0092] L = 2 λ 2 - 3 λ 8 = 2 / 2 × 540 - 3 / ...

Embodiment 3

[0094] Continuous casting steel is used, the carbon content of the steel is 0.40%, and the casting speed is 0.43m / min. During the continuous casting process, the cold steel strip (section 3×80mm) is continuously fed to the crystallizer (trough) (diameter φ530mm), the feeding speed is 4.1m / min, and the carbon content of the steel strip is 0.35%. Under the action of the non-contact electromagnetic vibrator, the resonance is excited in the cold steel strip, the frequency is 95-100HZ, the wavelength is 540mm, and the amplitude is 4.0-5.0mm.

[0095] The distance L from the axis line of the lower roller of the electromagnetic vibrator to the surface of the molten metal in the crystallizer shall satisfy the following formula (n=4):

[0096] L = 4 λ 2 - 3 λ 8 = 4 / 2 × 540 - ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com