Glassy carbon electrode (GCE) modified by conductive copolymer carbon nanotube composite, preparation method thereof and method for removing perchlorat from water

A glassy carbon electrode, carbon nanotube technology, applied in electrodes, chemical instruments and methods, electrolysis process, etc., can solve problems such as difficult processing and insignificant effects, achieve no secondary pollution, convenient operation, and increase electrode size. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Disperse the carbon nanotubes in DMF and ultrasonically disperse them for 10 hours;

[0023] 2) Take out 2 microliters of carbon nanotubes dispersed in step 1) with a micro-syringe and drop them on the surface of a clean glassy carbon electrode, let stand for 24 hours, and air-dry for later use;

[0024] 3) The three electrodes used in the electrolytic cell are set, and the three electrodes are composed of a modified glassy carbon working electrode, a platinum counter electrode and a saturated calomel reference electrode;

[0025] 4) Prepare a mixed solution of aniline, o-aminophenol and hydrochloric acid, wherein the concentration of aniline is 0.01mol dm -3 , the concentration of o-aminophenol is 1.0mmol dm -3 , the concentration of hydrochloric acid is 0.5mol dm -3 ;

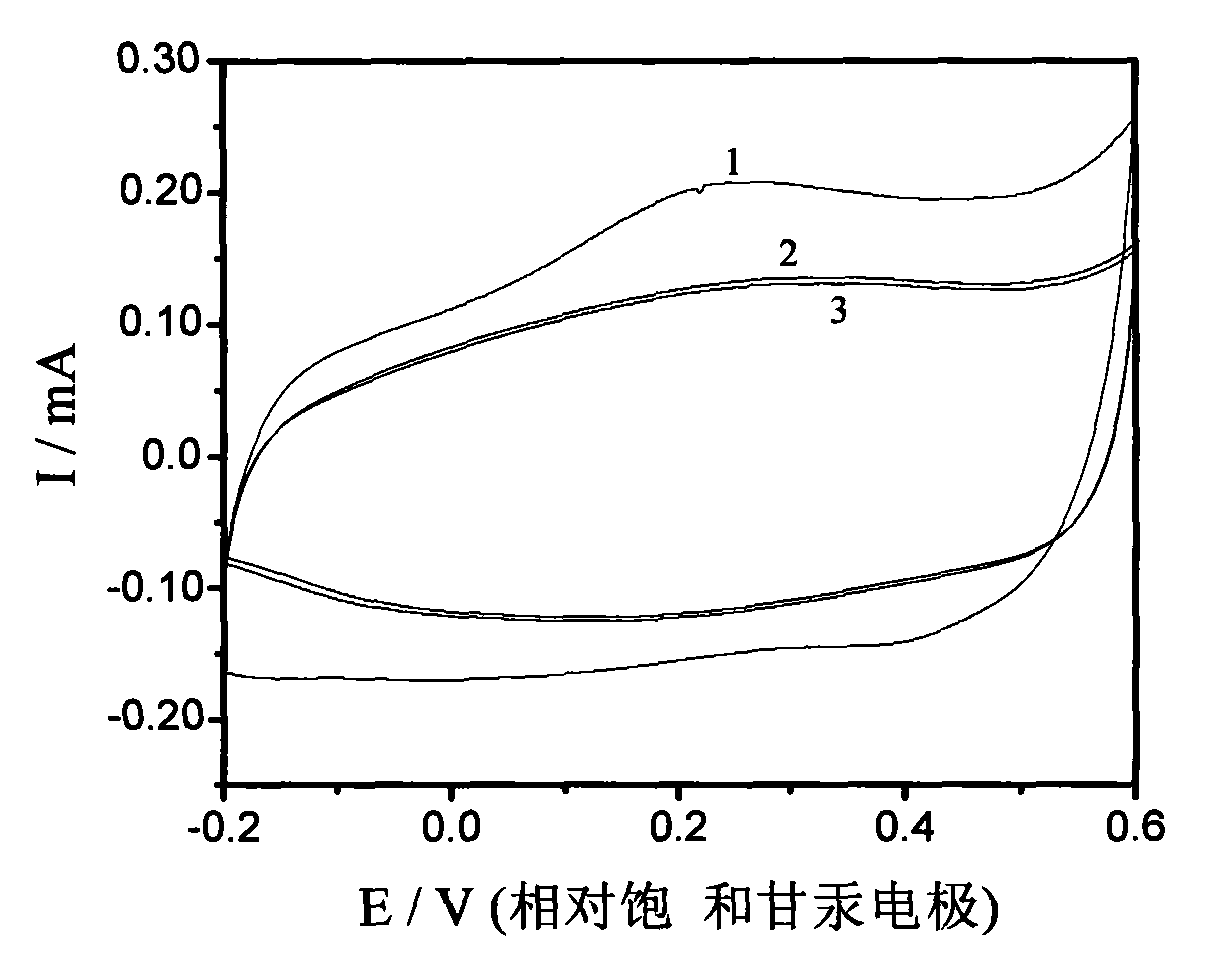

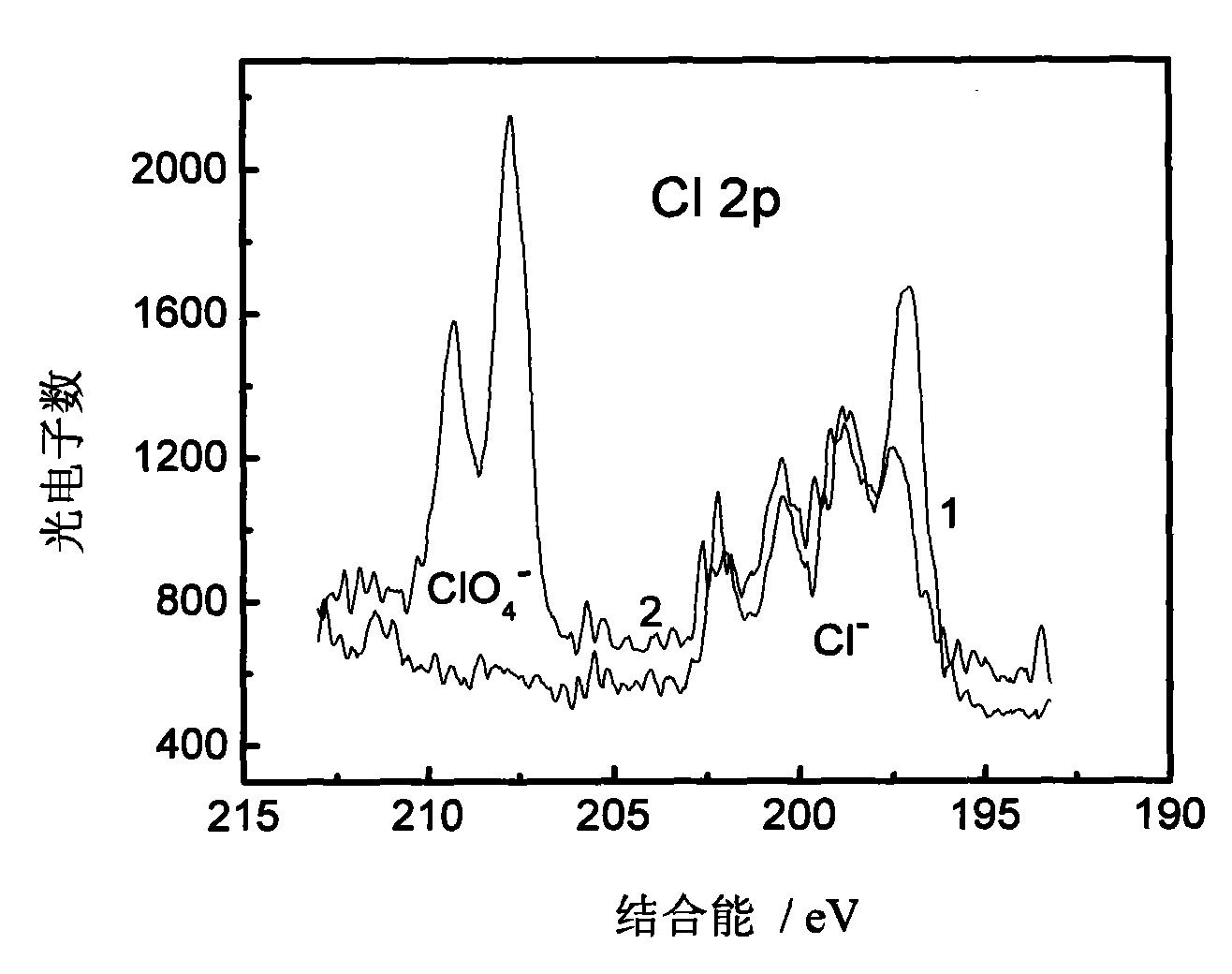

[0026] 5) Put the three electrodes of step 3) into the prepared mixed solution to form a three-electrode system electrolytic cell, perform electrolysis with a constant potential method, the elect...

Embodiment 2

[0029] 1) Disperse the carbon nanotubes in DMF and ultrasonically disperse them for 24 hours;

[0030] 2) Take out 10 microliters of carbon nanotubes dispersed in step 1) with a micro-syringe and drop them on the surface of a clean glassy carbon electrode, let stand for 36 hours, and air-dry for later use;

[0031] 3) The three electrodes used in the electrolytic cell are set, and the three electrodes are composed of a modified glassy carbon working electrode, a platinum counter electrode and a saturated calomel reference electrode;

[0032] 4) Prepare a mixed solution of aniline, o-aminophenol and hydrochloric acid, wherein the concentration of aniline is 2.0mol dm -3 , the concentration of o-aminophenol is 20mmol dm -3 , the concentration of hydrochloric acid is 6.0mol dm -3 ;

[0033] 5) Put the three electrodes of step 3) into the prepared mixed solution to form a three-electrode system electrolytic cell, perform electrolysis with a constant potential method, the electr...

Embodiment 3

[0036] 1) Disperse the carbon nanotubes in DMF and ultrasonically disperse them for 24 hours;

[0037] 2) Take out 10 microliters of carbon nanotubes dispersed in step 1) with a micro-syringe and drop them on the surface of a clean glassy carbon electrode, let stand for 30 hours, and air-dry for later use;

[0038] 3) The three electrodes used in the electrolytic cell are set, and the three electrodes are composed of a modified glassy carbon working electrode, a platinum counter electrode and a saturated calomel reference electrode;

[0039] 4) Prepare a mixed solution of aniline, o-aminophenol and hydrochloric acid, wherein the concentration of aniline is 1.0mol dm -3 , the concentration of o-aminophenol is 5.0mmol dm -3 , the concentration of hydrochloric acid is 3.0mol dm -3 ;

[0040] 5) Put the three electrodes of step 3) into the prepared mixed solution to form a three-electrode system electrolytic cell, perform electrolysis with a constant potential method, the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com