Processing method for recycling electroplating concentrated control zone electroplating waste water resource

A technology of electroplating wastewater and treatment method, which is applied in the fields of metallurgical wastewater treatment, chemical instruments and methods, flotation water/sewage treatment, etc., can solve the problems of electroplating wastewater that cannot stably meet discharge standards, high cost, and sludge becoming hazardous waste. , to achieve the effect of large promotion and application value, large economic value, and reduced recycling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

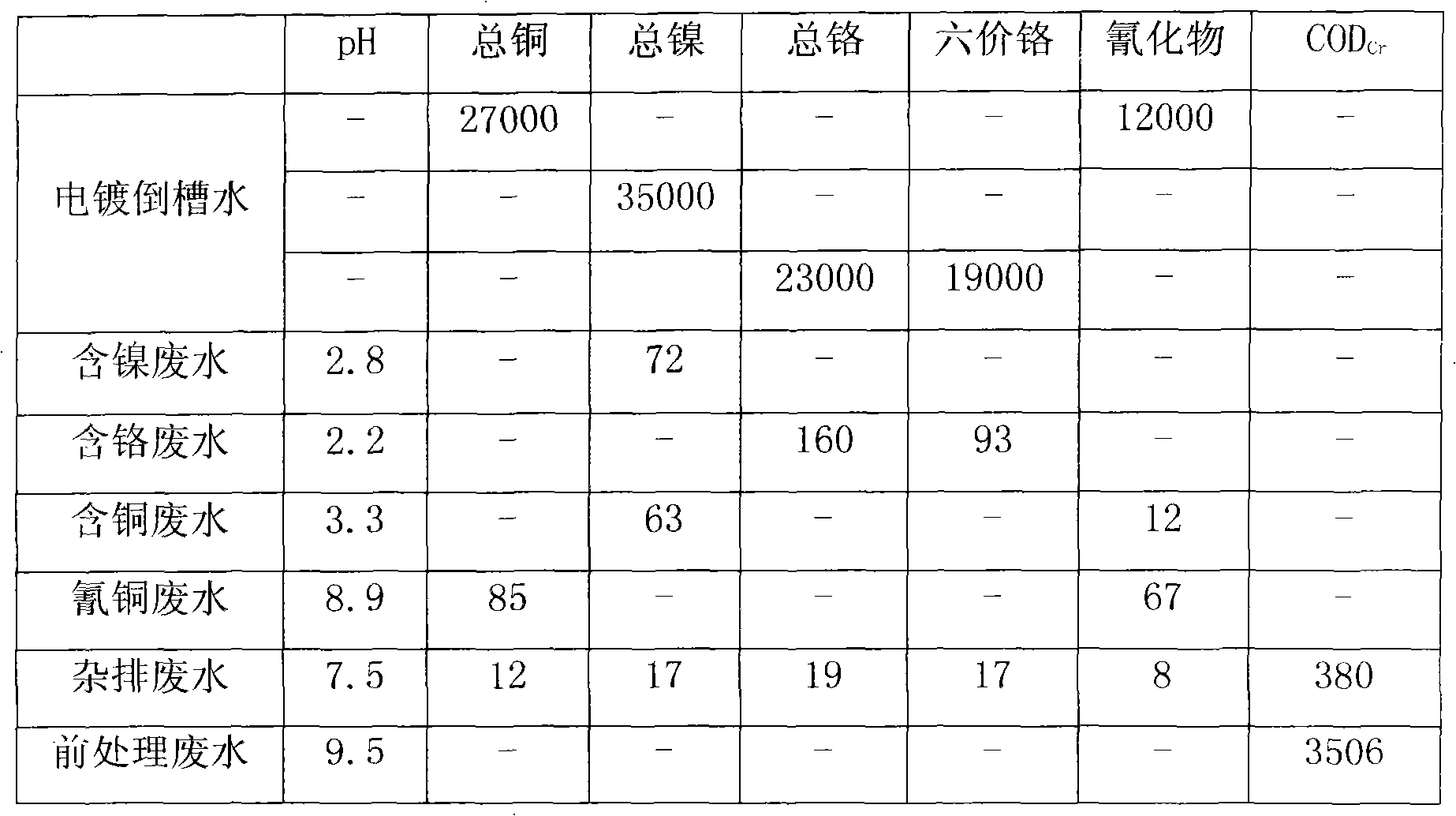

[0023] The total amount of electroplating wastewater in the electroplating centralized control area is 3000m 3 , the influent water quality indicators are shown in the following table 1:

[0024] Table 1 Water Quality and Quantity of Electroplating Wastewater Unit: mg / L

[0025]

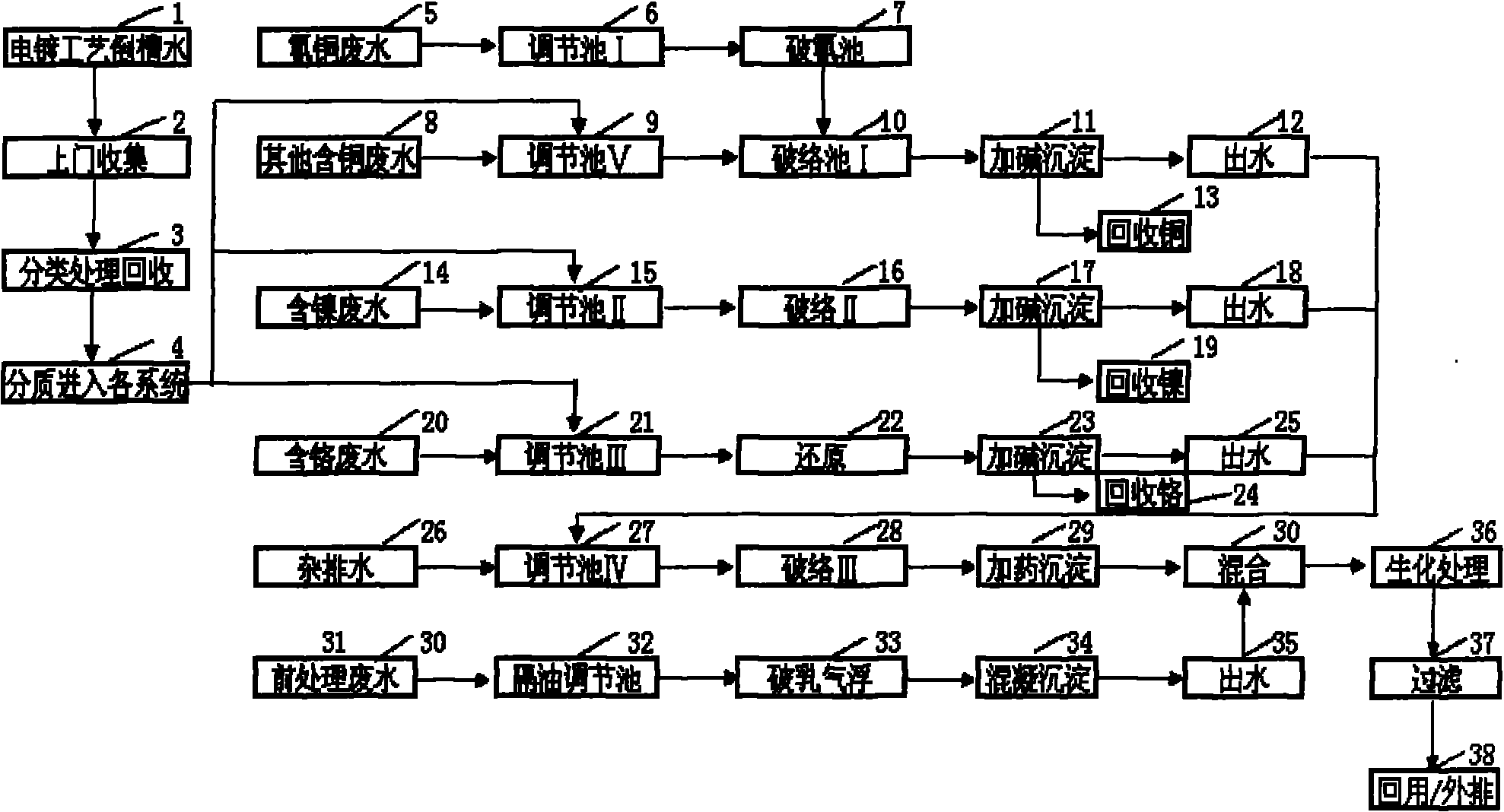

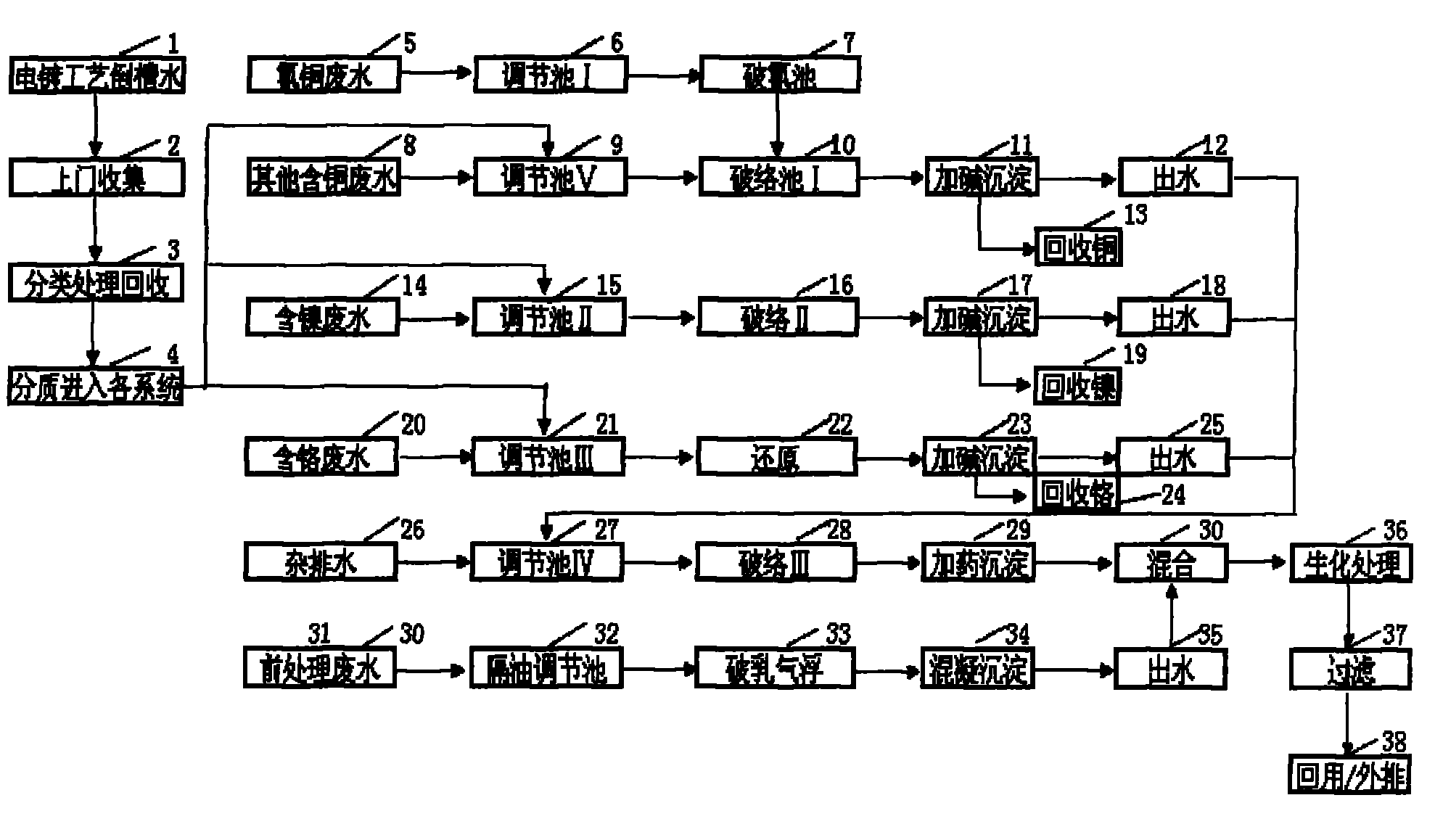

[0026] The above wastewater is used as figure 1 The processing method shown, the steps are as follows:

[0027] a) The electroplating process poured tank water 1 of each electroplating factory is collected in buckets 2 respectively, and then classified and recovered 3, that is, pretreatment: mainly adopt chemical methods, adjust the optimal pH according to the properties of various types of wastewater to make The heavy metals are completely precipitated and collected by adding alkali: calcium hydroxide to form a precipitate. The pH value is controlled at 7 when copper is recovered, the pH value is controlled at 9.5 when nickel is recovered, and the pH value is controlled at 5.5 when chromium is ...

Embodiment 2

[0040] The total amount of electroplating wastewater in the electroplating centralized control area is 3000m 3 , the influent water quality indicators are shown in Table 2 below:

[0041] Table 2 Water Quality and Quantity of Electroplating Wastewater Unit: mg / L

[0042]

[0043] The above wastewater is used as figure 1 The processing method shown, the steps are as follows:

[0044] a) The electroplating process poured tank water 1 of each electroplating factory is collected in buckets 2 respectively, and then classified and recovered 3, that is, pretreatment is carried out, mainly using chemical methods, and adjusting the optimal pH according to the properties of various types of wastewater. The heavy metals are completely precipitated and collected by adding alkali: calcium hydroxide to form a precipitate. The pH value is controlled at 7 when copper is recovered, the pH value is controlled at 9.5 when nickel is recovered, and the pH value is controlled at 5.5 when chrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com