Difenoconazole emulsible powder

A technology of difenoconazole and emulsifier, applied in the directions of biocides, fungicides, biocides, etc., can solve the problems of poor stability of suspending agents, unsuitable storage, high organic solvent content, and high cost of raw materials, and achieve poor storage stability. , the effect of less environmental pollution and high cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1 prepares 25% difenoconazole emulsifiable powder

[0015] (1) The formula is shown in Table 1

[0016] Table 1

[0017] components

raw material name

Dosage, mass fraction (%)

Difenoconazole

Content 95% of the original drug

25

Solvent oil

5

Emulsifier

Difenoconazole Emulsifier

10

Dispersant

Sodium lignosulfonate

3

1

suspending agent

1

carrier

① Clay

②white carbon black

4

51 (make up to 100)

[0018] (2) Preparation

[0019] Weigh each component according to the formula amount in Table 1, then put it into a container, stir and mix evenly, pulverize with a jet mill, control the final particle size to be 45 μm, and pack to obtain 25% difenoconazole emulsifiable powder of the present invention.

Embodiment 2

[0020] Embodiment 2 prepares 30% difenoconazole emulsifiable powder

[0021] (1) The formula is shown in Table 2

[0022] Table 2

[0023] components

raw material name

Dosage, mass fraction (%)

Difenoconazole

Content 95% of the original drug

30

4

Emulsifier

①Agricultural Milk 500

②Agricultural Milk 600

③Agricultural milk 700

3

5

2

Dispersant

Dispersant MF

5

Wetting agent JFC

1

suspending agent

1.5

carrier

②white carbon black

10

38.5 (make up to 100)

[0024] (2) Preparation

[0025] Weigh each component according to the formula amount in Table 2, then put it into a container, stir and mix evenly, pulverize with a jet mill, control the final particle size to be 45 μm, and pack to obtain the 30% difenoconazole emulsifiab...

Embodiment 3

[0026] Embodiment 3 preparation 5% difenoconazole emulsifiable powder

[0027] (1) The formula is shown in Table 3

[0028] table 3

[0029] components

raw material name

Dosage, mass fraction (%)

Difenoconazole

Content 95% of the original drug

5

solvent

Solvent oil

2

Emulsifier

Difenoconazole Emulsifier

4

Dispersant

Dispersant NNO

2

0.5

suspending agent

industrial starch

4

carrier

①white carbon black

25

57.5 (make up to 100)

[0030] (3) Preparation

[0031] Weigh each component according to the formula amount in Table 3, then put it into a container, stir and mix evenly, pulverize with a jet mill, control the final particle size to be 45 μm, and pack to obtain 5% difenoconazole emulsifiable powder of the present invention.

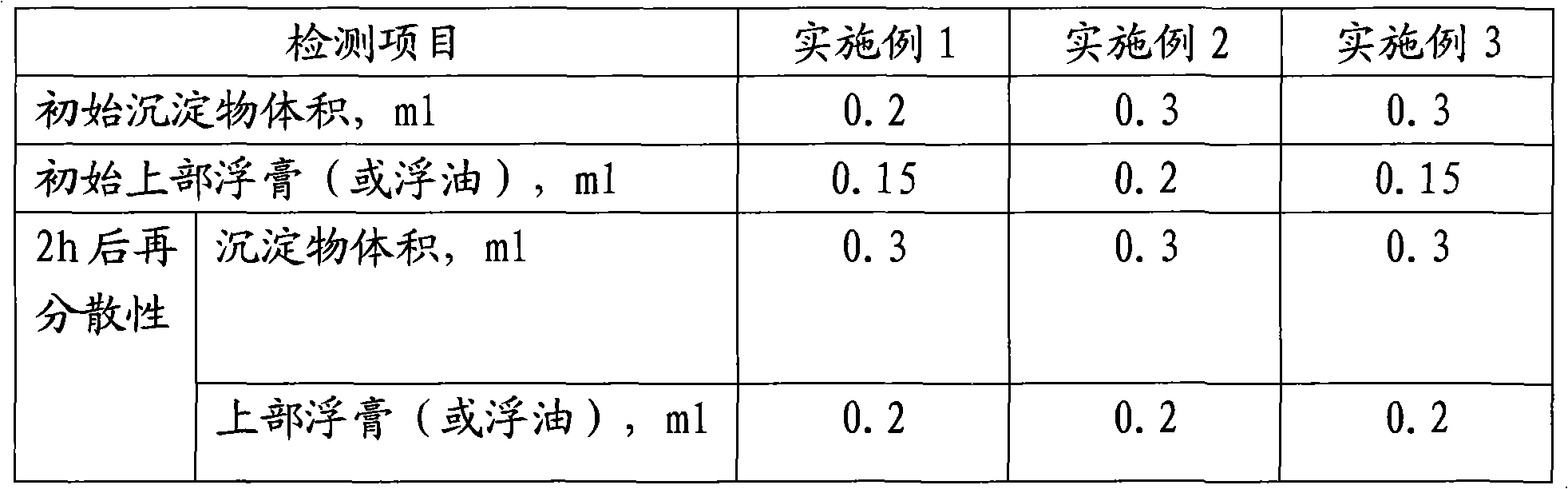

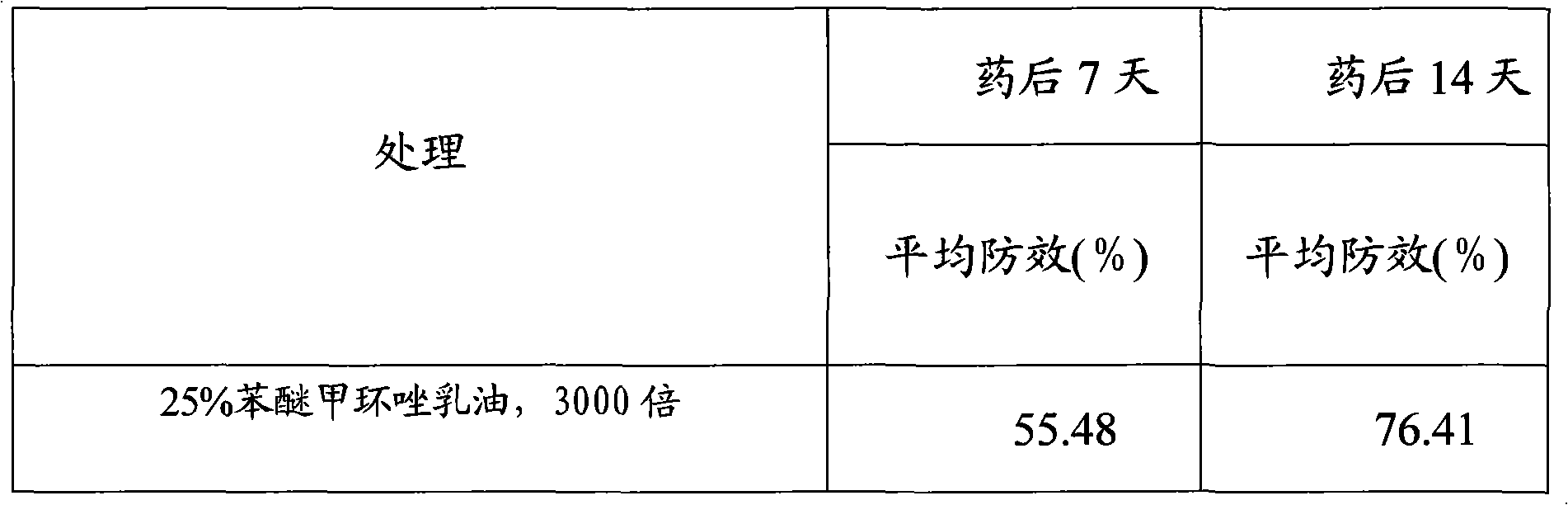

[0032] The difenoco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com