Radiating member, circuit board using the member, electronic part module, and method for manufacturing the module

A technology for electronic components and circuit substrates, which is applied to printed circuit components, laminated printed circuit boards, semiconductor/solid-state device components, etc., and can solve problems such as difficulty in achieving high heat dissipation, difficulty in ensuring thickness, and increased development costs , to achieve the effect of light weight, improved degree of freedom, and high degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] In Example 1, in the heat dissipation structure capable of efficiently dissipating the heat generated by the LED module, the heat dissipation effect of the heat dissipation member using different materials was confirmed.

[0098] Generally, the maximum temperature that an LED can use is determined by the surface temperature of the LED chip (junction temperature: Tj), but the Tj temperature cannot actually be measured directly.

[0099] Here, the LED has a characteristic that the forward voltage (Vf) decreases when the junction temperature increases. Therefore, the tendency to change the junction temperature is measured by measuring the forward voltage (Vf).

[0100] The junction temperature can be calculated from the characteristics of the LED voltage and the junction temperature obtained by the preliminary test. The junction temperature can be calculated from this result with constant accuracy.

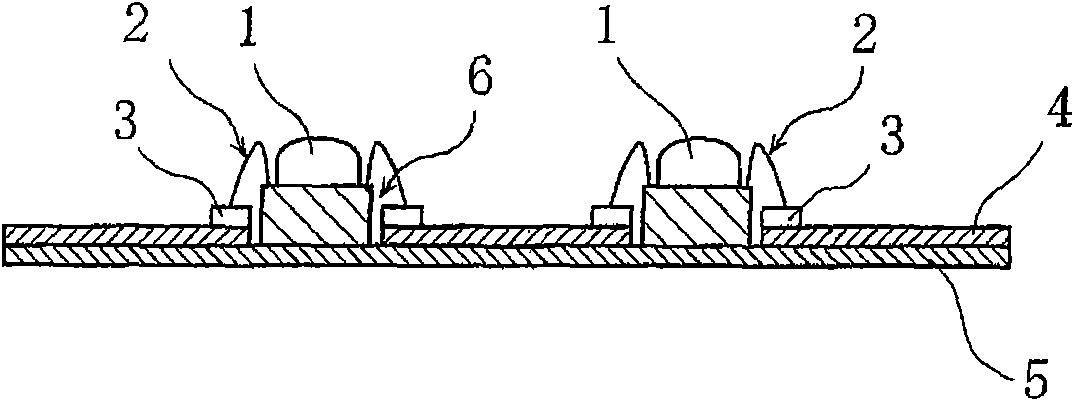

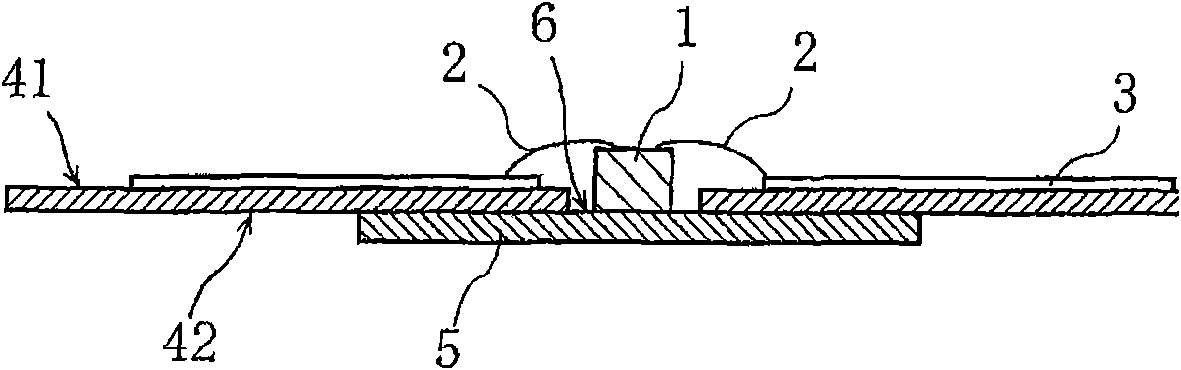

[0101] The LED module 1 used in this embodiment is composed of a base s...

Embodiment 2

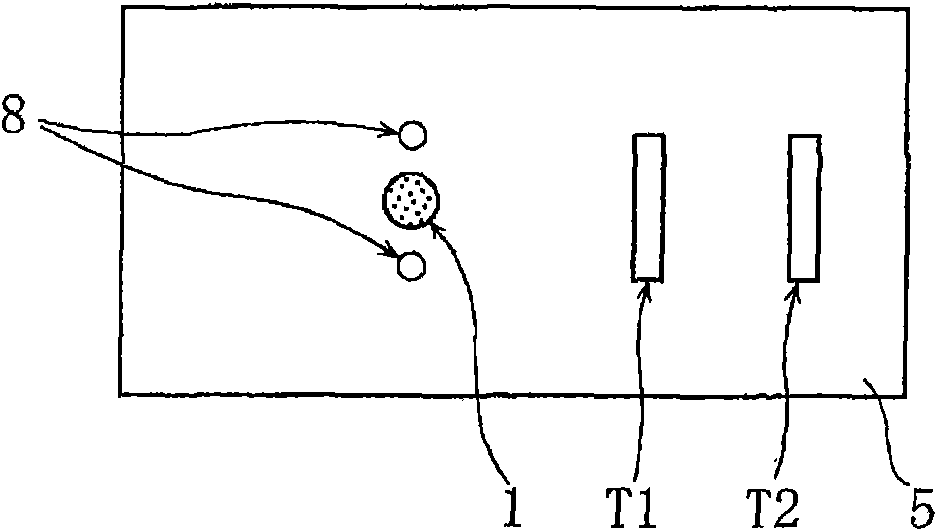

[0119] In this example, a temperature comparison test of graphite sheets with different areas was carried out. like Figure 8 As shown, in this embodiment, seven LED modules 1 used in Embodiment 1 are mounted on the substrate 4 . Silicon grease (G-747) was applied between the heat dissipation member 5 and the LED module 1 . By applying the silicone grease, the contact area can be increased, so that a higher heat dissipation effect can be achieved. The specifications of the heat dissipation member 5 are as follows, and the other structure thereof is the same as that of the first embodiment. Therefore, the bulk density of the graphite flakes is all 2.0Mg / m 3 , Thickness D is 1.5mm.

[0120] "Specifications of Heat Dissipating Components"

[0121] Manufacturer name: Toyo Carbon Co., Ltd.

[0122] Model: PF-150UHP

[0123] Thickness: 1.5mm

[0124] shape etc:

experiment example 1

[0125] Experimental example 1 (with an area of 430cm 2 The square of , in addition, has a mass of 129g, so the heat capacity is 45.15J / K)

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com