Transparent electrically conductive film and touch panel including the same

A technology of transparent conductive film and conductive polymer, which is applied to the conductive layer, non-metallic conductor, organic material conductor, etc. , Writing durability deterioration and other problems, to achieve the effect of improving self-healing, suppressing cracks, and improving writing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

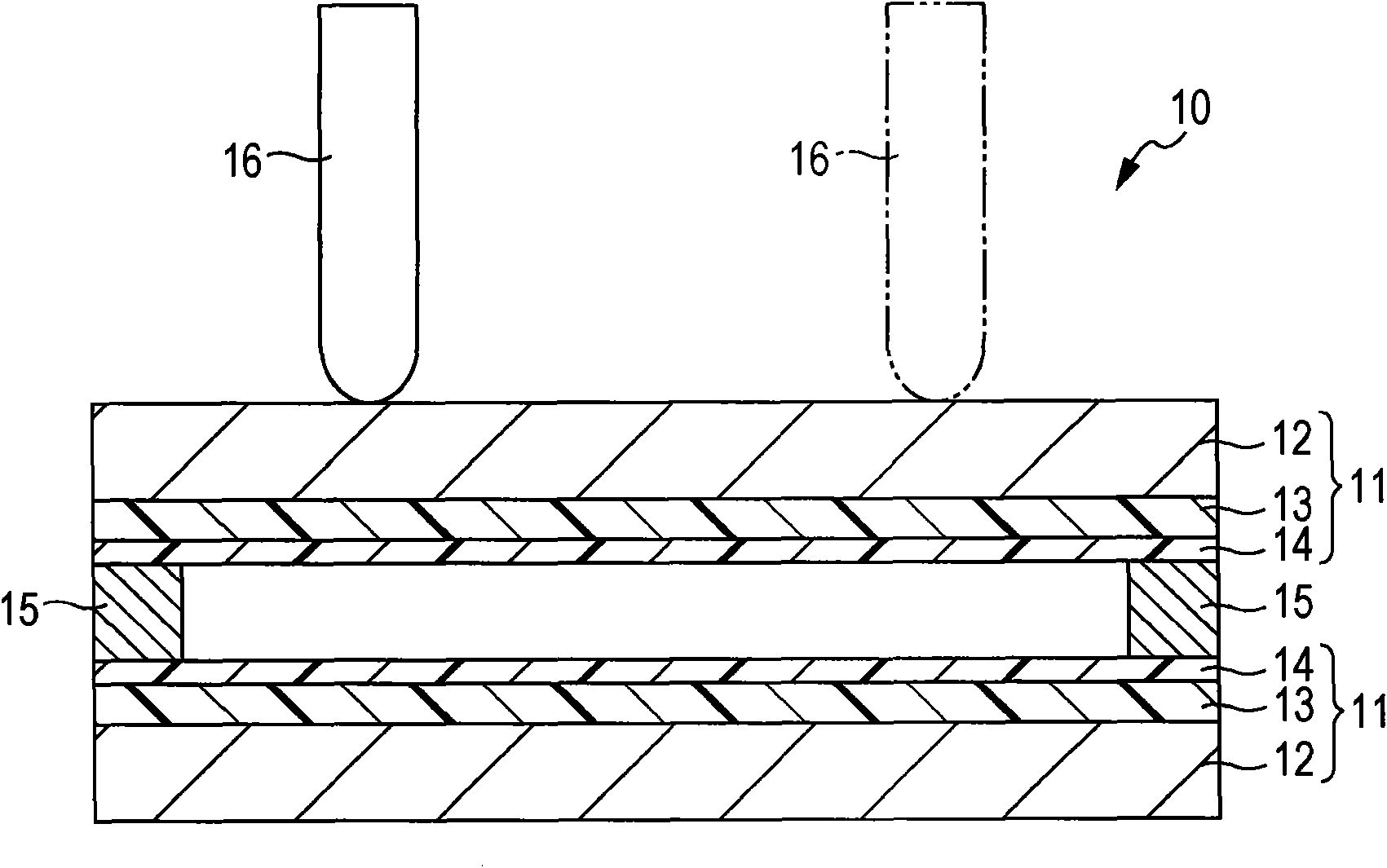

[0103] Hereinafter, the above-mentioned embodiment will be described more concretely with reference to production examples, examples, and comparative examples, but the present invention is not limited by the scope of these examples. The Martens hardness, haze value, total light transmittance, surface resistivity, and writing durability in each example were measured by the following methods. In addition, the part in each example represents a weight part.

[0104] (1) Martens Hardness

[0105] On the PET film as the transparent substrate 12, the curable composition used to form the soft resin layer is coated with a dry film thickness of 30 μm and cured to form the soft resin layer 13, which is tested by ultramicrohardness The Martens hardness (N / mm 2 ). The measurement conditions are temperature 20° C., relative humidity 50%, maximum load 2 mN, first creep: 5 seconds, second creep: 5 seconds.

[0106] (2) Haze value

[0107] Using NDH-2000 produced by Nippon Densho Kogyo Co...

manufacture example 1-1

[0118] [Manufacturing Example 1-1, Preparation of Curable Coating Liquid (F-1) for Forming Soft Resin Layer]

[0119] 2.1 parts of hexamethylene diisocyanate [produced by Mitsui Takeda Chemical Co., Ltd., trade name: TAKENATE 700] and polycaprolactone-modified hydroxyethyl ester [produced by Daicel Chemical Industry Co., Ltd., trade name: PLACCEL FA10L, poly Repeating number of caprolactone units = 10] 90 parts of amine acrylate composed of 97.9 parts, phthalic acid monohydroxyethyl methacrylate [manufactured by Toagosei Co., Ltd., trade name: M-5400] 6.8 parts, 1- 3 parts of hydroxycyclohexyl phenylacetone, 0.2 parts of a surface conditioner [manufactured by BYK Chemicals, trade name "BYK-381"], and 100 parts of methyl ethyl ketone were mixed to prepare a curable coating for forming a soft resin layer. Liquid (F-1).

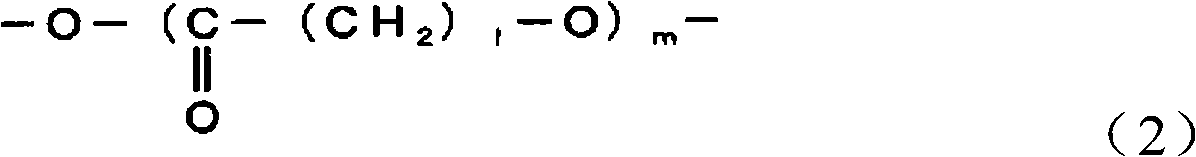

[0120] The curable coating solution for forming the soft resin layer contained 80% by weight of the repeating unit represented by the above chemical formula (2...

manufacture example 1-2

[0121] [Manufacturing Example 1-2, Preparation of Curable Coating Liquid (F-2) for Forming Soft Resin Layer]

[0122]20.5 parts of isocyanurate-modified acrylate amine ester [Mitsui Takeda Chemical Co., Ltd., trade name: TAKENATE D-170] from hexamethylene diisocyanate, and polycaprolactone-modified hydroxyethyl ester [Daicel Produced by Chemical Industry Co., Ltd., product name: PLACCEL FA5, repeating number of polycaprolactone units = 5] 90 parts of acrylate amine ester composed of 79.5 parts, 2-hydroxypropyl acrylate [manufactured by Osaka Organic Chemical Industry Co., Ltd., commercial product Name: 6.8 parts of HPA], 3 parts of 1-hydroxycyclohexyl phenylacetone, 0.2 parts of a surface conditioner (manufactured by BYK Chemicals, trade name "BYK-381") and 100 parts of methyl ethyl ketone are mixed to prepare for Curable coating solution (F-2) for forming a soft resin layer.

[0123] The curable coating solution for forming the soft resin layer contained 57% by weight of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com