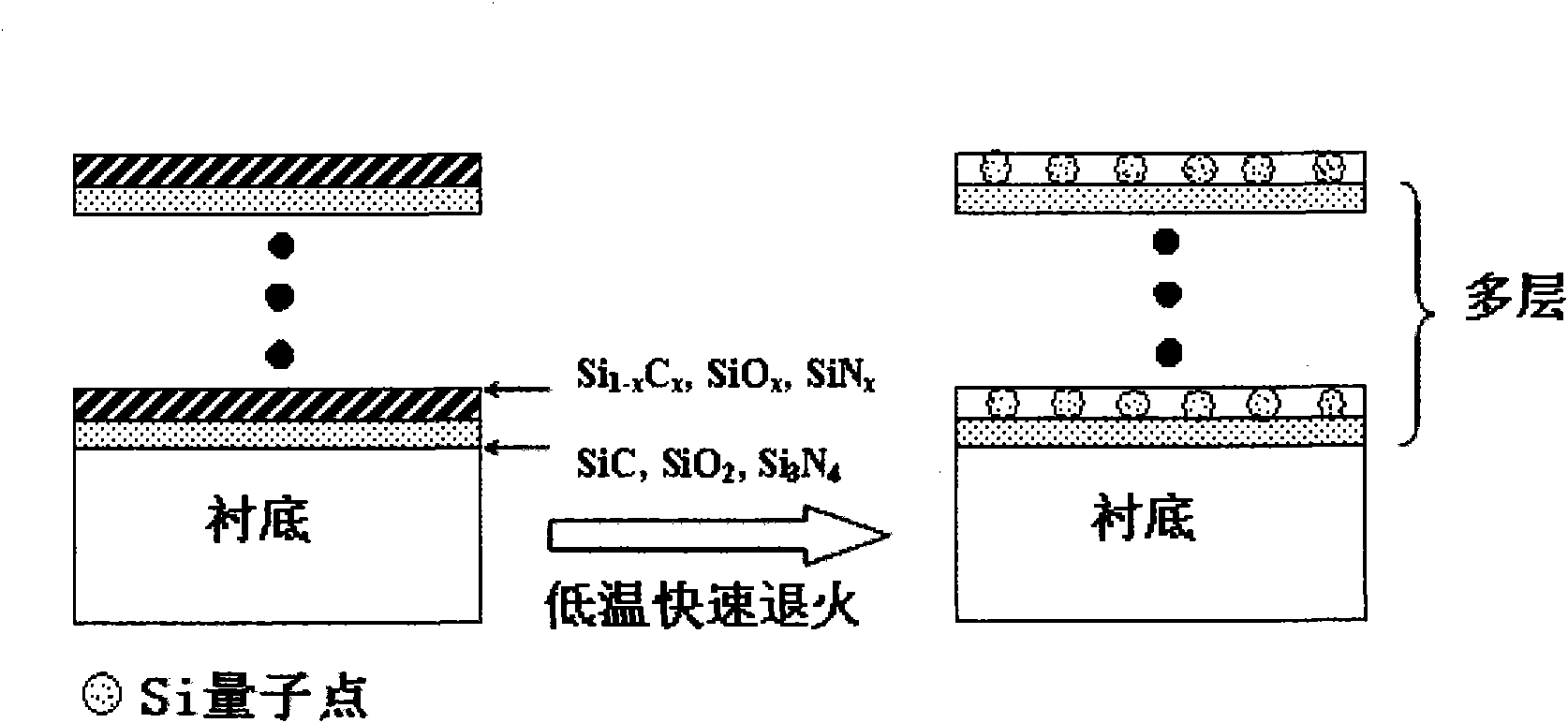

Low-temperature growth method of silicon quantum dots for solar battery

A technology of silicon quantum dots and solar cells, applied in circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of increased process complexity and production costs, poor controllability and repeatability of the growth process, thermal damage of solar cells, etc. problem, to achieve the effect of good process controllability and repeatability, good uniformity and fast deposition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Using radio frequency plasma enhanced chemical vapor deposition technology, the substrate chooses a Si sheet with a diameter of 4 inches and a thickness of 1mm, and alternately grows 2nm thick Si 3 N 4 Dielectric layer and 2nm Si-rich SiN x layer, Si 3 N 4 / SiN x The deposition period is 40. Deposition conditions: RF frequency 13.56MHz, RF power 60W, background vacuum up to 1×10 -4 Pa, the reaction gas is N 2 Diluted SiH 4 (gas volume N 2 : SiH 4 =1:1) and NH 3 , the working pressure is 10Pa, the deposition temperature is 300℃, and the deposited Si 3 N 4 When the medium layer is used, the reaction gas flow rate is N 2 Diluted SiH 4 30sccm (standard condition milliliter per minute), NH 3 30sccm, deposition rate 0.2nm / s, deposition of Si-rich SiN x layer, the reaction gas flow rate is N 2 Diluted SiH 4 100sccm, NH 3 The deposition rate is 30sccm, and the deposition rate is 0.25nm / s; the film sample is placed in a rapid photothermal treatment furnace for ...

Embodiment 2

[0017] Microwave plasma-enhanced chemical vapor deposition technology is adopted, and the substrate is selected as a 20cm×20cm, 3mm thick ordinary glass sheet, and 2nm thick SiO is alternately grown 2 Dielectric layer and 4nm Si-rich SiN x layer, SiO 2 / SiN x The deposition period is 50. Deposition conditions: RF frequency 13.56MHz, RF power 60W, background vacuum up to 1×10 -4 Pa, the reaction gas is N 2 Diluted SiH 4 (gas volume N 2 : SiH 4 =1:1) and O 2 , the working pressure is 10Pa, the deposition temperature is 300℃, and the SiO 2 When the medium layer is used, the reaction gas flow rate is N 2 Diluted SiH 4 For 30sccm (standard condition milliliters per minute), O 2 30sccm, deposition rate 0.2nm / s, deposition of Si-rich SiN x layer, the reaction gas flow rate is N 2 Diluted SiH 4 100sccm, NH 3 The deposition rate is 30 sccm, and the deposition rate is 0.25nm / s; the thin film sample is placed in a rapid photothermal treatment furnace for annealing treatmen...

Embodiment 3

[0019]Electron cyclotron resonance plasma-enhanced chemical vapor deposition technology is used, the substrate is 20cm×30cm, 2mm thick stainless steel sheet, and 3nm thick SiC dielectric layer and 6nm Si-rich SiN are alternately grown x layer, SiC / SiN x The deposition period is 60. Deposition conditions: RF frequency 13.56MHz, RF power 60W, background vacuum up to 1×10 -4 Pa, the reaction gas is N 2 Diluted SiH 4 (gas volume N 2 : SiH 4 =1:1) and CH 4 , the working pressure is 10Pa, the deposition temperature is 300℃, when depositing the SiC dielectric layer, the reaction gas flow rate is N 2 Diluted SiH 4 30sccm (standard condition milliliters per minute), CH 4 30sccm, deposition rate 0.2nm / s, deposition of Si-rich SiN x layer, the reaction gas flow rate is N 2 Diluted SiH 4 100sccm, NH 3 The deposition rate is 30sccm, and the deposition rate is 0.25nm / s; the film sample is placed in a rapid photothermal treatment furnace for annealing treatment, using a halogen t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com