Green phosphor powder excited by vacuum ultraviolet and low-voltage cathode ray and preparation method thereof

A green phosphor and cathode ray technology, applied in the field of phosphor materials, can solve problems such as the influence of afterglow time, poor stability of PDP screen picture quality, and short afterglow time, and achieve low cost, easy operation, and strong green light emission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh lanthanum trioxide (La 2 o 3 )0.5404g, terbium oxide (Tb 4 o 7 ) 0.0031g, calcium carbonate (CaCO 3 ) 1.0009g, sodium carbonate (Na 2 CO 3 ) 0.1943g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 1.1504g, ammonium fluoride (NH 4 F) 0.1729g, fully ground in an agate mortar and mixed evenly, sintered in a carbon monoxide atmosphere at 1050°C for 4 hours, cooled to room temperature, and the sample was taken out and ground to finally obtain the product.

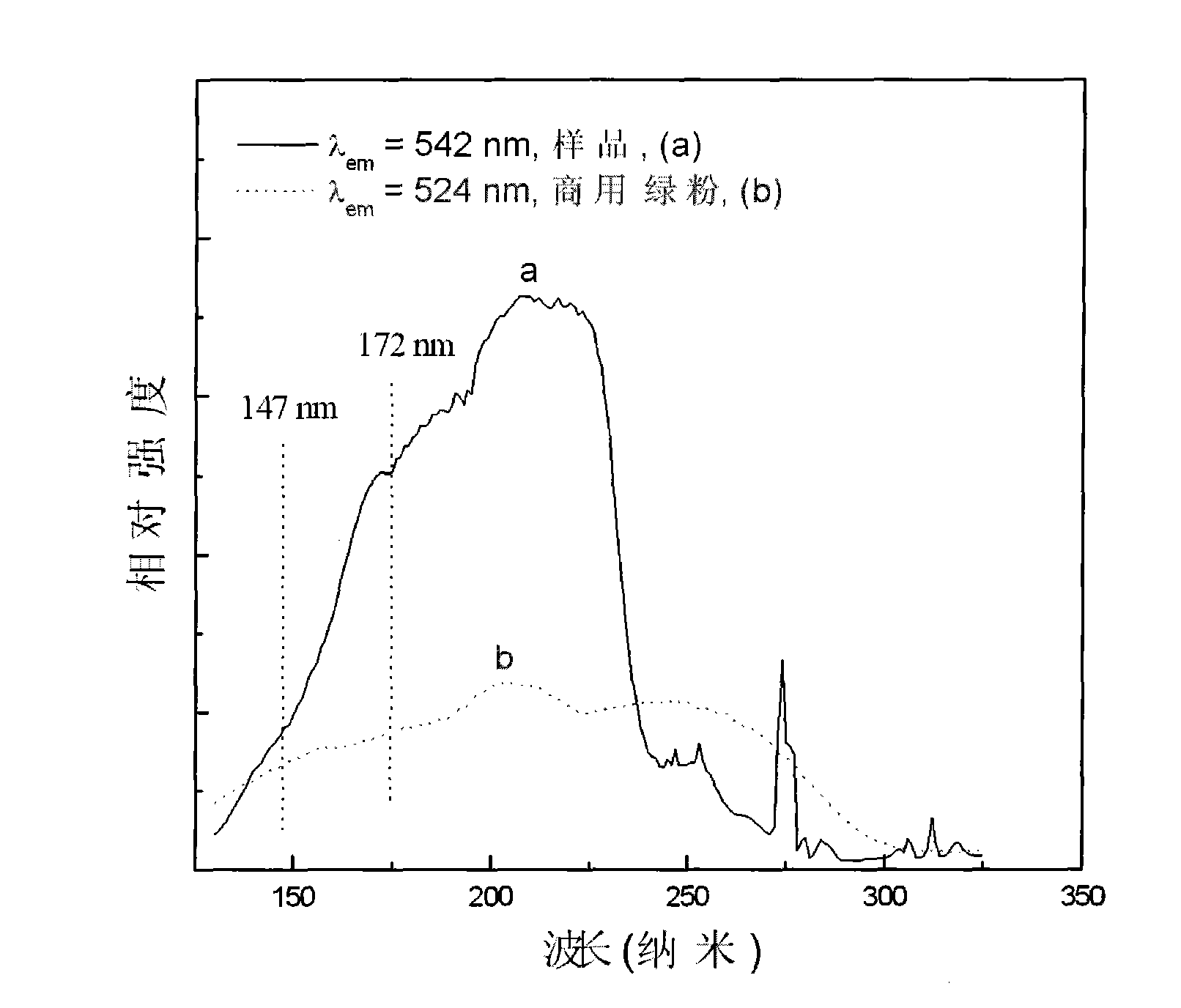

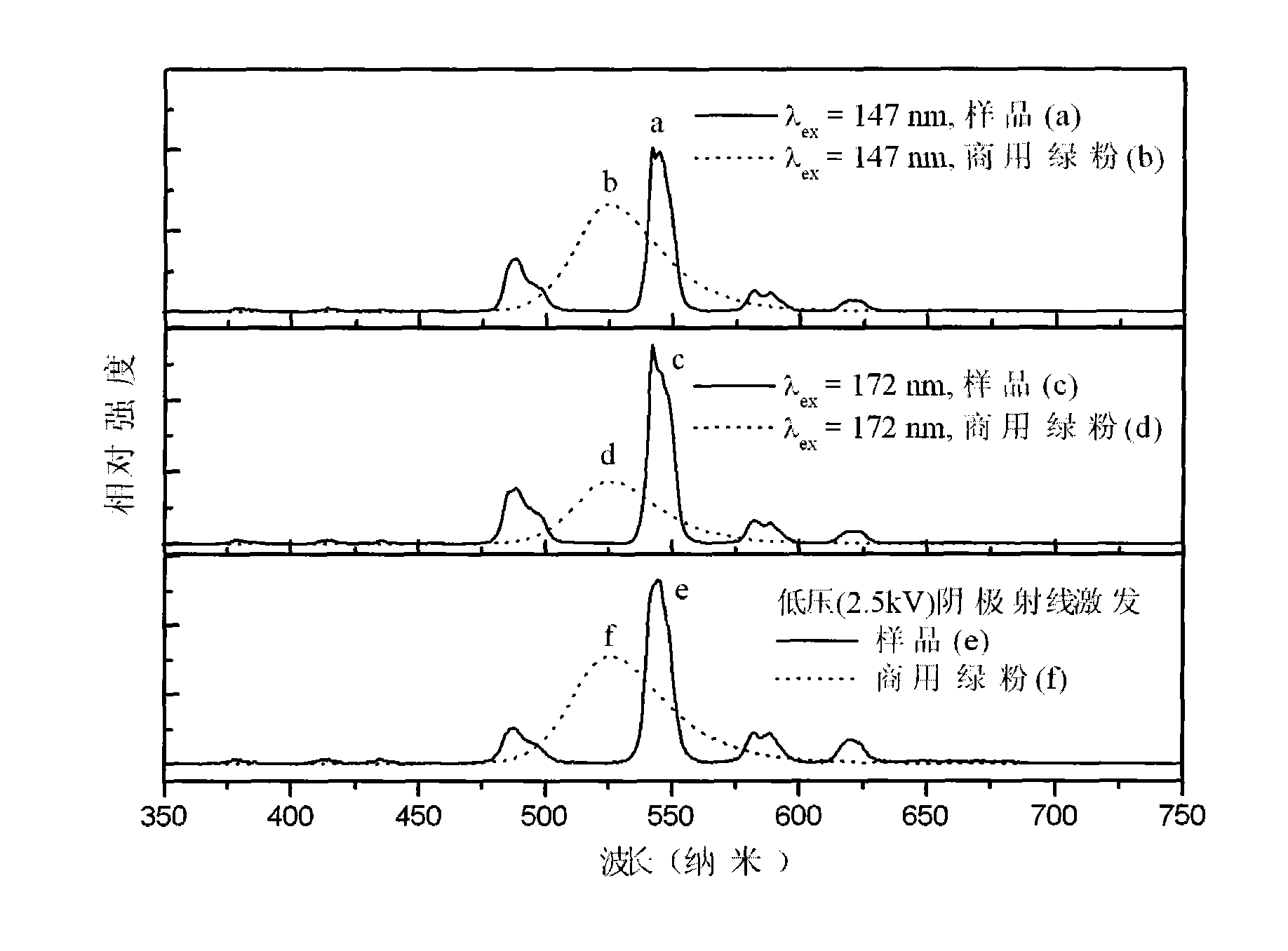

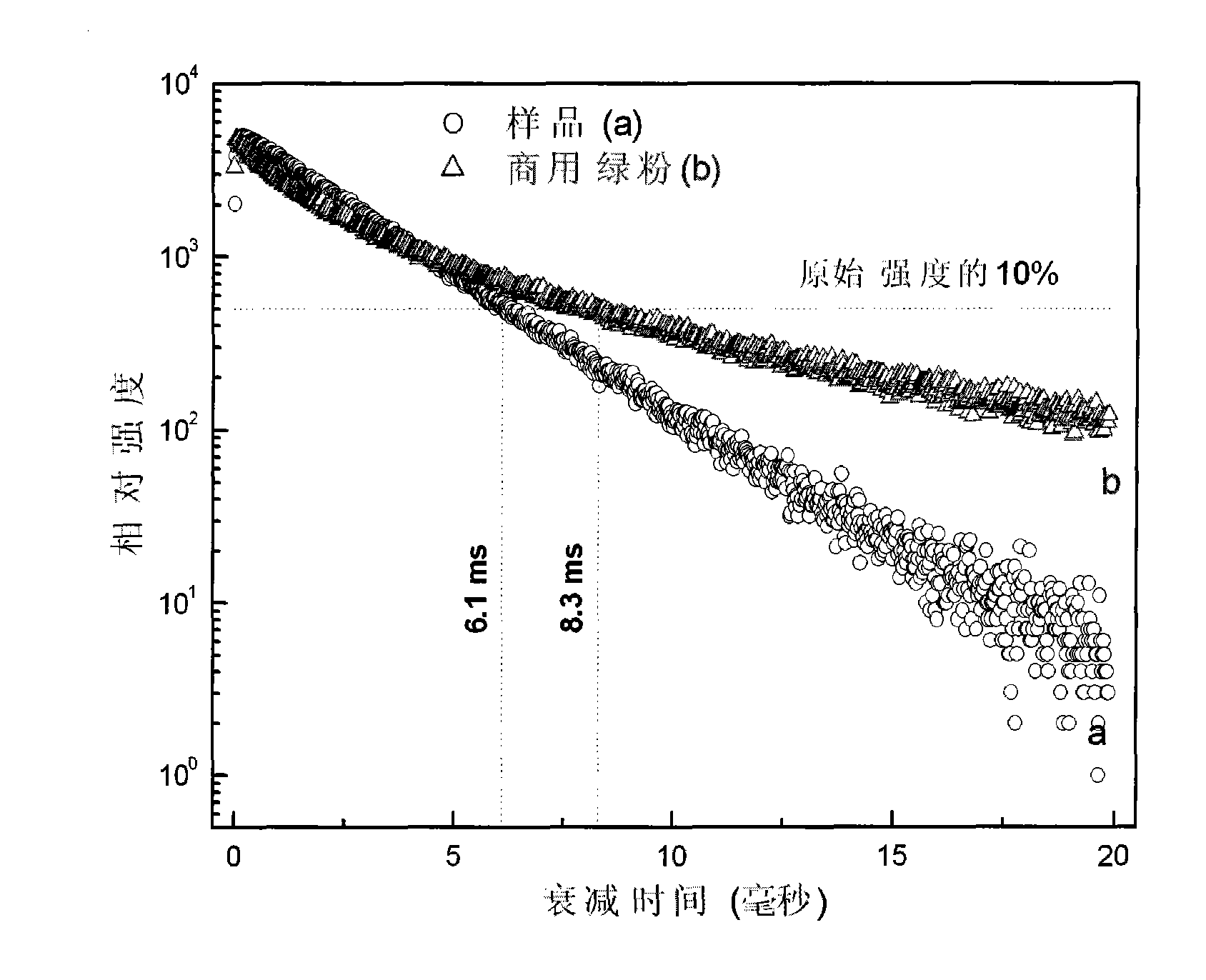

[0023] The fluorescent powder (monitoring 542nm) that embodiment 1 makes and current commercial PDP green fluorescent powder Zn 2 SiO 4 :Mn 2+ (monitoring 524nm) excitation spectrum is shown as figure 1 shown by figure 1 It can be seen that the phosphor has strong absorption at 147nm and 172nm, especially at 172nm, which is much stronger than that of Zn 2 SiO 4 :Mn 2+ , which shows that the fluorescent powder of Example 1 is in good agreement with the vacuum ultraviolet (VUV) light wavelength produce...

Embodiment 2

[0027] Weigh lanthanum trioxide (Gd 2 o 3 ) 0.6012g, terbium oxide (Tb 4 o 7 ) 0.0031g, calcium carbonate (CaCO 3 ) 1.0009g, sodium carbonate (Na 2 CO 3 ) 0.1943g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 1.1504g, ammonium fluoride (NH 4 F) 0.1729g, fully ground in an agate mortar and mixed evenly, sintered in a carbon monoxide atmosphere at 1050°C for 4 hours, cooled to room temperature, and the sample was taken out and ground to finally obtain the product.

Embodiment 3

[0029] Weigh two lanthanum trioxide (Y 2 o 3 )0.3745g, terbium oxide (Tb 4 o 7 ) 0.0031g, calcium carbonate (CaCO 3 ) 1.0009g, sodium carbonate (Na 2 CO 3 ) 0.1943g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 1.1504g, ammonium fluoride (NH 4F) 0.1729g, fully ground in an agate mortar and mixed evenly, sintered in a carbon monoxide atmosphere at 1050°C for 4 hours, cooled to room temperature, and the sample was taken out and ground to finally obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com