Method for removing heavy metal in solid organic waste compost

A technology of organic waste and heavy metals, applied in the direction of organic fertilizers, climate change adaptation, etc., can solve the problems of compost manufacturers' difficulties, shrinkage, and threats to the survival of enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

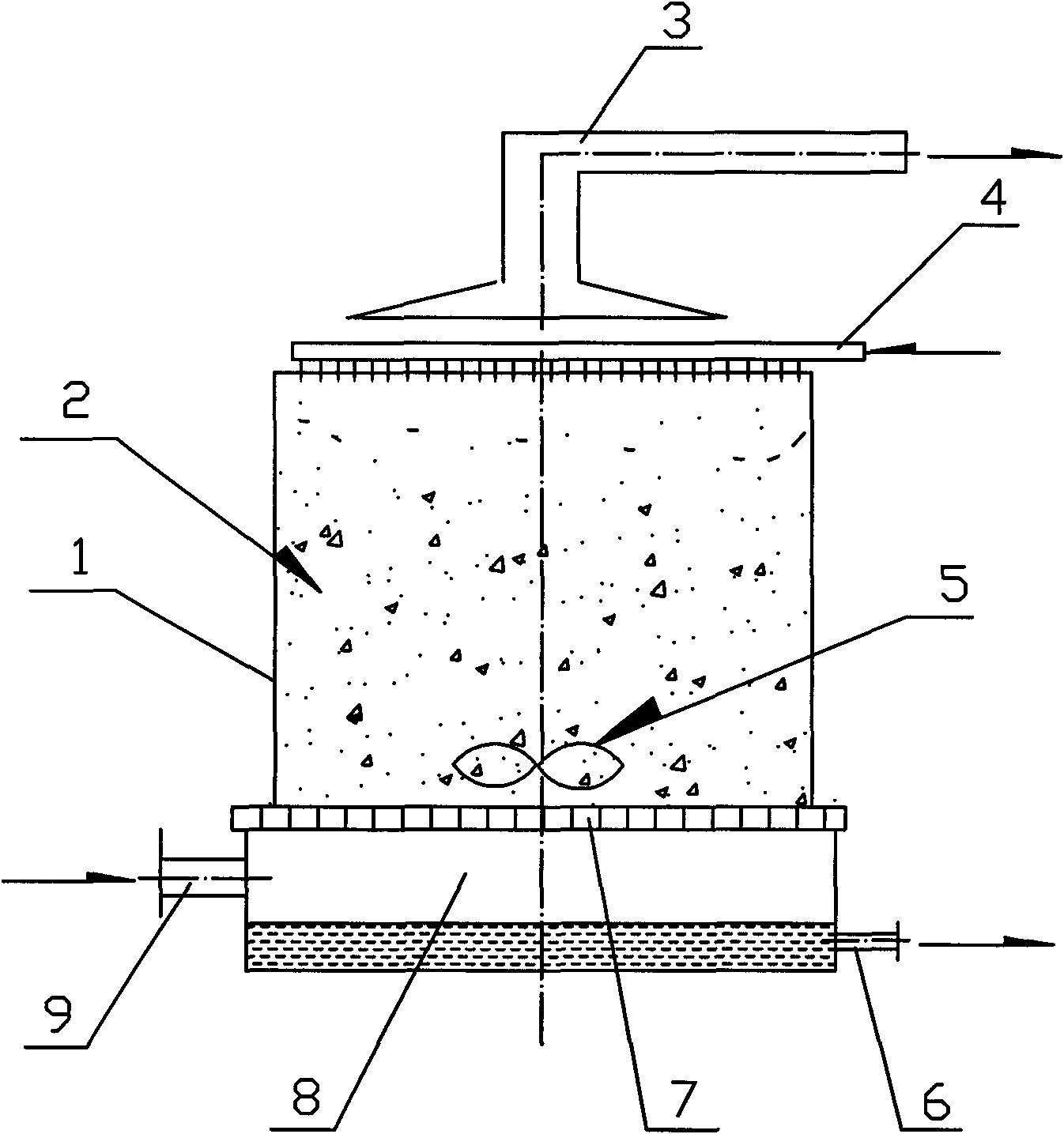

[0019] Such as figure 1 As shown, the present embodiment adopts the agricultural solid waste compost product 2, and takes 10 kg of the compost product, and its heavy metals are artificially added. After the addition is completed, it is placed on the laboratory pile bed 1. The upper end of the pile bed 1 is provided with a leaching pipe 4 and an exhaust device 3. The bottom part of the pile bed is provided with a filtrate tank 8 and a filter screen 7. The two ends of the filtrate tank 8 are An inlet pipe 9 and a liquid discharge pipe 6 are arranged respectively, and an agitator 5 is arranged in the bed.

[0020] Carry out biological leaching according to the steps stated in the technical scheme of the present invention, through 7d leaching, the removal rates of Zn and Cu are respectively 95% and 89%, which greatly reduces the concentration of heavy metals in the compost product, and the concentration of N and P The loss (in terms of total nitrogen and total phosphorus) <5%, ha...

Embodiment 2

[0022] This embodiment adopts agricultural solid waste composting products, and takes 10kg of composting products, and its heavy metals are artificially added. g / kg of finished compost. After adding heavy metals, the compost product is placed on the laboratory heap bed, and bioleaching is carried out according to the steps of the technical scheme of the present invention. After 14 days of leaching, the removal rates of Cr, Cd, and Pb are respectively 97%, 98%, and 95%. The effect is good, the concentration of heavy metals reaches the standard, and the loss of N and P is less than 10%, which has a slight impact on the fertilizer efficiency of the product. However, after the heavy metal content is greatly reduced, the application range of this compost product can be greatly expanded, and it is still of great importance for improving product quality. significance.

Embodiment 3

[0024] This embodiment adopts urban organic waste composting products, and takes 10kg of composting products, and its heavy metals are contained by itself. After preliminary testing, the types of heavy metals are Zn, Cu, Cr, Cd and Pb, and their contents are respectively 1, 0.8, 0.55, 0.1 , 0.03g / kg compost finished product, this compost product is placed on the heap bed, carries out biological leaching operation according to the technical scheme of the present invention, and each stage removal rate is as shown in the table below:

[0025] Table 1 List of heavy metal removal rates in each time period

[0026] Zn

Cu

Cr

CD

Pb

7d

85

80

43

47

37

14d

97

95

91

92

87

[0027] As shown in Table 1, after 7 days of leaching, various heavy metals have a certain removal rate, and the removal rates of Zn and Cu are significantly higher than the other three heavy metals. The res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com