Scale and corrosion inhibiting agent for circular cooling water of oxygen preparation plant as well as method and application thereof

A technology of circulating cooling water, scale and corrosion inhibitor, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. The effect of obvious technical advantages and excellent corrosion inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A scale and corrosion inhibitor (TW-301) for circulating cooling water in an oxygen plant, containing the following components: organic phosphonate, polycarboxylic acid multi-polymer, copper corrosion inhibitor, polyaspartic acid , zinc salt and water, wherein water is the solvent.

[0059] 1.1 Preparation of materials: Strictly follow the formula ratio, weigh the quantitative organic phosphonate, polycarboxylic acid multi-polymer, copper corrosion inhibitor, zinc salt and water in sequence with a metering pump, which is the preparation ①. Preparation ② is polyaspartic acid, prepared separately.

[0060] 1.2 Production: Turn on the vacuum pump, pump organic phosphonate, polycarboxylic acid multi-polymer copolymer and water into the reaction kettle, start stirring (80 rpm), and add zinc salt and copper corrosion inhibitor under stirring It is completely dissolved, continue to stir for about 20 minutes, mix well and pack separately to obtain the preparation of the presen...

Embodiment 2

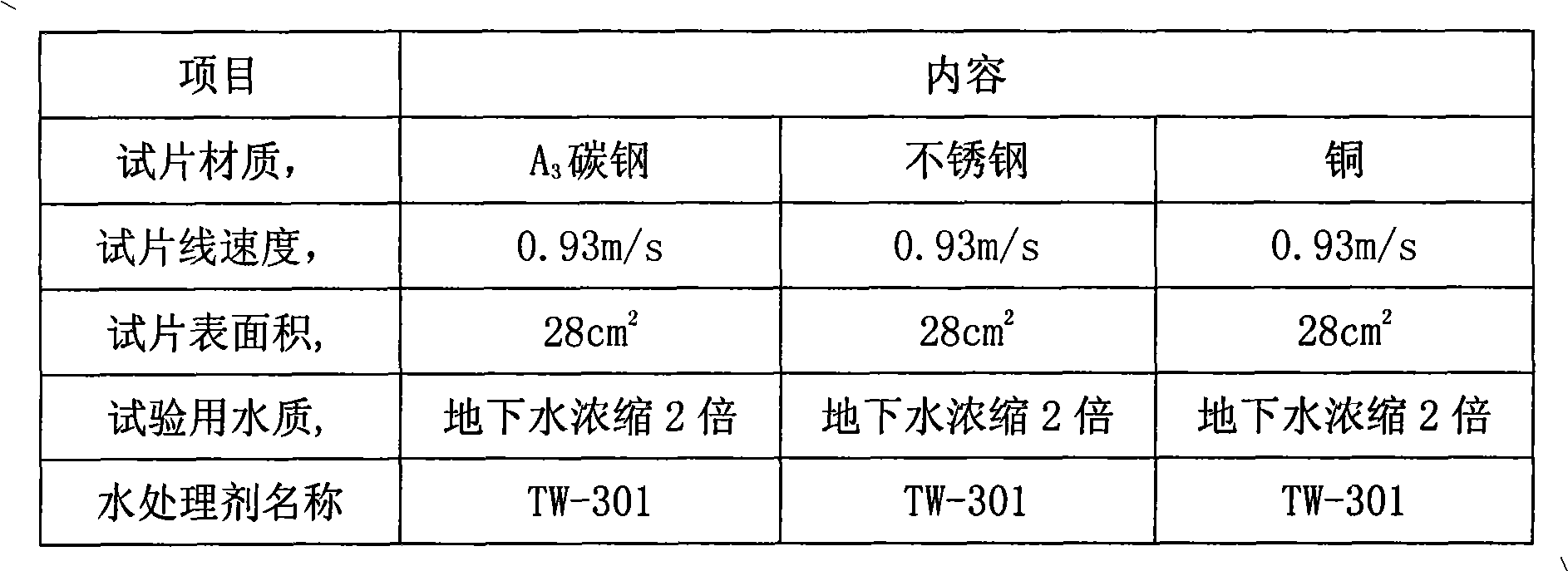

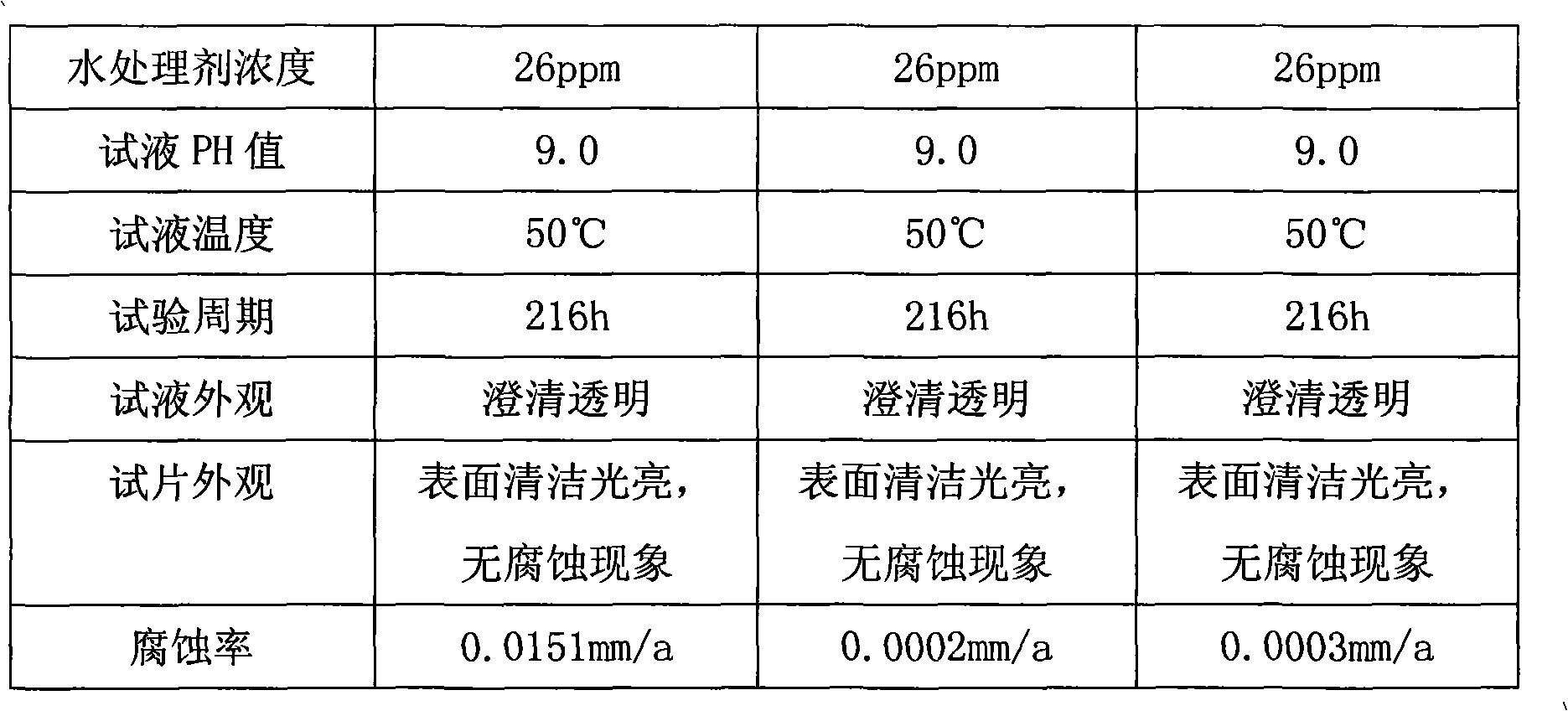

[0062] The scale and corrosion inhibitor used in the circulating cooling water of an oxygen plant according to the invention is tested for the corrosion inhibition performance of the circulating cooling water of an oxygen plant in Shijiazhuang area.

[0063] 2.1 Purpose of the test.

[0064] The method of rotating coupon corrosion test is to evaluate the corrosion inhibition performance of water treatment agent by calculating the corrosion rate and corrosion inhibition rate by using the loss mass of the test piece under the given conditions in the laboratory. The corrosion characteristics of the circulating cooling water system of the oxygen plant are investigated by using the rotating coupon corrosion measurement method, and the indicators such as the appearance color change of carbon steel, stainless steel and copper, and the corrosion rate measured by the weight loss method are comprehensively judged by the corrosion rate of the object of the present invention. corrosion pe...

Embodiment 3

[0089] 3.1 Purpose of the test.

[0090] The scale inhibition effect of the product of the present invention on the supplementary water of the circulating cooling water of the oxygen plant at different dosing concentrations was measured through the static scale inhibition test, and the formulation and dosing amount of the test were preliminarily determined.

[0091] 3.2 Test method.

[0092] The test method is carried out according to the GB / T16632-1996 standard "Determination of Scale Inhibition Performance of Water Treatment Agents - Calcium Carbonate Deposition Method".

[0093] 3.3 Test procedure.

[0094] 1. Take 2000ml of raw water collected on site and add it to the beaker, accurately add the antiscalant stock solution required for the experiment, and stir;

[0095] 2. Place the beaker in a constant temperature water bath at 60±1°C for natural evaporation and concentration;

[0096] 3. When the test solution is concentrated to 2.0 times, take out the beaker, transfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com