Preparation for oxygen sensing film and device and method for measuring micro dissolved oxygen in non-aqueous media

An oxygen-sensitive film and non-aqueous medium technology, which is applied in the field of oxygen sensors, can solve problems affecting sensor performance and achieve good reversibility, ideal flexibility, and ideal transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

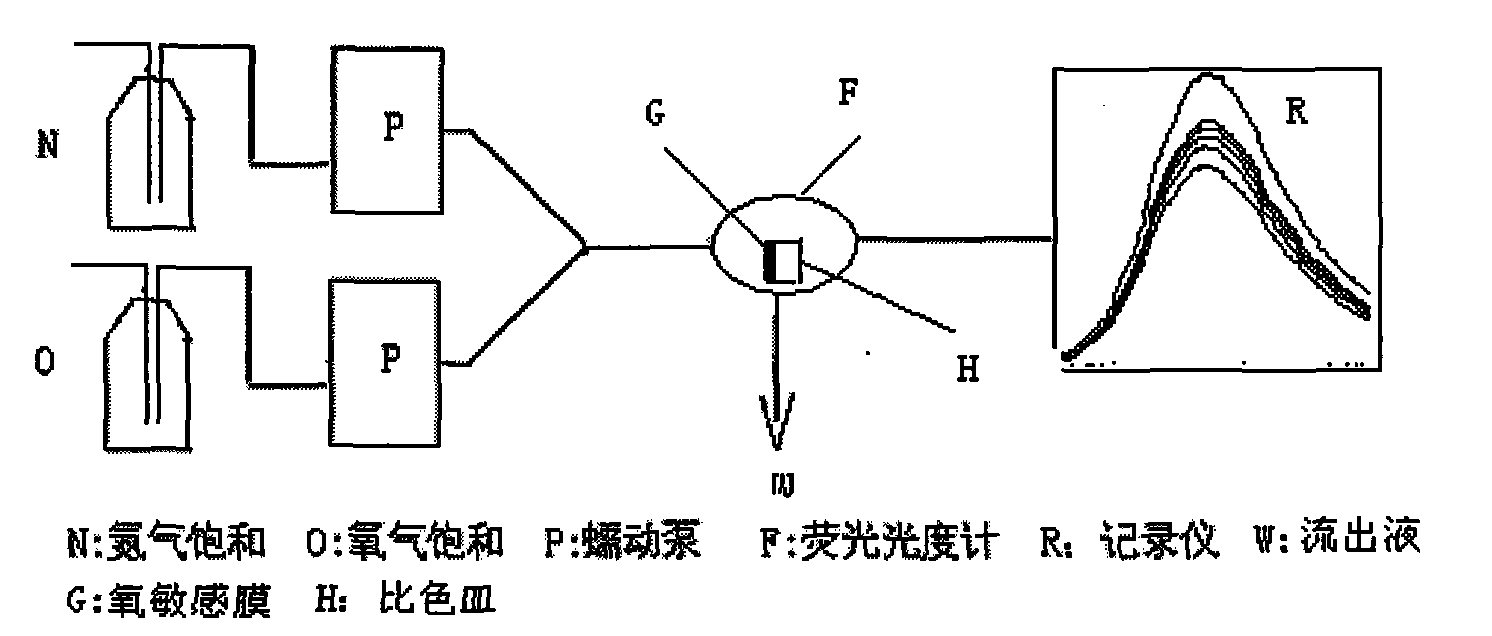

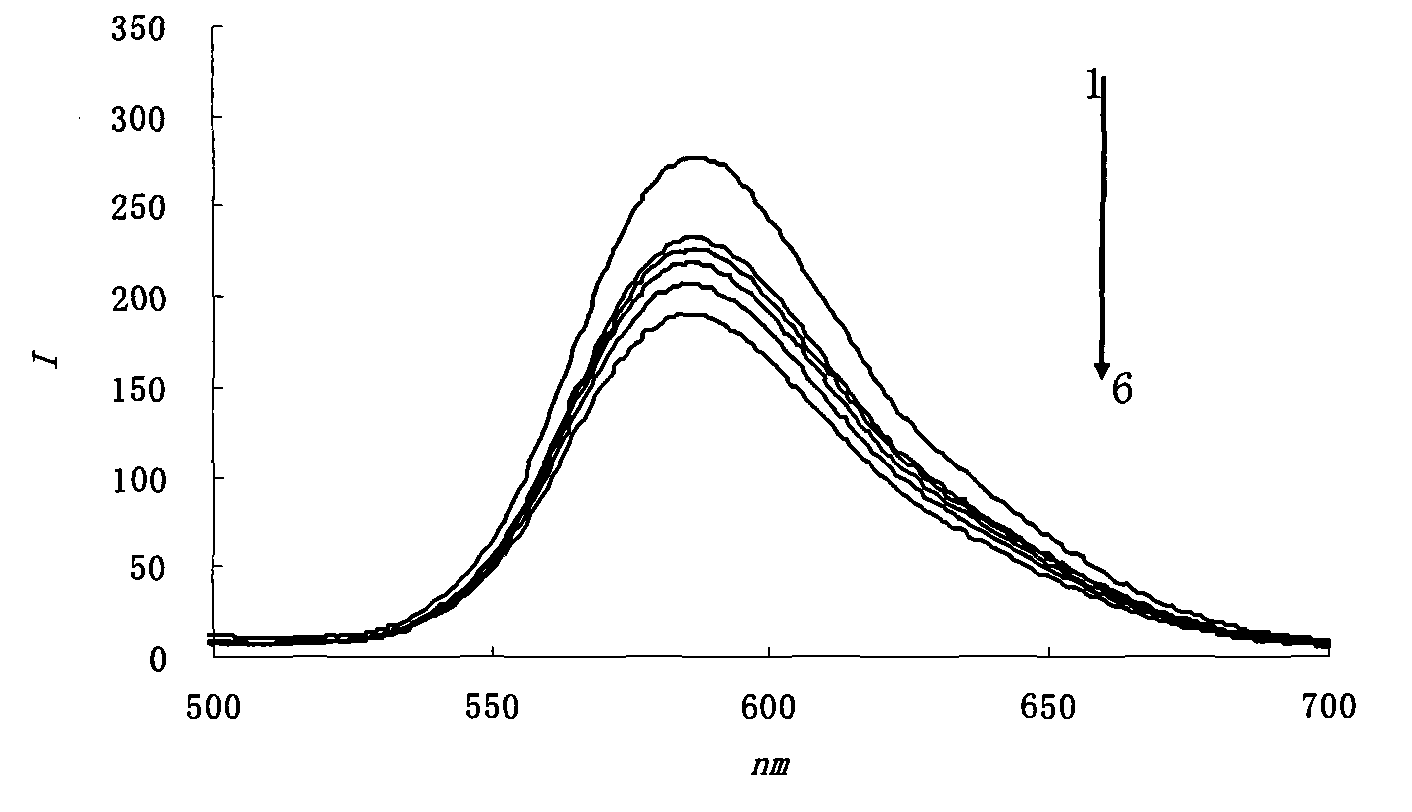

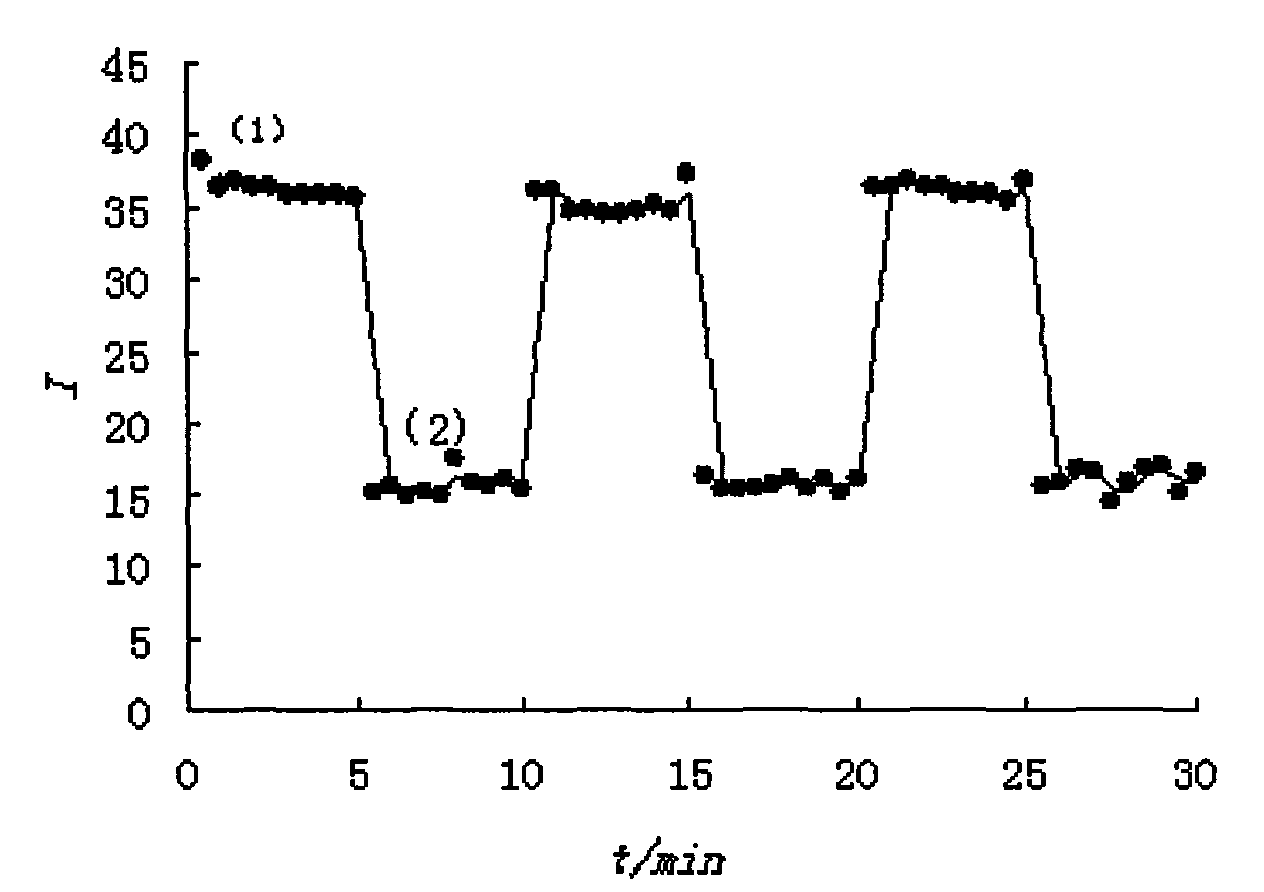

[0038] Example 1. With the prepared oxygen sensitive membrane, use figure 2 The measuring device shown measures the dissolved oxygen in 1,3-butanediol at room temperature (25°C), and the obtained Stern-Volmer curve is shown in Figure 4 .

Embodiment 2

[0039] Example 2. With the prepared oxygen sensitive membrane, use figure 2 The measuring device shown measures the dissolved oxygen in 1,2-propanediol at room temperature (25°C), and the obtained Stern-Volmer curve is shown in Figure 5 .

Embodiment 3

[0040] Example 3. With the prepared oxygen sensitive membrane, use figure 2 The measuring device shown measures the dissolved oxygen in glycerol at room temperature (25°C), and the obtained Stern-Volmer curve is shown in Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com