High nitrogen and low nickel duplex stainless steel and manufacturing method thereof

A technology of duplex stainless steel and manufacturing method, which is applied in the field of metallurgy, can solve problems such as nodules, increasing hard inclusions, affecting product surface quality, etc., and achieves the effect of convenient production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

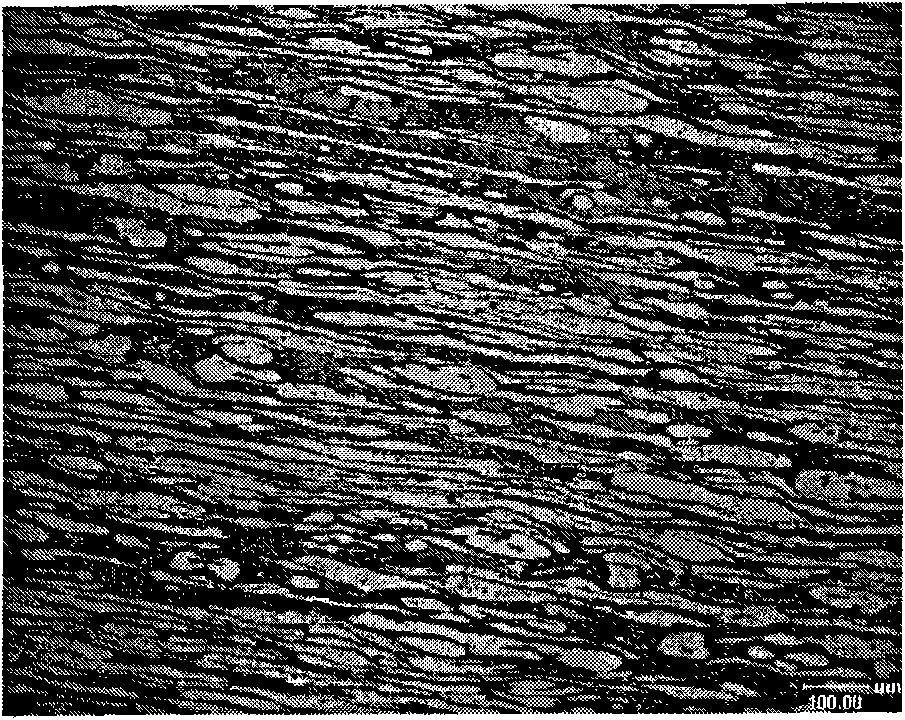

Image

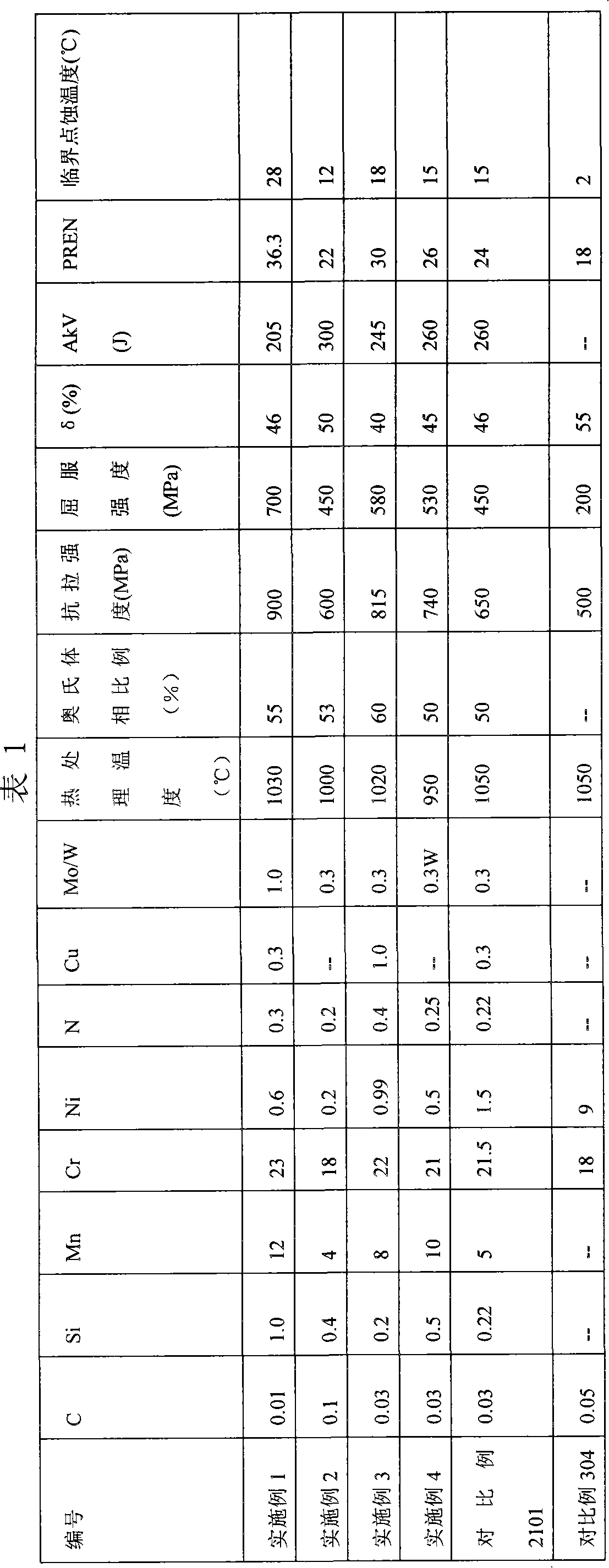

Examples

Embodiment Construction

[0030] This embodiment takes the production process of electric furnace-AOD smelting as an example: put ferrochromium, ferronickel and scrap steel into the electric furnace for melting, and after melting, the molten steel is put into the AOD furnace, and de-C, de-S and N-increasing and N-controlled blowing, when the smelting composition meets the requirements, the molten steel is poured into the tundish and cast on the vertical bending continuous casting machine. The casting superheat is 30-100°C, and the slab casting speed is 0.8-2m / min. Put the continuous casting slab into the rolling bottom feeding furnace and heat it to 1100-1250°C, roll it to the required thickness on the hot continuous rolling mill, and then coil it. Then carry out continuous pickling annealing, the annealing temperature is 950-1030°C, which is 20-100°C lower than the usual annealing temperature of duplex stainless steel, so as to ensure that the austenite content in the alloy is greater than 50%, so as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com