Photo-catalytic reaction device using ultrasonic for scale prevention and removal

A photocatalytic reaction and photocatalytic reactor technology, applied in the field of photocatalytic reaction devices, can solve the problems of corroded equipment, damage to workers' health, high cost, and achieve the effects of extending service life, reducing oxidation corrosion, and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

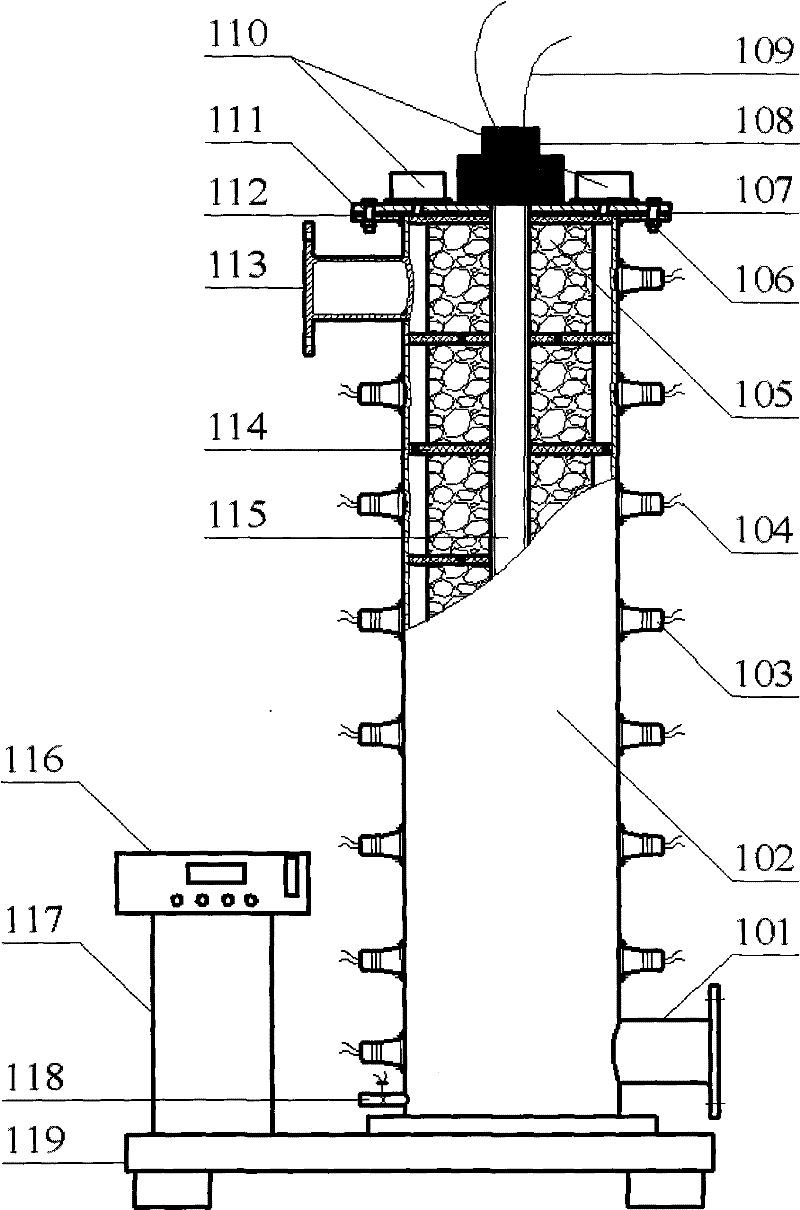

[0026] A photocatalytic reaction device using ultrasonic anti-scaling and descaling according to the present invention is mainly composed of a water inlet pipe 101, a sleeve 102, an ultrasonic transducer 103, a transmission cable 104, a metal mesh 105, a bolt 106, a gasket 107, Lamp terminal 108, power cord 109, cleaning solution box 110, top cover 111, sleeve flange 112, outlet pipe 113, metal mesh support frame 114, ultraviolet lamp 115, ultrasonic generator 116, electric control box 117, The blowdown valve 118, the base 119 and other components are composed. The device of the invention can prevent the formation of dirt on the internal metal mesh during the working process of the photocatalytic reactor, and at the same time can stop the inner wall of the photocatalytic reactor sleeve and the internal metal mesh for descaling, and has the functions of preventing the formation of fouling and destroying existing deposits. The dual role of dirt.

[0027]During online anti-scali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com