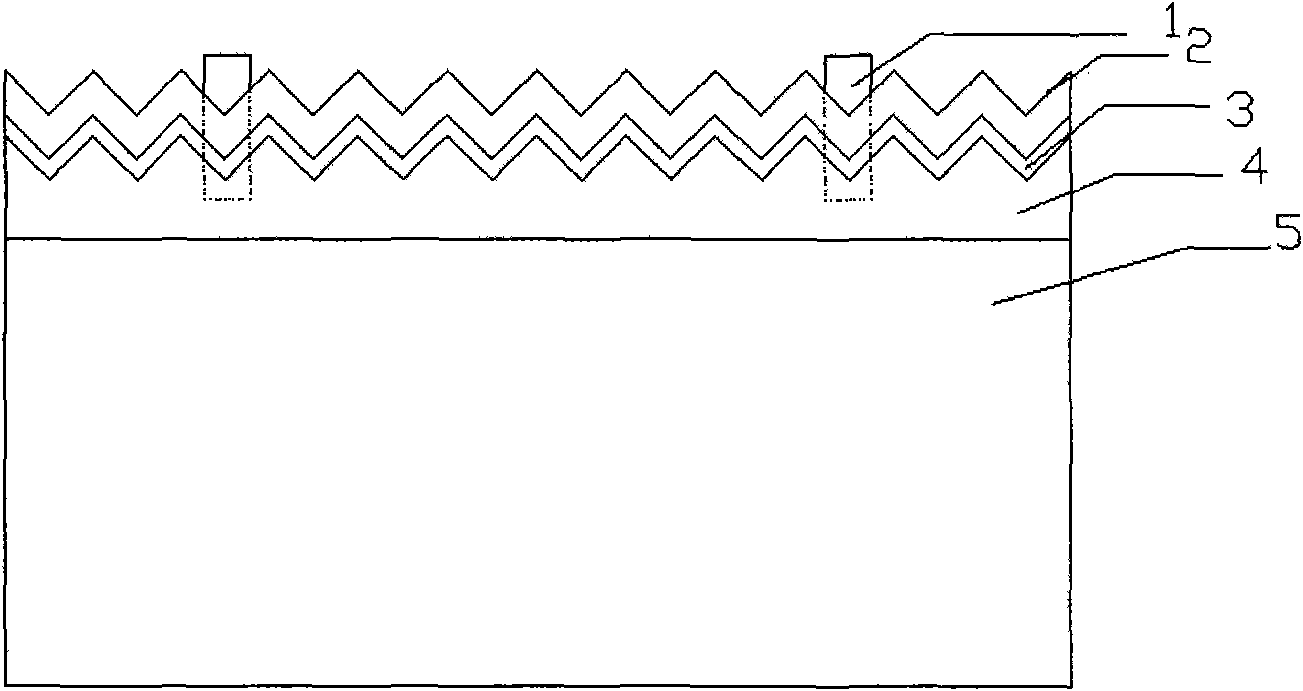

Preparation method of double-layer antireflection coating of crystalline silicon solar battery

A technology of solar cells and anti-reflection coatings, applied in the field of solar cells, can solve problems such as low reflectivity and reduced reflectivity, and achieve the effects of high power, improved photoelectric conversion efficiency, and improved absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0026] A method for preparing a double-layer anti-reflection film for a crystalline silicon solar cell, the specific steps are:

[0027] Step 1: Measure tetraethyl orthosilicate, absolute ethanol, deionized water, 36.5wt% hydrochloric acid and organic additives with a molar ratio of 1:50:10:1:0.2, and add hydrochloric acid to the Dilute in ionized water, mix tetraethyl orthosilicate and absolute ethanol, stir and heat to 100°C, add the diluted hydrochloric acid solution to the above solution in 10 times, wait for the temperature to stabilize, continue to stir for 180 minutes, cool, add organic additives Compound silane coupling agent KH-560, stir to dissolve, seal and age to obtain a sol;

[0028] Step 2: Measure tetraethyl orthosilicate, absolute ethanol, deionized water, ammonia water and organic additives with a molar ratio of 1:50:10:1:0.2, add ammonia water to deionized water and dilute Mix tetraethyl orthosilicate and absolute ethanol, stir and heat to 100°C, add the diluted...

Embodiment 3

[0033] A method for preparing a double-layer anti-reflection film for a crystalline silicon solar cell, which is characterized in that the specific steps are:

[0034] Step 1: Measure tetraethyl orthosilicate, absolute ethanol, deionized water, 36.5wt% hydrochloric acid and organic additives with a molar ratio of 1:50:10:1:0.2, and add hydrochloric acid to the Dilute in ionized water, mix tetraethyl orthosilicate and absolute ethanol, stir and heat to 100℃, add the diluted hydrochloric acid solution to the above solution in 10 times, wait for the temperature to stabilize, continue to stir for 180 minutes, cool, add organic additives Cetyltrimethylammonium bromide, N,N-dimethylformamide, and polyethylene glycol with a molar ratio of 1:1:1 are stirred to dissolve, sealed and aged to obtain a sol;

[0035] Step 2: Measure tetraethyl orthosilicate, absolute ethanol, deionized water, ammonia and organic additives in a molar ratio of 1:50:10:1:0.2, add ammonia to deionized water and dil...

Embodiment 4

[0040] A method for manufacturing a double-layer anti-reflection film for a crystalline silicon solar cell, which is characterized in that the specific steps are:

[0041] Step 1: Measure tetraethyl orthosilicate, ethanol, deionized water, 36.5wt% hydrochloric acid and organic additives in a molar ratio of 0.1:20:0.2:0.01:0.006, and add hydrochloric acid to the deionized water Dilute, mix tetraethyl orthosilicate and absolute ethanol, stir and heat to 50°C, add the diluted hydrochloric acid solution to the above solution in 10 steps, wait for the temperature to stabilize, continue to stir for 60 minutes, cool to 20°C, add moles The organic additive silane coupling agent KH-560 and cetyltrimethylammonium bromide (CTAB) with a ratio of 1:5 were stirred to dissolve, sealed and aged for 1 day to obtain a sol;

[0042] The second step: Measure tetraethyl orthosilicate, ethanol, deionized water, ammonia water and organic additives in a molar ratio of 0.1:20:0.2:0.01:0.006, add the ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com