Preparation method of TiB2/C gradient cathode material for aluminum electrolytic bath

A cathode material and aluminum electrolytic cell technology, applied in the field of electrolytic aluminum, can solve the problem of easy peeling off of the cathode material coating, and achieve the effects of solving the coating peeling defect, reducing the cost, and having strong sodium corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

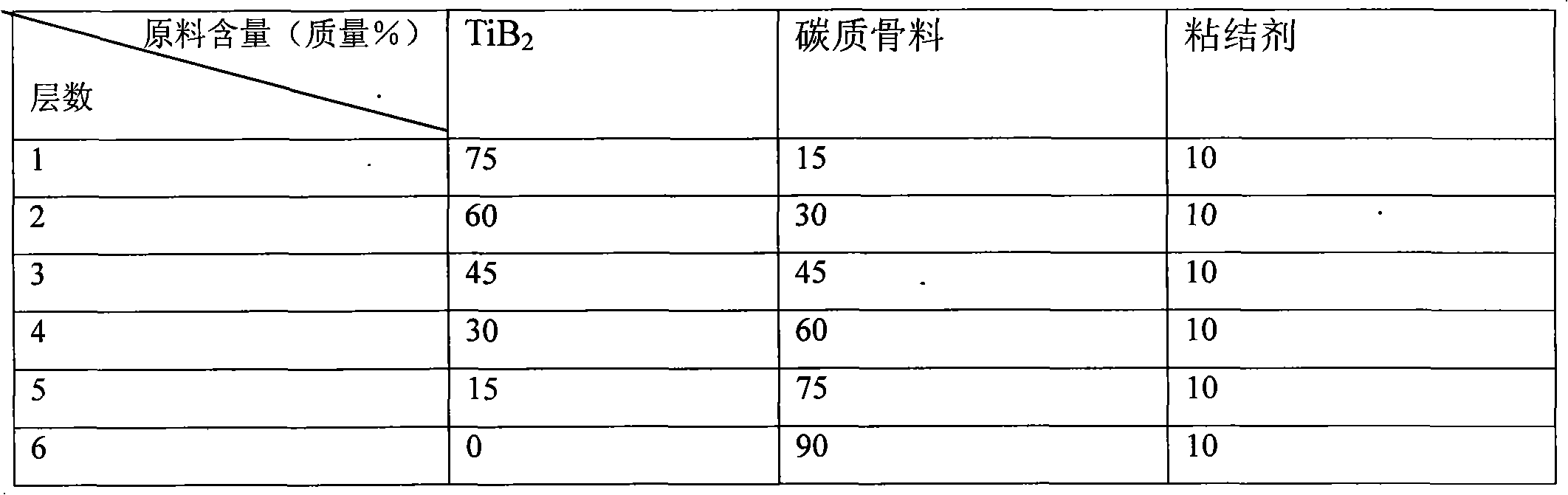

Embodiment 1

[0034] The raw material used is TiB 2 , Carbonaceous aggregates and binders.

[0035] Of which TiB 2 The particle size requirement is 100μm, and the purity is 97%;

[0036] Choose one of the following ①, ②, ③, ④ or ⑤ for the binder:

[0037] ① One of coal tar with 65% solid content, petroleum pitch with 65% solid content, coal tar with 45% coking value, epoxy resin 6101, or furan resin with a molecular weight of 4500;

[0038] ②Composition obtained by mixing epoxy resin 6101 and coal tar pitch with a solid content of 65% at a weight ratio of 1:4;

[0039] ③ A composition obtained by mixing furan resin with a molecular weight of 5000 and petroleum pitch with a solid content of 55% in a weight ratio of 1:1;

[0040] ④Composition obtained by mixing coal tar with a coking value of 40% and epoxy resin 6101 at a weight ratio of 2:1;

[0041] ⑤Composition obtained by mixing coal tar with a coking value of 45%, epoxy resin 6101 and furan resin with a molecular weight of 5000 in a weight r...

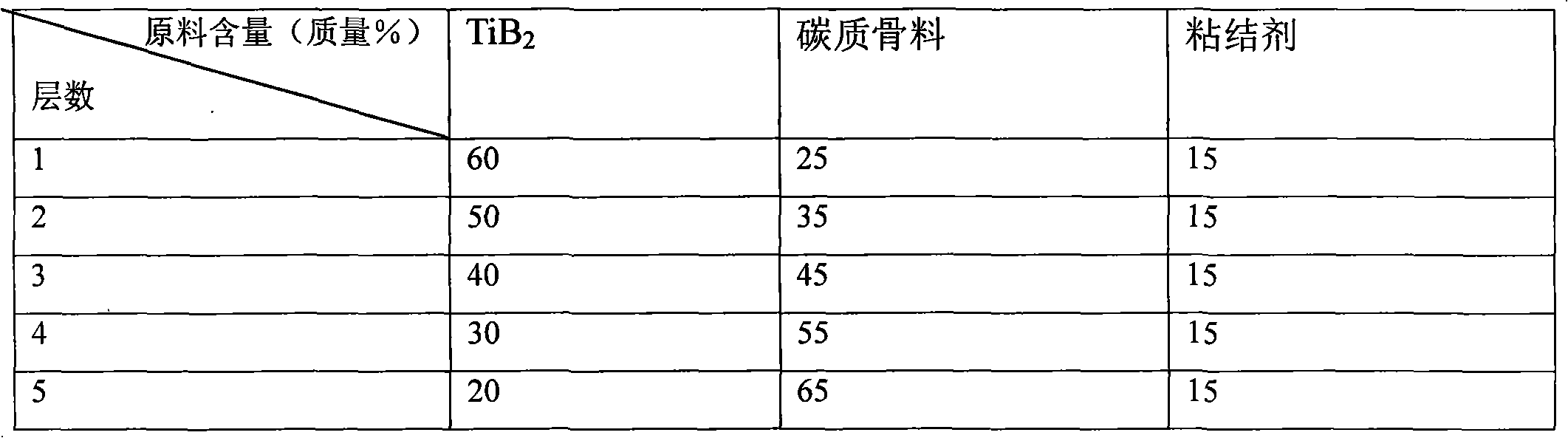

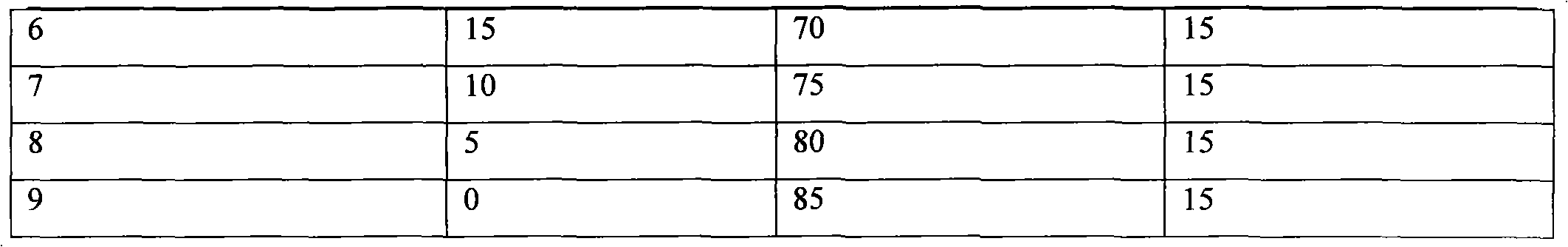

Embodiment 2

[0061] The raw material used is TiB 2 , Carbonaceous aggregates and binders.

[0062] Of which TiB 2 The particle size requirement is 10μm, and the purity is 95%;

[0063] Choose one of the following ①, ②, ③, ④ or ⑤ for the binder:

[0064] ① A composition obtained by mixing coal tar with 75% solid content, petroleum pitch with 75% solid content, and coal tar with 28% coking value in a weight ratio of 1:2:3;

[0065] ②Composition obtained by mixing epoxy resin 634 product and coal tar pitch with a solid content of 75% in a weight ratio of 3:4;

[0066] ③The composition obtained by mixing furan resin product with a molecular weight of 6800 and petroleum pitch with a solid content of 85% in a weight ratio of 3:1;

[0067] ④Composition obtained by mixing coal tar with 28% coking value and epoxy resin 634 product at a weight ratio of 5:1;

[0068] ⑤Composition obtained by mixing coal tar with a coking value of 45%, epoxy resin 634 product, and furan resin product with a molecular weig...

Embodiment 3

[0089] The raw material used is TiB 2 , Carbonaceous aggregates and binders.

[0090] Of which TiB 2 The particle size requirement is 200μm, and the purity is 97%;

[0091] Choose one of the following ①, ②, ③, ④ or ⑤ for the binder:

[0092] ①It is obtained by mixing coal tar with 75% solid content, petroleum pitch with 75% solid content, coal tar with 48% coking value, epoxy resin 6101 and furan resin with a molecular weight of 7000 in a weight ratio of 1:1:1:1:1 Compositions;

[0093] ②Composition obtained by mixing epoxy resin 6101 product and petroleum asphalt with a solid content of 90% in a weight ratio of 1:6;

[0094] ③A composition obtained by mixing a furan resin product with a molecular weight of 7000 and a petroleum pitch with a solid content of 75% in a weight ratio of 1:8;

[0095] ④Composition obtained by mixing coal tar with 48% coking value and epoxy resin 634 product at a weight ratio of 10:1;

[0096] ⑤Composition obtained by mixing coal tar with a coking value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com