Mixed yarn of cashmere and soluble fibers, preparation method and knitting product thereof

A water-soluble fiber, cashmere fiber technology, applied in textile/flexible product manufacturing, knitting, weft knitting and other directions, can solve the problems of poor spinnability of cashmere fiber, decreased fineness of cashmere fiber, shortage of resources, etc. Spinnability, improved hand feel, and effect of alleviating shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1. the preparation of cashmere and water-soluble fiber blended yarn

[0019] The index of cashmere fiber is 28-30MM, and the fineness is about 15UM. The length of the water-soluble fiber used is 38MM, and the fineness is 3D. After dyeing 95Kg of cashmere fiber and wool, add 3-3.5% wool oil, control the moisture regain at about 26%, put it for 24 hours and then mix with 5Kg of water-soluble fiber, and then immediately put it on the carding machine, spinning frame, Winding machine, twisting machine, spinning 26S / 2 finished yarn, single yarn twist 500-520T / M, double yarn twist 280-300T / M.

Embodiment 2

[0020] The preparation of embodiment 2 cashmere and water-soluble fiber blended yarn

[0021] The index of cashmere fiber is 28-30MM, and the fineness is about 15UM. The length of the water-soluble fiber used is 38MM, and the fineness is 3D. After dyeing 85Kg of cashmere fiber and wool, add 3-3.5% wool oil, control the moisture regain at about 26%, put it aside for 24 hours and then mix it with 15Kg of water-soluble fiber, and then immediately put it on the carding machine, spinning frame, Winding machine, twisting machine, spinning 26S / 2 finished yarn.

Embodiment 3

[0022] Embodiment 3 woolen flat knitting sweater

[0023] The cashmere and water-soluble fiber blended yarn prepared in Example 1 is used to weave with a 12G flat knitting machine. The weaving density is: per 100 square centimeters, the transverse density is 56 stitches, the longitudinal density is 42 turns, and the tensile density is 11.5 mesh / INCH, and the finished garment is woven Blank, then fit in 14G car, 16G sleeve collar, finishing process as follows: when washing, bath ratio 1:40, liquid wool can clean RC1.5% o.w.f, temperature 60 ℃, wash with warm water at 30 ℃ for 2 minutes, when soft , bath ratio 1:30, softener FK220-B2 2% o.w.f, smoothing agent FK-220A2 1.5% o.w.f, temperature 36°C, treatment for 20 minutes, dehydration for 3 minutes, drum drying at 75°C for 15 minutes, and ironing to a finished product. The items described in Table 1 were detected according to conventional methods in this technical field.

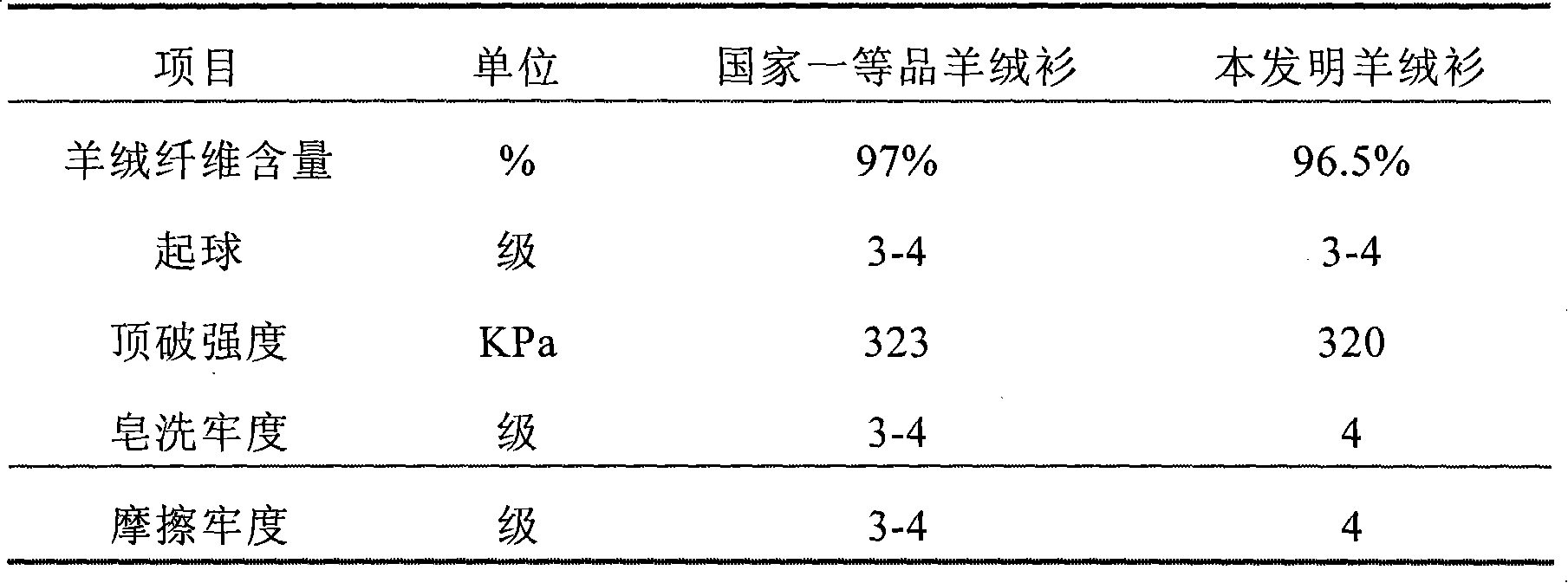

[0024] Table 1. Various tests and indicators of the fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Single yarn twist | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com